AI is reshaping energy by turning real-time data into better decisions. ERGIL’s role is to make this practical at the asset level. We pair proven tank equipment and emission-control hardware with a simple digital layer that improves safety, compliance and uptime—without adding complexity.

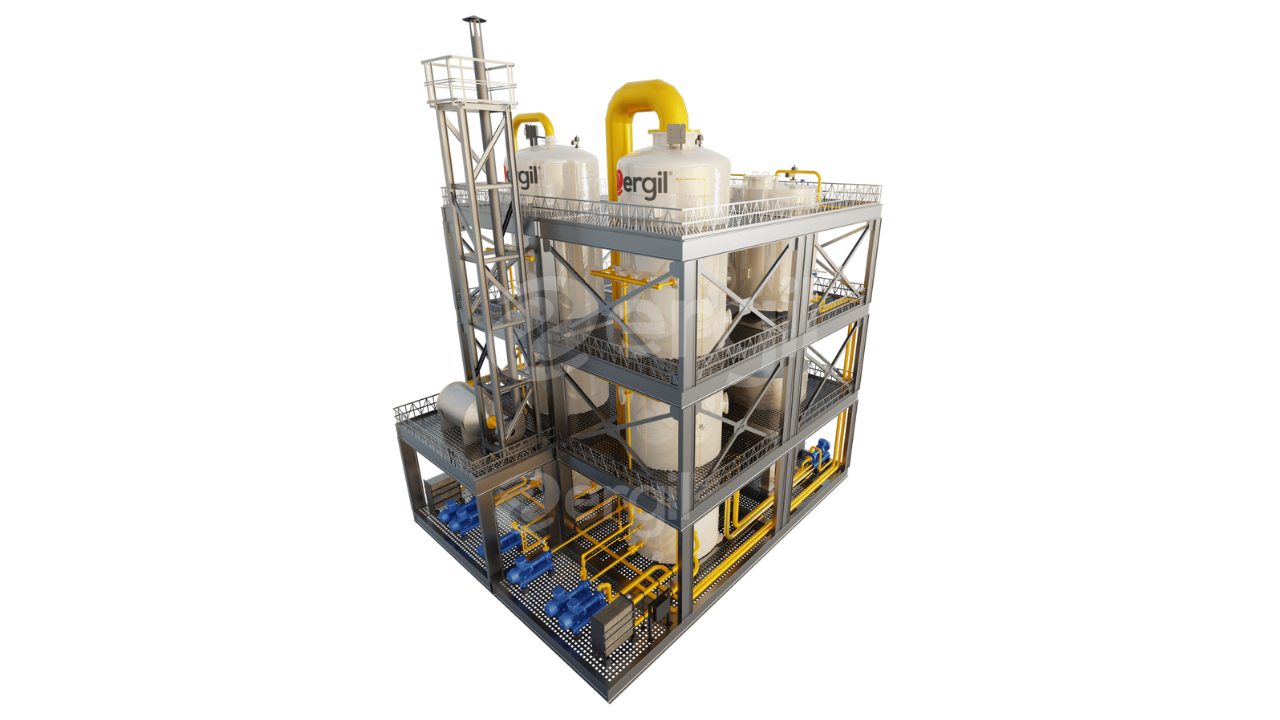

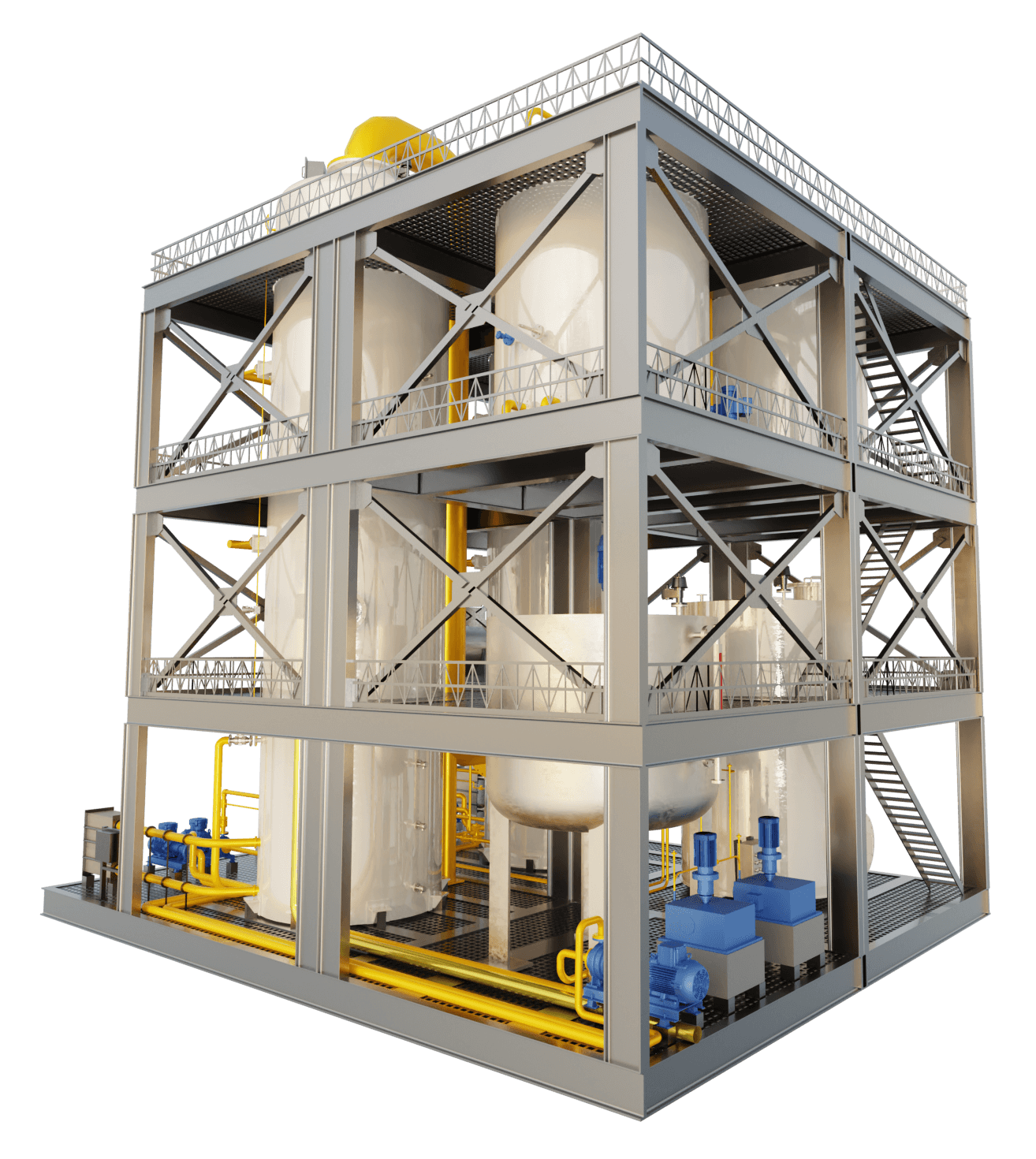

Our solution in brief. ERGIL Insight is a lightweight monitoring and analytics suite for storage tanks and emission controls. It ingests sensor and control-system data from floating roof seals, venting devices and scrubbers, then applies AI models to spot anomalies, predict failures and recommend set-point adjustments. Operators get early warnings on seal degradation and fugitive emissions, suggested maintenance windows, and auto-generated compliance reports. Results: fewer leaks, fewer unplanned shutdowns, and lower operating cost.

What’s next. Three AI trends matter most now and over the next decade:

- Autonomous optimization of critical equipment (staying in spec as feed and ambient conditions change).

- Predictive maintenance that prioritizes the right intervention at the right time, reducing solvent and spare-parts consumption.

- Measurement & verification that quantifies emissions reductions with audit-ready data.

At ADIPEC 2025. We will demo ERGIL Insight working with our latest floating roof sealing systems and emission-control devices. Visitors will see live dashboards, anomaly alerts, and one-click reports that shorten investigations from days to minutes. The focus is practical: how to deploy fast, connect to existing PLC/SCADA, and show impact within a single turnaround cycle.

Collaboration to scale impact. Real progress needs energy operators, technology providers and finance to align on outcomes. Standard data models, open interfaces and performance-based contracts can fund upgrades from verified savings and avoided emissions, accelerating roll-outs across fleets—not just at a single site.