What is a Bioscrubber?

Bioscrubber, a system used to treat odor-causing gas pollution by biological means, works through a biological mechanism rather than a chemical or physical process.

The microorganisms used for the biological process are generally selected according to the type of pollutant and convert pollutants into harmless compounds, using them as a source of energy and nutrients. It is mostly used to treat gases such as hydrogen sulfide (H₂S), volatile organic compounds (VOCs), ammonia (NH₃) and sulfur compounds at high flow rates and concentrations.

The Main Advantages of Bioscrubber

- Pollution does not accumulate on the packing material

- Can applied large gas flow rates and high contaminant concentration

- Can operate continuously and maintenance needs are minimal

- Do not produce chemical waste

- Low energy consumption

Function

- Both particulate and waste polluting gasses can be cleaned.

- Particulate matter is removed up to 80%.

- The system can be controlled with systems such as IoT and SCADA.

- Precision pH control.

- Capacities of 200.000 m3/h.

- Pollutant gasses can be cleaned at a rate of 99%.

Working Principle of Bioscrubber

- The packing materials create a structure which directs the polluting gas to enter the system at the base and flow up through it.

- The packing materials are evenly soaked in the surface of the packing materials by the cleaning solution, which is sprayed from the spray nozzle. Bacteria create a filmed surface at the packing rings

- The packing rings' form creates a large contact area between the bacteria and the gas.

- The bacteria spread homogeneously on the surface of the packing materials.

- The nutrient solution accumulated in the tank is sent back to the system by means of the pump, and the circulation continues in this way.

- The nutrient solution, whose chemical properties change over time, is discharged out at regular intervals and a new nutrient solution is added to the system again.

- Finally, the cleaned gas leaves the system by passing through the demister.

H2S, NH3, and (VOC)s can be removal by using different type bacteria. For this, the Thiobacillus familia for H2S, the Nitrosomonas and Nitrobacter bacteria familia for NH3 and Pseudomonas, Bacillus, and Arthrobacter the bacterias familia for VOCs are commonly used.

Bioscrubber Applications Area

In general, wherever air containing volatile organic compounds and odorous substances is generated, biological scrubbers are used.

- Wastewater Treatment Plant (WTPs) Odors

- Waste management plants

- Petrochemical Refineries Odors

- Chemical Industries Odors

- Tobacco Industries

- Food Industries

- Biogas Production Plant

- Treatment of Flue Gases

Design Features

- FRP, HDPE, PP type used tower construction based on dirty gas type.

- PLC control for continuously operating systems.

- Minimal manual intervention while in operation.

Corrosion-resistant and ATEX equipment according to customer requirements.

