Istanbul, November 22, 2023 — ERGIL leading process and static equipment manufacture successfully completed Storage Tank Project for The Akkuyu Nuclear Power Plant in Mersin, Türkiye.

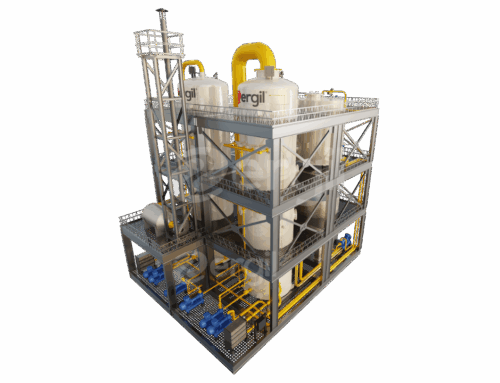

ERGIL successfully completed design, engineering and prefabrication of 6 quantity 14 meter diameter storage tank project for Türkiye’s one and only nuclear plant, marking a significant milestone in advancing Türkiye’s nuclear energy infrastructure.

The completion of the 6 quantity 14-meter diameter storage tank project demonstrates ERGIL’s commitment to excellence and precision in the fabrication of critical infrastructure components. These storage tanks, designed in accordance with the stringent standards of API 650, reflect ERGIL’s dedication to ensuring the highest quality and safety measures in the nuclear plant environment.

Recognizing the unique challenges posed by the nuclear environment, ERGIL meticulously designed the storage tanks, taking into consideration the specific conditions and requirements of The Akkuyu Nuclear Power Plant. The adherence to API 650 standards underscores ERGIL’s commitment to maintaining the highest industry benchmarks for the project. ERGIL’s Storage Tank Project goes beyond conventional design by addressing critical aspects of environmental resilience. The storage tanks are strategically designed to collect drain water, mitigating the risk of potential floods, and efficiently gather excess rainwater. These tanks play a vital role in fortifying the overall infrastructure of The Akkuyu Nuclear Power Plant.

Critical Equipment for Seismic Resilience:

Condensate storage tanks (CSTs) are classified as critical equipment within nuclear power plants, capable of withstanding strong shaking during a design basis earthquake to ensure the provision of subsequent cooling water. ERGIL’s structural modeling and dynamic analysis of CSTs, considering fluid-structure interaction (FSI) and coupling issues, are a testament to the company’s commitment to safety and excellence.

2D and 3D Modeling for Seismic Response:

ERGIL’s engineers conducted comprehensive modal analyses and time history analyses using both 2D and 3D models. This investigation aimed to predict the dynamic behavior of CSTs under varying ground motion intensities. While 2D simplified models offer a quick assessment of dynamic response when there is sufficient margin to failure, a detailed 3D model is imperative for examining limit states associated with potential tank failure.

Mr.Daniil Bezborodov, Technical Sales Specialist in nuclear division at ERGIL, expressed enthusiasm about the successful completion of the Storage Tank Project, stating, «We are proud to have contributed to Türkiye’s nuclear energy infrastructure through the successful delivery of the Akkuyu Nuclear Power Plant Storage Tank Project. ERGIL’s commitment to quality, safety, and innovation is evident in every aspect of this endeavor.»

ERGIL looks forward to continued collaboration with Türkiye’s energy sector, aiming to play a crucial role in shaping the future of the country’s energy landscape. The successful completion of The Akkuyu Nuclear Power Plant Storage Tank Project reinforces ERGIL’s position as a key player in providing state-of-the-art solutions for critical infrastructure projects.

ABOUT US

ERGIL is a full fletched engineering and fabrication company that is focused on critical high pressure static equipment; such as pressure vessels, heat exchangers, and specialized storage tanks and process equipment; wet packed scrubbers, absorbers, separators, filters, pig launcher & receivers, surge vessels and silencers. ERGIL currently operates in one of a kind 32,000 sq/m manufacturing facility in Mersin, Turkey, which enhances its advanced manufacturing capabilities and services.

ERGIL is ISO 9001, 14001, OHSAS 18001, ASME U-4, S-2, R Stamp accredited and has CE/ ATEX certificates for its storage tank products. Storagetech ™ is specialized in designing, manufacturing and developing storage tank safety and emission control equipment; such as aluminum dome & floating roof, external floating roof seals, and drain, flame arrestors, pressure vacuum valves, floating suction system, odor control, dryers, and CO2 absorbers.

ERGIL has developed an excellent reputation internationally in the industry due to its total commitment to quality in every aspect of the business. Beginning with raw materials through process production and delivery, ERGIL has always insisted on the highest possible quality associated with the product lines.

For further information, please visit www.ergil.com or feel free to message me. I will be pleased to offer support and answer any questions you may have.