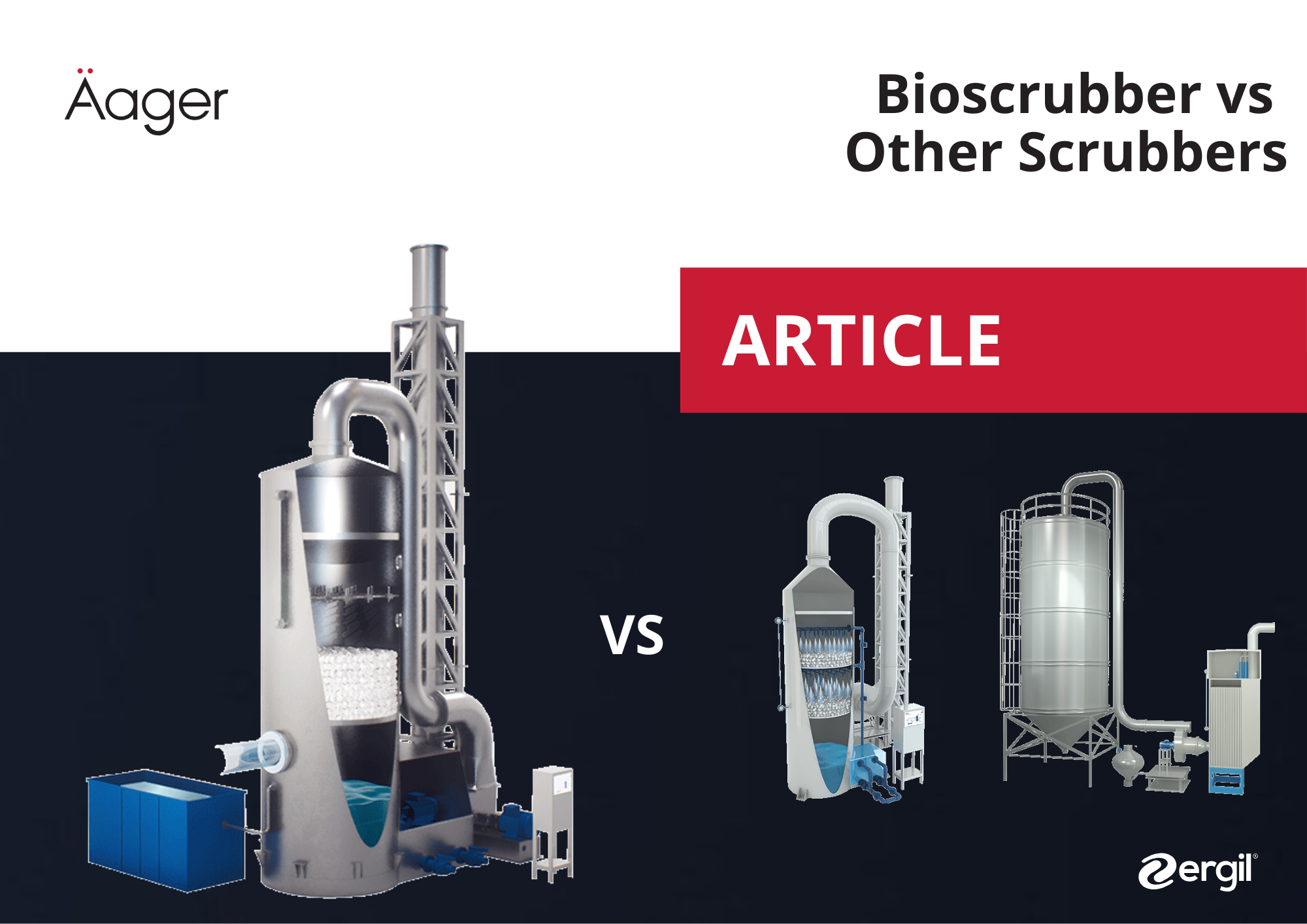

Comparison of Bioscrubber with other Scrubbers

Bioscrubber is designed to solve odor problems through biological activities that are specifically determined according to the odor component, without the use of chemical products. The main odor components of industrial plants and wastewater treatment plants odor problems are sulfur-containing organic compounds, and H2S, NH3 and amine derivatives, as well as VOCs.

