Istanbul, Türkiye – January, 2026 — ERGIL, a leading manufacturer of engineered pressure equipment and heat transfer solutions, has successfully completed the design, fabrication, testing, and certification of special-purpose condensers for the TÜPRAŞ İzmir Refinery, Türkiye’s largest and most technologically advanced refining complex.

The project covered the complete manufacturing scope of gas-to-gas sulfur condenser shell-and-tube heat exchangers (E-9702/3 and E-9704/5), designed in accordance with ASME Section VIII Division 1 and TEMA Class “R” standards. The equipment was delivered with ASME U-Stamp, PED compliance, CE marking, and TEMA certification. All engineering, fabrication, inspection, and certification activities were carried out in strict accordance with TÜPRAŞ’s technical specifications and refinery-specific standards, reflecting the high integrity requirements of critical sulfur service applications.

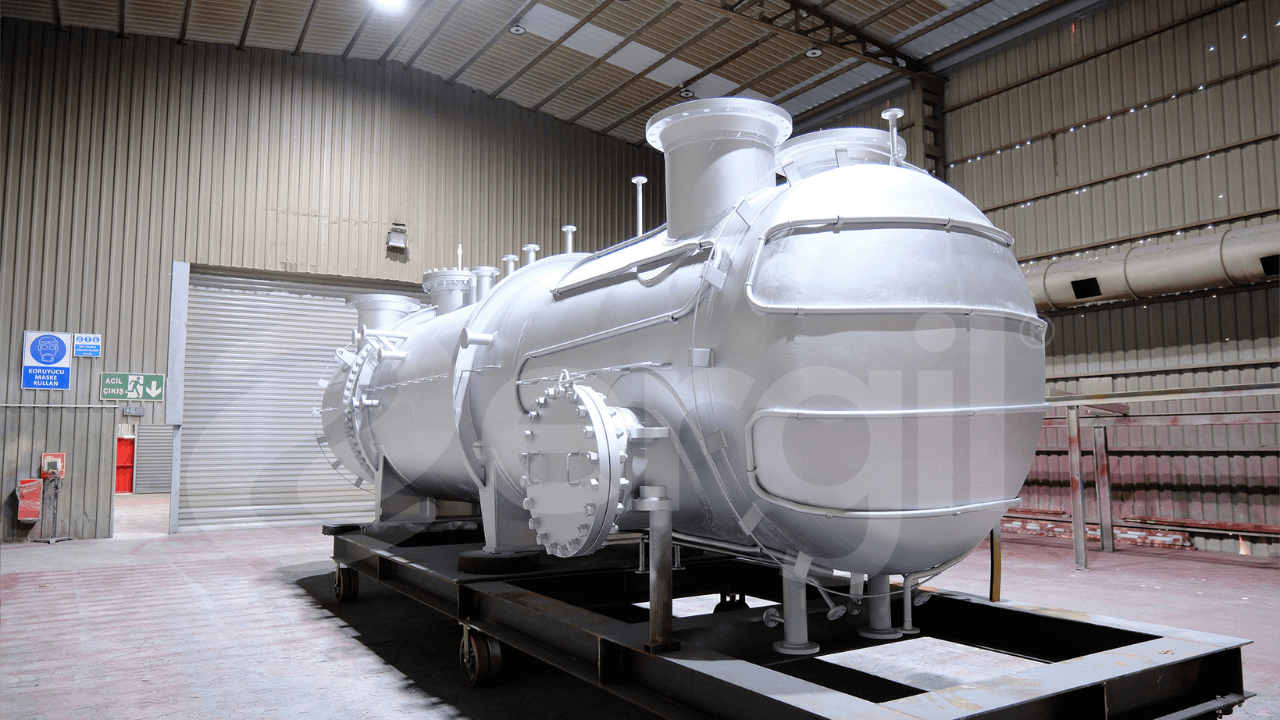

A key aspect of the project was the integration of multiple special process and material requirements, making the equipment highly demanding from both an engineering and manufacturing standpoint. The condensers were supplied with integrated demisters and refractory casting, both essential for reliable operation under high-temperature sulfur service conditions. The scope also included heating coil serpentines, enabling controlled thermal management during start-up and operation. All refractory materials and associated data sheets were reviewed and approved in accordance with TÜPRAŞ material specifications.

