ERGIL Scrubber Skid Systems

Product Description

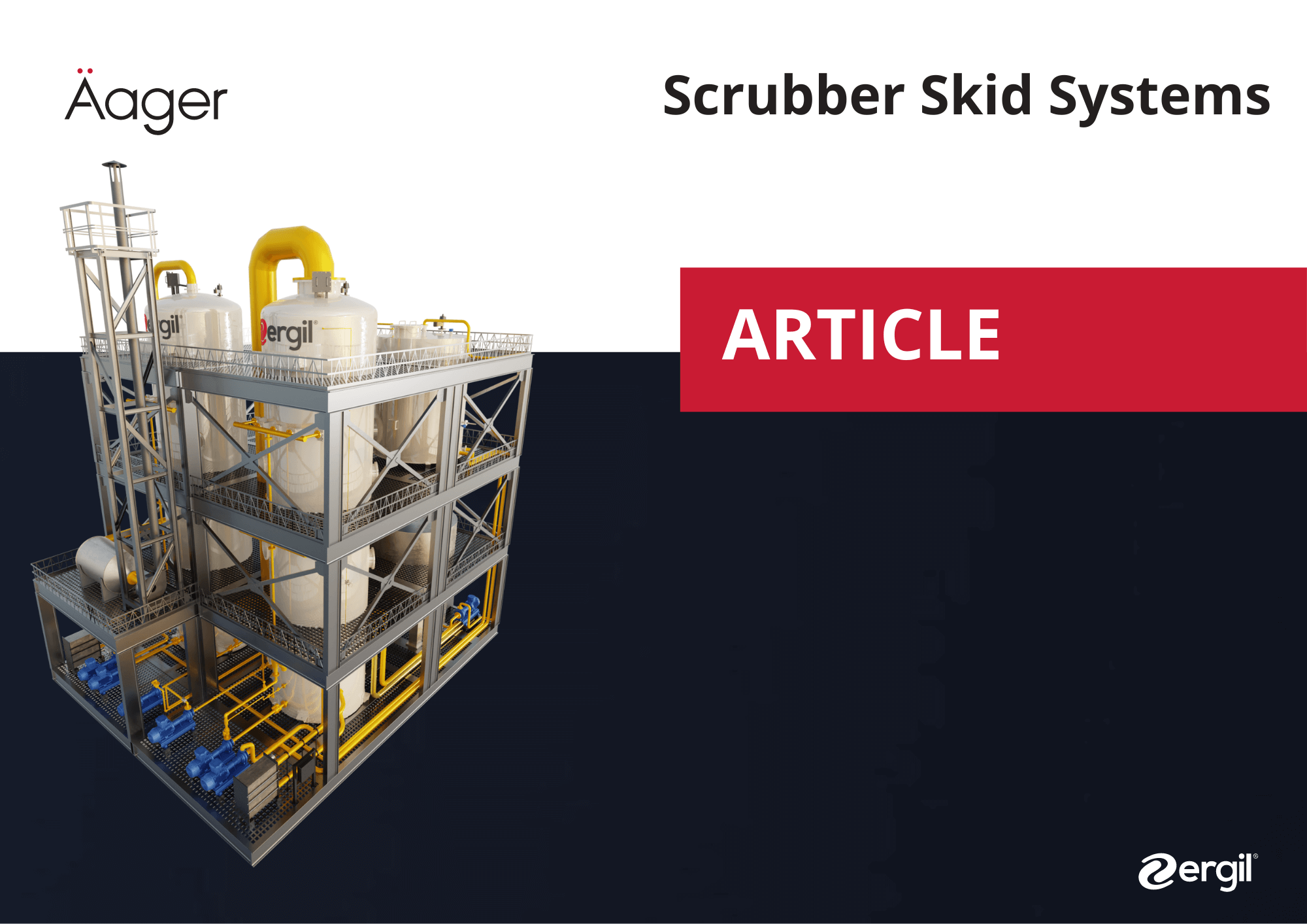

ERGIL Scrubber Skid Systems are advanced engineering solutions designed to efficiently remove pollutants from industrial gas streams. These systems are integral to maintaining compliance with environmental regulations and ensuring safe and clean operations in various industries. ERGIL's scrubber skids are engineered to handle a wide range of contaminants, including particulates, sulfur oxides (SOx), nitrogen oxides (NOx), hydrogen sulfide (H₂S), and volatile organic compounds (VOCs).

Design Features

High Efficiency: ERGIL scrubber skids are designed to achieve high removal efficiencies, ensuring that harmful pollutants are effectively captured and neutralized. This is achieved through a combination of optimized gas-liquid contact, precise control systems, and robust construction materials.

Custom Engineering: Each system is custom-engineered to meet the specific needs of the application. This includes selecting the appropriate scrubber technology (e.g., wet, dry, or semi-dry) and designing the system to handle the expected gas flow rates and pollutant concentrations. Detailed Computational Fluid Dynamics (CFD) simulations and Finite Element Analysis (FEA) are conducted to ensure optimal performance and structural integrity.

