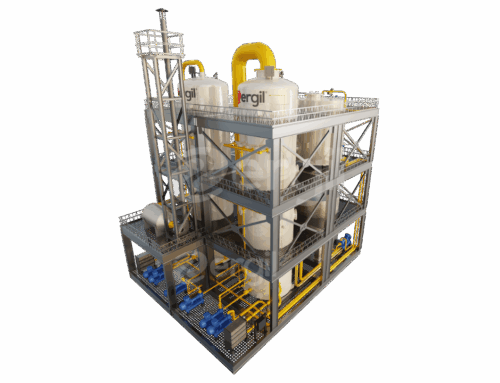

Collaborating with Petronas for a major oil field project in Gharraf, Iraq, ERGIL proudly announces its victorious completion of delivering skid mounted pig receiver and pig launcher accompanied by whole instrumentation and Pig Handling System for the Iraq oilfield. Located at the northwest of Al-Refaei, Gharraf is ranked as the fifth largest oil and gas field in Iraq with reserves estimated to 1 million barrels of oil equivalent.

The scope of work of this major project included 1 6” x 8” Pig Launcher complete with interconnecting piping and valves within the skid, 1 6” x 8” Pig Receiver complete with interconnecting piping and valves within skid, Pig Trolleys, Jib Cranes and Spare parts for start-up and commissioning. ERGIL Pig Receiver & Launchers are easy to use and install, are made of corrosion resistant materials, thus providing complete solutions for all pipeline related jobs such as cleaning, drying, testing and displacement. On the other hand, ERGIL’s Pig Handling and Pig Trolley systems help to handle and unload the pigs using manpower thereby reducing work accidents. They are designed and manufactured to meet the requirements of each client.

Nallinikanth, Business Development Manager, ERGIL on this project said that its association with Petronas on the Gharraf oil field project has been very promising. The region has a lot of potential, it hopes to announce many such accomplishments in the near future. He believes the right partnership in such projects can go a long way in the success of each project.

With a legacy dating back to 1983, ERGIL is one of the leading companies into the manufacturing of tanks, tank equipments and accessories for storage tank terminals, refineries, pipelines, process and industrial plants. Having exported to more than 60 countries around the world, it carefully upholds its international standards while providing complete solutions for the oil, gas, power, construction and chemical industries.

Its 32,000 sq/m facility in Mersin, Turkey and team of experienced professional engineers and management enables them to bear and meet complex projects and deliver with ease. As a modern facility it is equipped with the latest technology, including fully automated welding, rolling, CNC plasma cutting, shot blasting, heating, painting system and lifting machines. ERGIL is also capable of handling in-house pressure testing, radiography, and other non-destructive tests.