Due to the high flow rate and high concentration, bioscrubber is generally recommended for plants that want to solve the odor problem at high efficiency without causing chemical waste.

However, there are a wide variety of odor cleaning systems currently available on the market. If these systems are categorized under main headings, they are divided into 3. However, considering the system requirements, they can also be used together.

- Wet Scrubber System

- Dry Scrubber- Adsorber System

- Biological Scrubber Systems

The advantages and disadvantage properties of these system can be investigated and compared according to given below parameters.

- Technical properties and odor identifications

- Efficiency of odor removal

- Capacities according to flow rate

When comparing operation and maintenance costs, each technology has advantages and disadvantages in its specific area of operational use.

Learn more about our Bioscrubber: https://ergil.com/scrubber-systems/bio-scrubber/

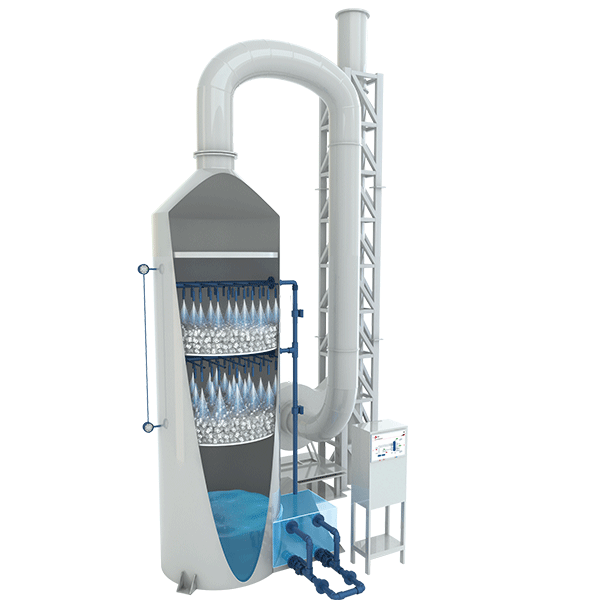

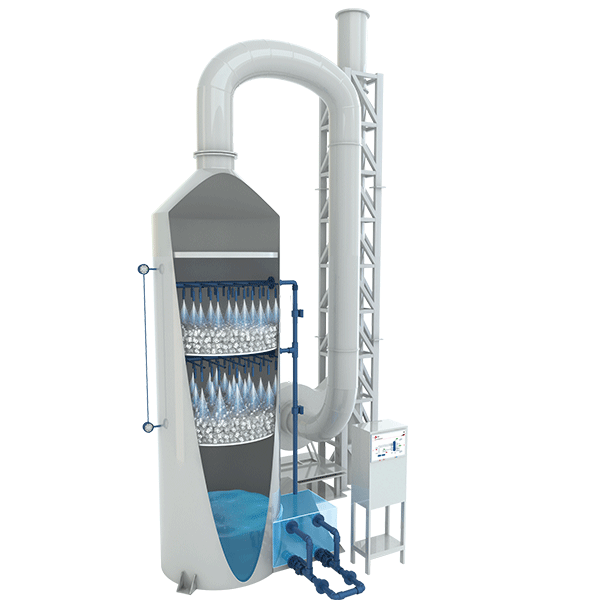

WET SCRUBBER

These scrubbers have been identified by different names depending on the scrubbing fluid used and the target contaminant. In general, caustic scrubber is classified as H2S scrubber, acidic scrubber, chemical scrubber.

In general, used for cleaning H2S/Sulfur compounds, NH3/amine compounds, SOx and NOx gases, VOCs, acidic gases, and Formaldehyde, etc.

But in basic principle, the system is based on the technique of physical and chemical absorption. Pollutants are eliminated by dissolving them in a liquid solution or capturing them by chemical reactions.