The equipment underwent Post Weld Heat Treatment (PWHT), including normalization heat treatment on channel heads, and was subjected to comprehensive hardness testing and impact testing, along with full compliance verification to NACE MR-0175 and HIC requirements, ensuring suitability for sour and sulfur service environments. The condensers were designed for operating temperatures ranging from 210 °C to 370 °C and a design pressure of 5.3 kg/cm²(g) on both shell and tube sides, handling sulfur process gases with ammonia-containing streams typical of refinery sulfur recovery units. A highly sensitive expansion joint system was engineered and integrated to safely accommodate differential thermal expansion, vibration, pressure fluctuations, and thermal cycling. Special attention was given to material selection, detailed mechanical design, fabrication accuracy, and inspection to ensure long-term integrity, leak-tightness, and safe operation under continuous refinery conditions.

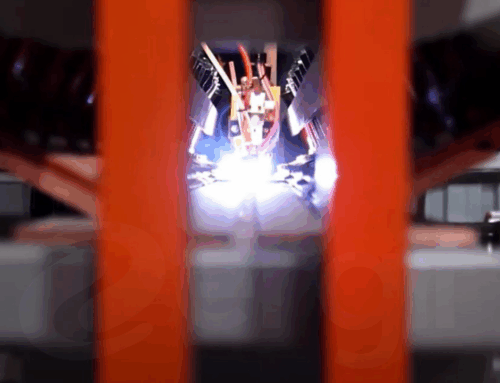

Manufacturing was performed using advanced shell-and-tube welding technologies, including high-precision automated welding machines, enabling consistent weld quality, tight dimensional tolerances, and full traceability throughout production. The equipment was manufactured using ASME-compliant materials, including SA 516 Gr.70 for shell components, SA 179 for tubes, and SA 350 LF2 Class 1 for flanges. The project required close coordination with multiple international vendors, supplying specialized materials, components, and services from different regions. Leveraging over 45 years of experience and a long-established network of qualified global suppliers, ERGIL’s procurement and project teams successfully managed this complex international supply chain while maintaining full compliance with TÜPRAŞ specifications, project schedules, and quality requirements. All required non-destructive examinations, hydrostatic tests, and final inspections were completed in accordance with applicable codes and TÜPRAŞ requirements, with results fully documented and certified prior to delivery.

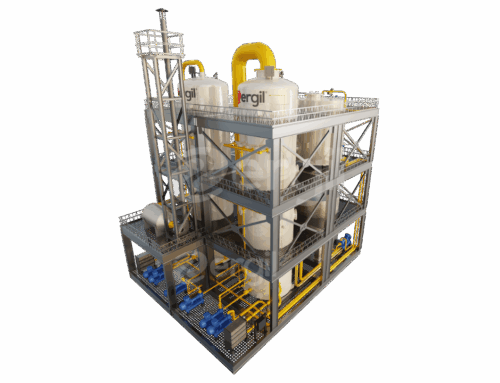

The successful completion of this project demonstrates ERGIL’s capability to deliver complex, refinery-grade heat transfer equipment involving advanced materials, stringent testing regimes, specialized fabrication processes, and effective coordination of international vendors.

Commenting on the project, Yusuf Selimoğlu, Project Coordinator Head at ERGIL, stated:

“This project is a clear example of what can be achieved through strong teamwork and a truly multi-disciplinary approach. Our engineering, manufacturing, quality, procurement, and project management teams worked in close coordination to successfully deliver a highly specialized gas-to-gas sulfur condenser under demanding refinery conditions. ERGIL’s in-house engineering depth, advanced manufacturing capabilities, and long-standing expertise in handling challenging process gases such as sulfur were key factors in meeting TÜPRAŞ’s stringent technical and quality requirements.”