Material Selection: Depending on the process requirements, scrubber skids can be constructed from a variety of materials, including stainless steel, carbon steel, and specialty alloys such as Hastelloy or Inconel. Material selection is based on corrosion resistance, temperature tolerance, and compatibility with the process gases. Advanced surface treatments and coatings can be applied to enhance durability.

Control Systems: Advanced control systems are integrated into the skid units to provide precise control over process parameters. This includes automated monitoring and adjustment of key variables such as pH, flow rates, and temperature to optimize performance. Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS) are utilized for seamless integration with plant-wide control systems. Real-time data acquisition and remote monitoring capabilities are also available for enhanced operational oversight.

Compact Design: ERGIL scrubber skids are designed to maximize space efficiency, making them ideal for installations with limited space. The compact design also facilitates easier transportation and installation. Modular designs allow for scalability and easy integration with existing systems.

Key Benefits

Cost Savings: Pre-fabrication and off-site testing reduce field labor costs and minimize onsite construction time, leading to significant cost savings. Factory Acceptance Testing (FAT) ensures that systems are fully operational before delivery, reducing commissioning time.

Quality Control: Manufacturing in a controlled environment ensures that all system components meet high-quality standards, resulting in reliable and consistent performance. Non-Destructive Testing (NDT) methods such as radiography, ultrasonic testing, and hydrostatic testing are employed to verify the integrity of welds and materials.

Flexibility: Scrubber skids can be customized to meet specific process requirements and easily scaled by adding additional units. This flexibility makes them suitable for a wide range of applications, from small-scale operations to large industrial complexes.

Reduced Downtime: Pre-tested skid systems require less time to become operational once delivered to the site, reducing overall downtime. This ensures continuous operation and minimizes disruption to the production process.

Compliance: ERGIL scrubber skids help facilities comply with stringent environmental regulations by effectively controlling emissions and reducing pollutant levels. Compliance with international standards such as ASME, ANSI, API, and ISO ensures that systems meet the highest quality and safety requirements.

How to Select a Scrubber Skid System

- Identify the Contaminants: Determine the types and concentrations of pollutants that need to be removed from the gas stream. This involves detailed analysis of the gas composition and process conditions.

- Choose the Scrubber Type: Select the appropriate scrubber technology (wet, dry, or semi-dry) based on the nature of the contaminants and the process requirements. Wet scrubbers are typically used for acidic gases, while dry scrubbers are suitable for particulate removal.

- Determine the Gas Flow Rate: Calculate the expected gas flow rates to ensure the scrubber system is adequately sized. This involves detailed flow rate calculations and consideration of process variations.

- Material Compatibility: Choose materials that are compatible with the process gases and the operating environment. This includes considerations for corrosion resistance, temperature tolerance, and mechanical strength.

- Control Systems: Specify the required control systems and automation features to optimize performance and ensure safe operation. This includes selecting appropriate sensors, controllers, and data acquisition systems.

- Custom Engineering: Work with ERGIL’s engineering team to design a system that meets your specific needs, including space constraints, environmental conditions, and integration with existing processes. Detailed engineering drawings, P&IDs, and 3D models are provided to ensure accurate implementation.

Configurations

- Vertical Scrubber Skids: Ideal for installations with limited floor space. These systems offer high removal efficiencies and are suitable for a wide range of applications. Vertical designs facilitate gravity separation and are often used for gas streams with high particulate loads.

- Horizontal Scrubber Skids: Provide a larger surface area for gas-liquid contact, making them suitable for high flow rates and applications with significant particulate loads. Horizontal designs allow for easy maintenance and access to internal components.

- Modular Designs: ERGIL offers modular scrubber skid designs that can be easily expanded or reconfigured to meet changing process needs. Modular designs enable phased implementation and future scalability.

Applications

- Oil and Gas: Removal of hydrogen sulfide (H₂S) and other contaminants from natural gas streams. Scrubber skids ensure compliance with environmental regulations and enhance safety in gas processing facilities.

- Chemical Processing: Control of volatile organic compounds (VOCs) and other hazardous air pollutants. Scrubber skids provide effective emission control in chemical plants, ensuring compliance with air quality standards.

- Water Treatment: Odor control and removal of harmful gases from wastewater treatment plants. Scrubber skids improve air quality and safety in treatment facilities.

- Pharmaceuticals: Ensuring clean air in production facilities by removing hazardous fumes and gases. Scrubber skids maintain high standards of hygiene and safety in pharmaceutical manufacturing.

- Food and Beverage: Maintaining air quality by removing odors and contaminants from processing areas. Scrubber skids ensure safe and clean environments in food and beverage production.

ERGIL Scrubber Skid Systems provide a versatile, efficient, and cost-effective solution for a wide range of industrial applications. With their custom engineering, high efficiency, and advanced control systems, these skid systems are designed to meet the most stringent environmental regulations while ensuring reliable and consistent performance. Whether you need to remove particulates, sulfur oxides, nitrogen oxides, or other contaminants, ERGIL’s scrubber skids offer the ideal solution to keep your operations clean and compliant.