The effect of microorganism on bioscrubber

Designed to use the biological mechanism, bioscrubber are employed in the world of gaseous pollution removal. Sulfur compounds, in particular hydrogen sulfide (H₂S), ammonia (NH₃) and volatile organic compounds (VOCs) are especially effective.

Bioscrubber works by passing the contaminated gas streams through a liquid medium (generally, water or special washing solution) with which microorganisms reside and biodegrade the contaminants. In bioscrubber systems, the bacteria represent the primary biological purification agent.

MICROORGANISM

In the biodegradation of pollutants, bacteria are involved. Through biochemical processes, these bacteria degrade the pollutants brought to the water by the gas stream in the bioscrubber and transform them into less or completely harmless compounds. The microorganisms used for this purpose are selected based on the pollutant type.

TYPE of SPECIFIC MICROORGANISM

- Sulfur-Oxidizing Bacteria (for sulfur compounds)

The biological removal of sulfides is best accomplished with Thiobacillus, Sulfolobus, and other known colorless sulfur bacteria. These are some of the sulfur-oxidizing bacteria which are the best suited from a technological perspective. They are especially adequate because of their high rate of sulfide oxidation and their very weak nutritional bars as well as their very high affinity for oxygen and sulfides. These bacteria outperform chemical treatment of sulfides in bioreactors with low oxygen and in the natural environment. The reaction mechanism of sulfur-oxidizing bacteria works by converting H₂S to sulfate (SO₄²-).

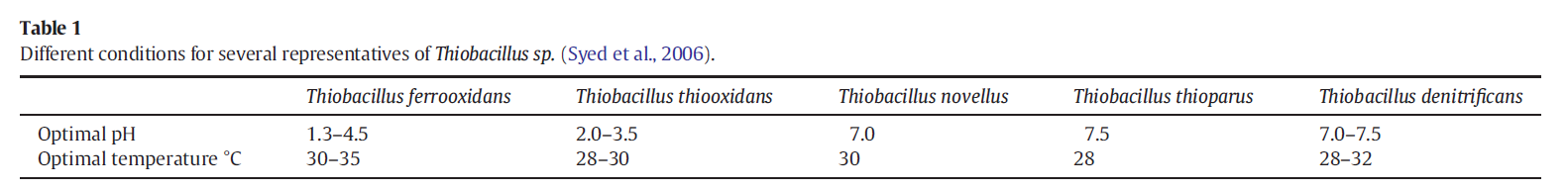

The most prevalent and extensively studied genus is Thiobacillus sp. Many species are acidophilic, with an optimum pH range of 1-6. However,

some species are also capable of functioning in alkaline environments.

Different species of sulfur-oxidizing bacteria also have different temperature ranges. While most are mesophilic or thermophilic, a few bacteria, such as Thermothrix azorensis, perform at temperatures as high as 76 °C to 86 °C.

- Nitrification and Denitrification Bacteria

Nitrification is essential in the removal of ammonia in bioscrubber systems.

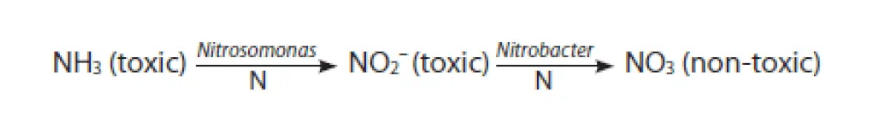

It involves the biological converting (oxidation) of ammonia (NH₃) to nitrite (NO₂) and afterward into nitrate (NO₃) in two aerobic processes. Nitrification is done by two different groups of bacteria known as ammonia-oxidizing bacteria and nitrite-oxidizing bacteria

which is Nitrosomonas and Nitrobacter species purify ammonia by oxidizing it to nitrite and nitrate.

Amines are the primary cause of odors in composting facilities, wastewater treatment plants and landfills, and animal farms. Especially the bacterial families Pacoccus ve Arthrobacter are used for decomposition of trimethylamine, dimethylamine, and methylamine. Typically, these species convert nitrite and nitrate to N2 gas by denitrification in environments where oxygen levels are limited.

- Volatile Organic Compounds (VOC) Removal:

Depending on their chemical structure, volatile organic compounds (VOCs) can be removed by certain types of bacteria. VOCs, which include ethanol, methanol, acetone, methyl ethyl ketone, and methyl isobutyl ketone, can be effectively treated using biological scrubbers. These scrubbers utilize micro-organisms such as Pseudomonas, Bacillus, and Arthrobacter, which are capable of converting carbon-based organic pollutants into harmless by-products like CO₂ and H₂O.

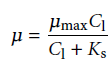

The growth rate usually depends on factors such as pH, temperature, ionic charge, presence of toxic compounds, and substrate concentration. Understanding the microbial growth rate is important for the system because it is an important parameter in determining the biomass retention time and specific substrate conversion rate. The relationship between growth and substrate

where μ is the specific growth rate (h−1), μmax the maximum specific growth rate (h−1), Ks the Monod constant (gm−3), and Cl the substrate concentration (gm−3).

In order for biological scrubbers to perform at their best, it is very important to keep these bacteria in suitable conditions. These conditions are based on factors such as temperature, pH, nutrients, oxygen, and humidity. Typically, bacteria are commonly contained in a liquid phase within the system to support bacterial activity and uptake of nutrients and energy sources.

BIOPROCESS CONTROL in BIOSCRUBBERS

- Temperature and pH

Temperature and pH should be optimized according to the type of bacteria selected.

- Oxygen

A minimum dissolved oxygen concentration of 1-2 mg. L-1 is recommended for optimal biological activity.

- Humidity

The moisture content of the filter bed is a critical factor in biological scrubber performance. The moisture content required by microorganisms to meet their basic requirements is approximately 20% to 60% by weight. Moisture levels below the optimum can cause the bed to dry out, while excess water can cause malodorous emissions due to a lack of oxygen.

- Nutrients

A nutrient solution must be added to the water phase to sustain microbial biodegradation activity. Microbes generally need macronutrients (C, H, O, N, P, and S) and micronutrients (vitamins and metals) to grow and metabolize. Therefore, KH2PO4, KNO3, (NH4)2SO4, NH4Cl, FeSO4, etc. can be added to the water phase.

CONCLUSION

Biological scrubbers are classified as environmentally friendly systems that do not use oxidizing chemicals. Bioscrubber uses microbial processes to convert harmful pollutants into lower-hazard forms or stable byproducts.

The use of bacteria in bioscrubbers is an effective and sustainable strategy for air pollution control, especially for the removal of compounds such as hydrogen sulfide (H2S), ammonia (NH3), volatile organic compounds (VOCs).

Learn more about our Bioscrubber: https://ergil.com/scrubber-systems/bio-scrubber/