By combining detailed engineering, ASME-certified manufacturing, and rigorous quality assurance under one roof, ERGIL continues to be a trusted partner for critical equipment applications in Türkiye’s refining and energy infrastructure.

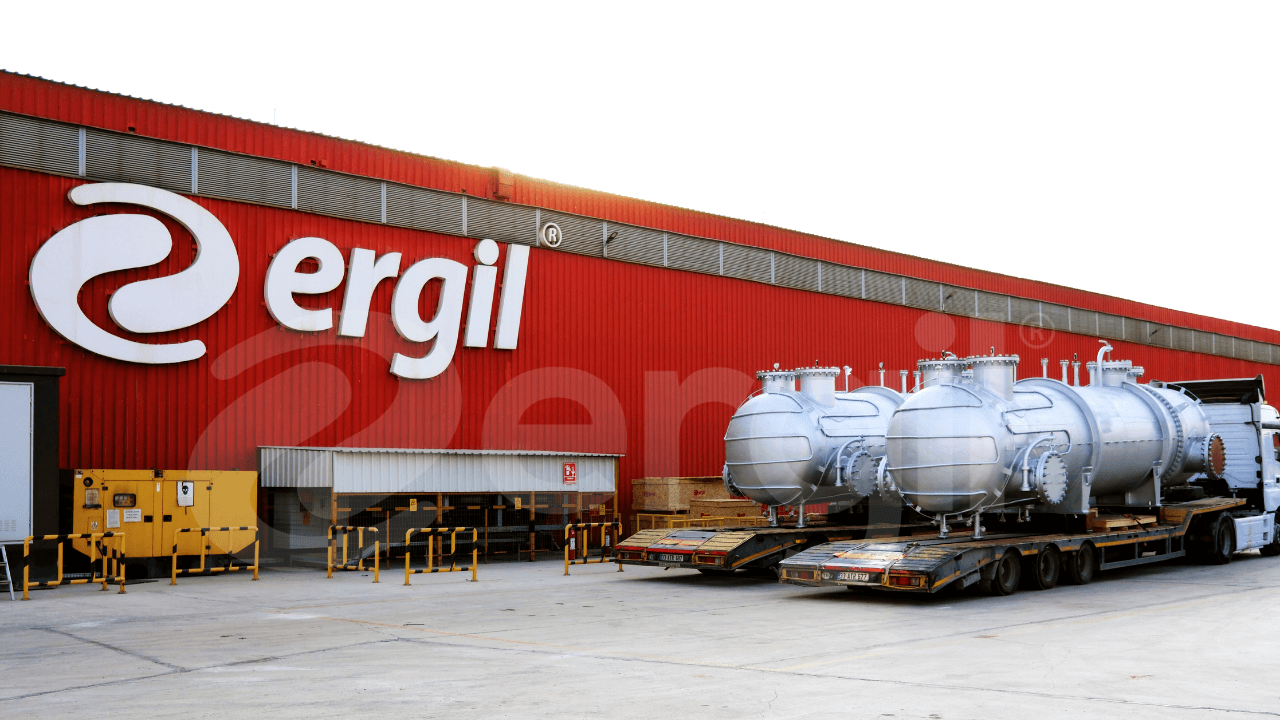

About ERGIL

ERGIL is a globally active engineering and manufacturing company specializing in pressure vessels, shell-and-tube heat exchangers, pigging systems, storage tank equipment, and emission control solutions for the oil & gas, refining, energy, and industrial sectors. With ASME-certified manufacturing facilities and decades of experience, ERGIL delivers custom-engineered solutions that meet the most stringent international and client-specific requirements.