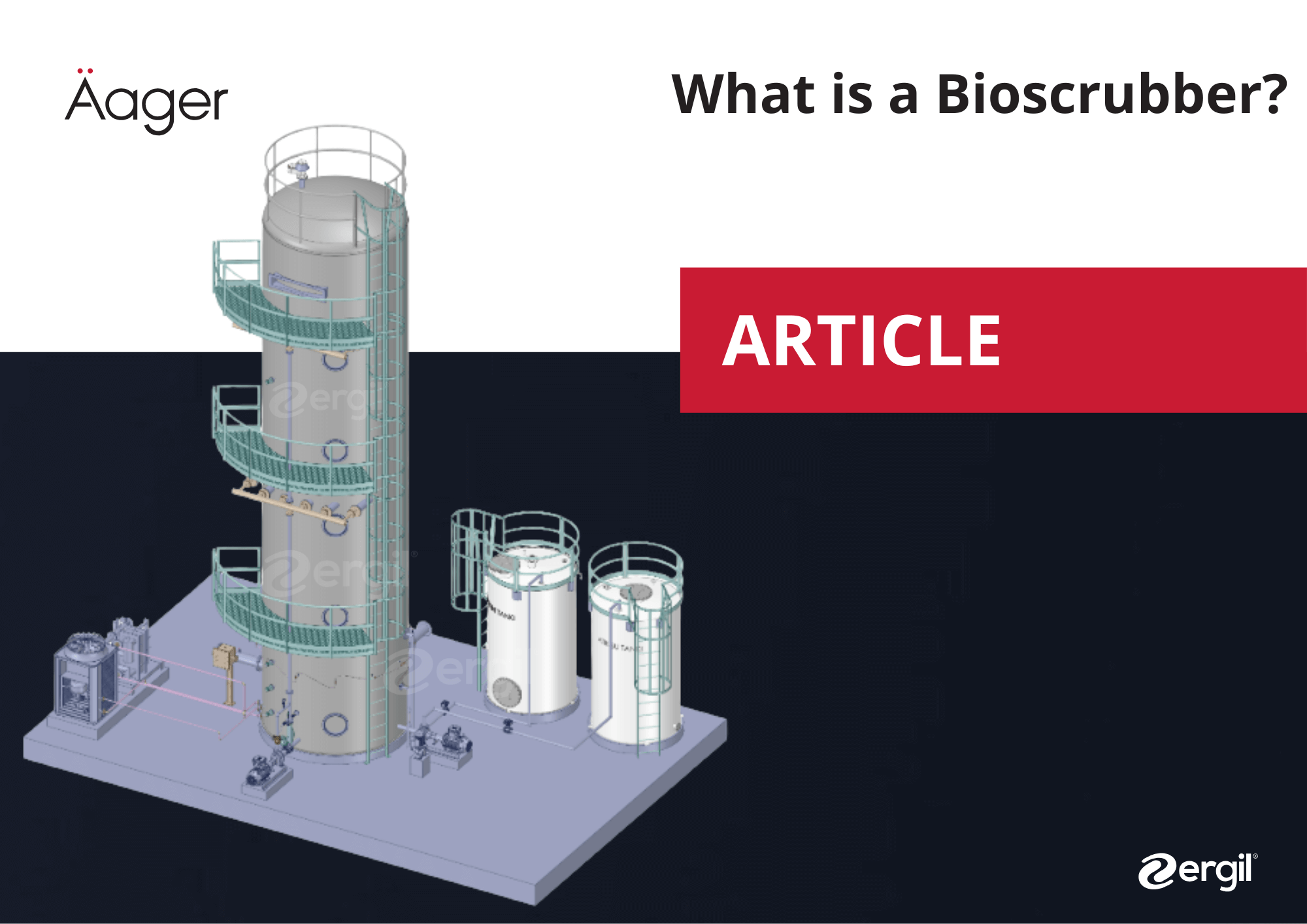

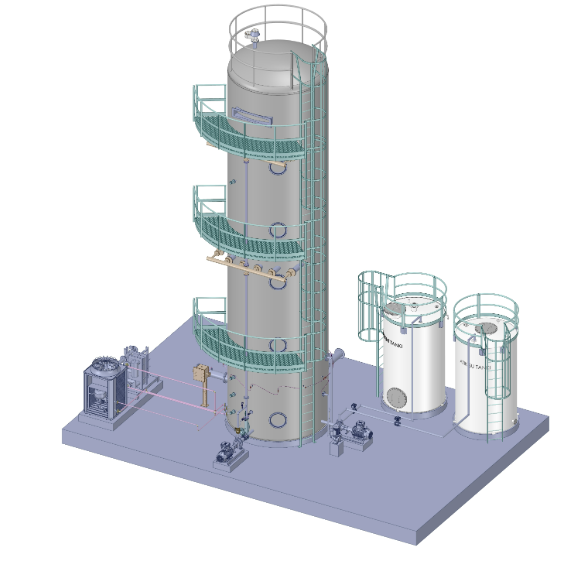

Main Equipment

- Scrubber tower

- Dosing and Nutrient Tank

- Spray nozzle and piping

- Rashing Ring

- PLC control panel

- Pump System

- Sensor and Transmitter

- Blower or Fan (change according to application area)

Our company is dedicated to designing and manufacturing scrubber units that meet the cleaning efficiency required for each customer's unique needs and processes.

Our team works to enhance the performance of each unit by ensuring that each product meets the highest standards of quality and reliability, taking into account the following specifications:Gas Flow rate (Nm3/h)

- Concentration and type of target compound

- Packing materials selection

- Type and size properties of packaging tower

- Nozzle Selection

- Microorganism Type

- Nutrients

- Oxygen Value

- pH and Temperature Value

Conclusion and Future Directions

The odor problem experienced in many industrial plants is solved with the help of bioscrubbers, which are environmentally friendly systems that do not use oxidizing chemicals. Highly efficient treatment processes are designed depending on the concentration and flow rate of the pollutant.

Currently, biological gas treatment accounts for only about 2% of the world waste gas treatment market. It is a more environmentally friendly biological method when used alone or in combination with adsorbers, which are physical methods. It is expected to realize a significant CAGR market growth of approximately 10% during the forecast period 2024-2032.

Learn more about our Bioscrubber: https://ergil.com/scrubber-systems/bio-scrubber/