Comprehensive Guide to Process Piping and Skid Systems by ERGIL

Introduction to ERGIL and Skid Systems

With over 40 years of industry expertise, ERGIL stands as a leading provider of process piping and skid systems, delivering unparalleled engineering and manufacturing solutions. Our dedication to quality and innovation has positioned us as a trusted partner for clients in the oil, gas, petrochemical, and water treatment industries. This guide aims to provide a comprehensive overview of skid systems, highlighting their design, applications, safety considerations, and the advantages they bring to industrial operations.

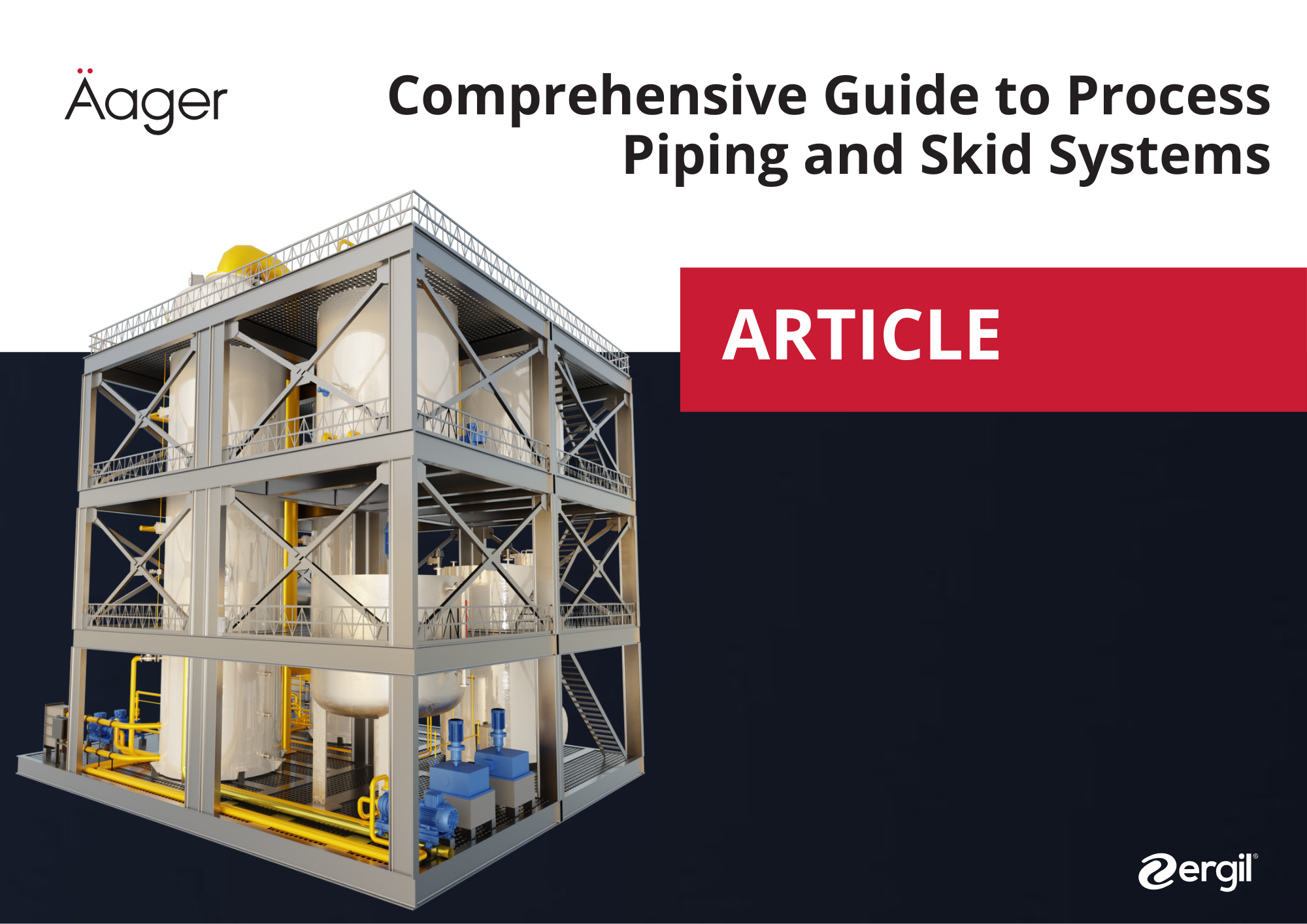

Understanding Skid Systems

A skid system, often referred to as a "skid-mounted system," is a pre-assembled, self-contained process unit mounted on a steel frame or "skid." These systems are engineered for easy transportation, installation, and integration into larger processes. Skid systems are commonly used in various industries, including oil and gas, chemical processing, water treatment, pharmaceuticals, and food and beverage production.

Design and Engineering of Skid Systems

Modular Design:

Skid systems are designed with modularity in mind, allowing for the combination of multiple skids to form a complete processing system. This modular approach provides flexibility and scalability, enabling easy system expansion or reconfiguration. Each module can be individually optimized and then integrated seamlessly, ensuring that the overall system performs at peak efficiency.

