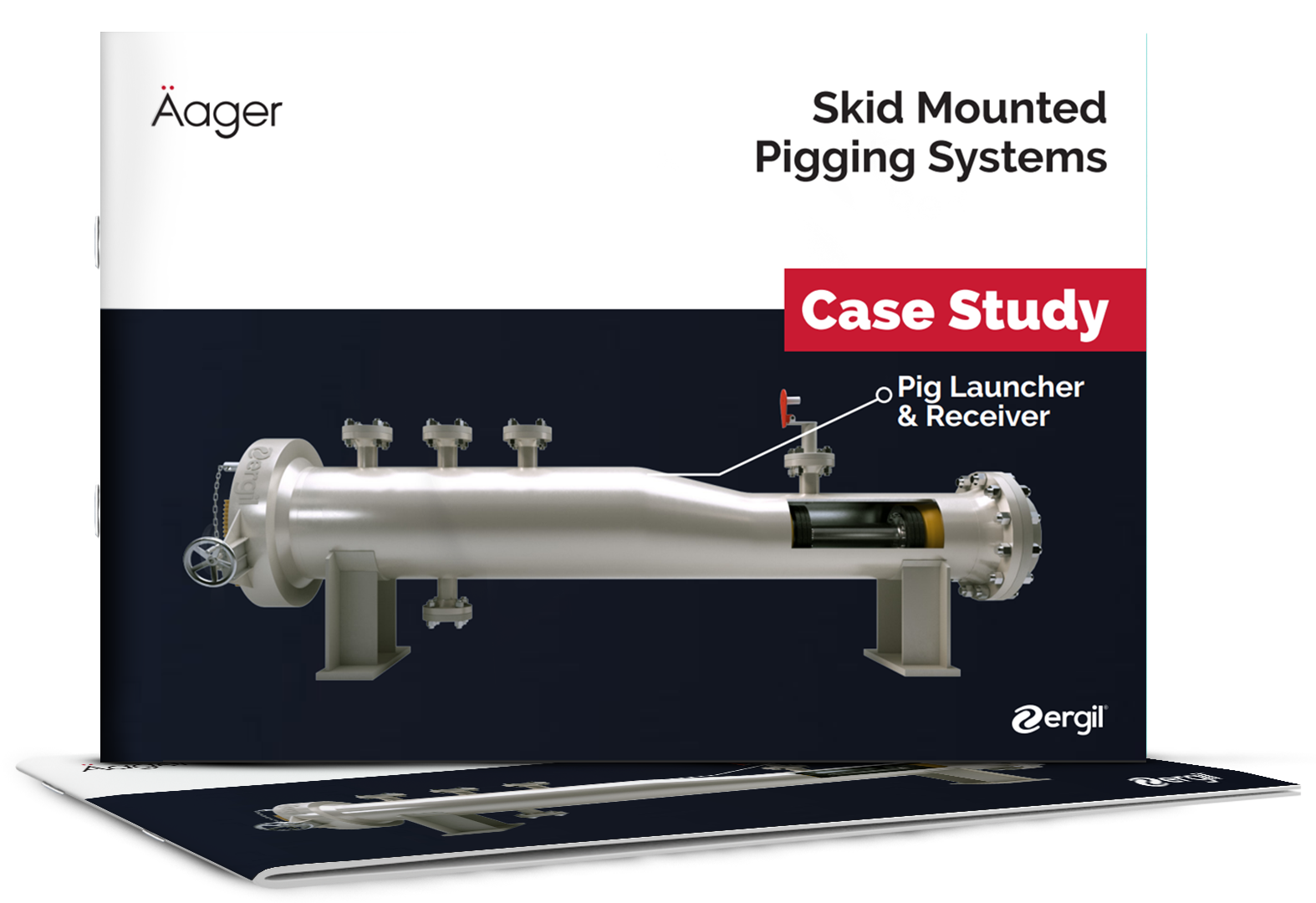

Skid Mounted Pigging Systems

Problem

An Äager Brand ERGIL, has managed to complete design, engineering and fabrication of Pig Launcher & Pig Receiver and RX Quick Opening Closure for Majnoon Oil Field Development Project carried out by Anton.

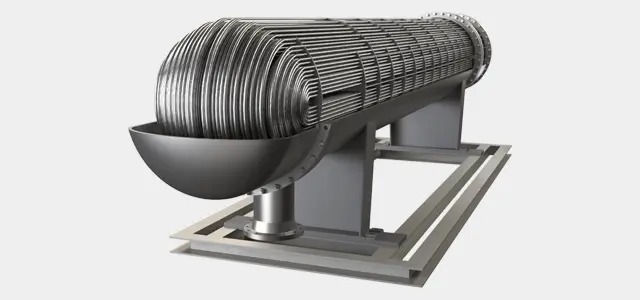

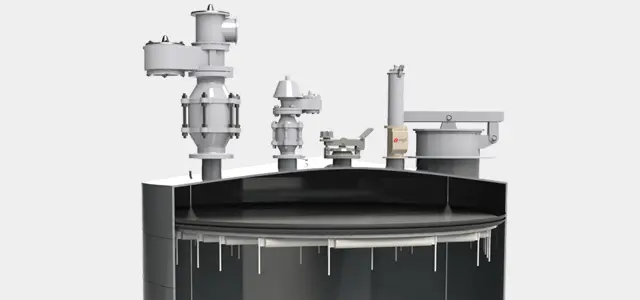

Pig launchers and receivers are one of the most important parts of pipe transfer systems and provide cleaning and inspection of piping transfer lines. Installation of these kinds of parts in the site field, sometimes, can be difficult and overcosting.

However, modular process skid is the effective way of installation with providing convenience in transportation, time, cost and control safety risks. In this project, it is tough to install equipments to the system in the site, since the project is conducted in Iraq which is far away. Mobilization, high cost, safety risk and quality control are also big isssues stem from distance.