Commonly used chemicals,

- Sodium Hydroxide, NaOH,

- Sulfuric Acid, H2SO4,

- Phosphoric Acid, H3PO4,

- Sodium Hypochlorite, NaOCI,

- Soda- Lime

- Hydrogen Peroxide, H2O2

- And others,

The high surface area of the packings allows for mass transfer at high gas and liquid loads with low pressure drop. The packings can be used in random or regular configurations, depending on the application.

Scrubber system is controlled with pH, conductivity and density parameters according to system required.

The wet scrubber systems is a fast and effective gas cleaning method, especially used in situations where a chemical reaction is required. Bioscrubber offers a more sustainable solution for biodegradable pollutants.

Learn more about our Wet Packed Scrubber : https://ergil.com/scrubber-systems/wet-scrubber/

DRY SCRUBBER

Dry scrubber systems are used in many industrial plants to control air pollution. They remove acid gases, VOCs, heavy metals, and other harmful compounds from the air.

It is commonly known in the market as activated carbon-based scrubber or adsorber.

In this method, the odor-causing chemicals are passed through a tower containing various materials, such as activated carbon, filter, or molecular sieve. These materials physically or chemically adsorb the odors or chemical compounds.

In the adsorption system, physical adsorption can generally involve weak van der Waals bonds. One example of this is how VOCs stay on activated carbon. However, for gases like SO2 or H2S, a different process called chemisorption is used. This means that chemical bonds are used to clean the gases. For this, the surface of the activated carbon needs to be modified.

The adsorption principle is based on the highly porous structure of granular carbon. Adsorbents can be preferred as micro, meso, macro pore according to the system conditions.

In Thermal Power Plants, it is used for the removal of (SO₂) emission, which is an acidic gas resulting from the combustion of fossil fuels such as coal, oil or natural gas.

In The Metal Production and Iron- Steel Industries, it removes heavy metals, especially mercury (Hg) and nitrogen oxides.

In Waste Combustion Plants, emissions of harmful organic compounds such as dioxins and furans are controlled.

In the Food and Beverage Industry, compounds such as ethyl alcohol and acetaldehyde are removed during alcohol fermentation and during fruit processing.

Dry scrubber offers a faster and more practical solution for acidic gases and pollutants, but for VOCs and organic compounds bioscrubber systems may be more suitable. Bioscrubber provides biological advantages in the removal of organic compounds.

Learn more about our Dry Scrubber : https://ergil.com/scrubber-systems/dry-scrubber/

BIOFILTER and BIOTRICKLING

Over the years, three primary bioreactor designs have emerged: the biological filter, the biological scrubber, and the biological trickling filter. Each type can be distinguished from the others by the use of a carrier material and a mobile liquid phase, respectively.

In general, the biofiltration process is typically designed for the removal of water-soluble substances. General mechanism of biofiltration is similar for all given bioreactor type but application areas and show different properties. In the biofilter system, the contaminated gas is humidified in separate chamber before feeding into the biofilter.

The contaminated gas then undergoes biodegradation in a biofilm layer that forms a “film” on the packaging materials.

Biofilter is needed a larger area than bioscrubber, because of the gas needs to diffuse through the backfill bed. In biofilters, drying of the biofilm reduces cleaning efficiency, so humidity control is more important. Also, the biofilter is sensitive to dust and particles in the media, which can clog the biofilter

A biotrickling filter is a combination of a biofilter and a bioscrubber. The bacteria responsible for decomposition are inactivated on a carrier or filter material. The filter material is made up of synthetic foam, lava or a structured plastic filler. The surface must have a composition that allows the biomass to bind to it effectively. In a biotrickling filter, the backfill can become clogged due to strong growth in biofilm. This will lead to preferential flows, which will reduce efficiency and increase pressure drop.

Compared to bioscrubber, biotrickling filter is generally effective in cleaning acidic gases while bioscrubber have more gas options to be cleaned. The drying of the filter it includes, the decrease in pH due to acidic gases may reduce the cleaning efficiency.