Pre-assembly and Testing:

At ERGIL, we pre-assemble and rigorously test our skid systems in a controlled environment. This ensures that each system meets the highest standards of quality and performance before being shipped to the installation site. Pre-assembly reduces on-site construction time and minimizes the risk of installation errors. Our state-of-the-art testing facilities allow us to simulate actual operating conditions, ensuring that each skid system functions as intended under all scenarios.

Compact and Space-efficient:

Skid systems are engineered to maximize space efficiency, fitting into tight spaces and allowing for easy transport. This compact design is particularly beneficial for offshore platforms and remote locations where space is limited. The design process involves detailed 3D modeling and spatial analysis to ensure that all components fit perfectly within the allocated space without compromising accessibility or maintainability.

Integration of Components:

ERGIL's skid systems are equipped with all necessary components, including pumps, valves, piping, instrumentation, and control systems. These components are integrated into a single frame, ensuring seamless operation and ease of maintenance. The integration process includes the use of advanced control systems and instrumentation to monitor and control all aspects of the process, ensuring optimal performance and safety.

Applications of Skid Systems

Oil and Gas

- Chemical Injection Skids: These skids inject precise amounts of chemicals into the production stream to optimize oil and gas recovery and protect equipment from corrosion. They are equipped with advanced metering pumps, corrosion inhibitors, and control systems to ensure accurate dosing and real-time monitoring.

- Metering Skids: Used for accurate measurement of hydrocarbons, ensuring compliance with industry standards and regulatory requirements. These skids include flow meters, control valves, and data acquisition systems to provide real-time flow measurement and reporting.

- Gas Processing Units: These units separate and process natural gas, removing impurities and preparing it for transportation and sale. They include components such as scrubbers, dehydrators, and separators to ensure that the gas meets the required specifications.

Water Treatment:

- Filtration Skids: These systems filter impurities from water, ensuring safe and clean water supply for industrial and municipal applications. They include multi-stage filtration systems, automatic backwashing, and advanced control systems for continuous monitoring and maintenance.

- Reverse Osmosis Systems: Used for desalination and purification, providing high-quality water for various industrial processes. These skids include high-pressure pumps, membrane modules, and energy recovery devices to optimize efficiency and reduce operational costs.

- Chemical Dosing Units: These units accurately dose chemicals into the water treatment process to achieve desired water quality parameters. They include precision metering pumps, chemical storage tanks, and control systems for accurate dosing and monitoring.

Chemical Processing:

- Reactor Skids: These skids house chemical reactors and associated equipment, enabling controlled chemical reactions for product synthesis. They include reactors, heat exchangers, and control systems to ensure precise temperature and pressure control.

- Mixing Systems: Designed for the homogeneous mixing of chemicals, ensuring consistent product quality. These skids include agitators, mixing tanks, and control systems to optimize mixing efficiency and product uniformity.

- Separation Units: These units separate chemical mixtures into their constituent components, improving process efficiency. They include distillation columns, separators, and control systems to ensure accurate separation and product purity.

Pharmaceuticals:

- Clean-in-Place (CIP) Systems: Automated cleaning systems that ensure sanitary conditions in pharmaceutical manufacturing. These skids include cleaning solution tanks, pumps, and control systems to ensure thorough and efficient cleaning of all process equipment.

- Formulation Skids: These skids handle the precise mixing and formulation of pharmaceutical products. They include mixing vessels, dosing pumps, and control systems to ensure accurate formulation and consistent product quality.

- Bioreactor Systems: Used for the cultivation of microorganisms and cells, essential for the production of biopharmaceuticals. These skids include bioreactors, control systems, and monitoring equipment to ensure optimal growth conditions and product yield.

Food and Beverage:

- Pasteurization Units: These units pasteurize liquids to eliminate harmful microorganisms while preserving product quality. They include heat exchangers, control systems, and monitoring equipment to ensure precise temperature control and product safety.

- Blending Skids: Designed for the accurate blending of ingredients in food and beverage production. They include mixing tanks, agitators, and control systems to ensure consistent product quality and uniformity.

- Beverage Processing Systems: Complete systems for the processing and packaging of beverages, ensuring product safety and consistency. They include filtration systems, filling machines, and control systems to optimize production efficiency and product quality.

Safety Considerations in Skid Systems

Safety is a paramount concern in the design and operation of skid systems. ERGIL incorporates several safety features and best practices to ensure the safe operation of our skid systems:

Pressure Relief Devices:

Skid systems are equipped with pressure relief valves and rupture discs to prevent overpressure situations, protecting both personnel and equipment. These devices are designed to activate automatically when pressure exceeds safe levels, releasing excess pressure to prevent equipment damage and ensure safety.

Instrumentation and Controls:

Advanced instrumentation and control systems monitor process parameters in real-time, providing early warning of potential issues and enabling prompt corrective action. These systems include sensors, transmitters, and control valves that provide continuous monitoring and control of pressure, temperature, flow, and other critical parameters.

Emergency Shutdown Systems:

Automated emergency shutdown systems (ESD) are integrated into skid systems to quickly and safely shut down operations in the event of a hazardous situation. These systems include safety relays, emergency stop buttons, and interlocks that ensure a rapid and safe shutdown of the system in case of emergency.

Hazardous Area Classification:

Skid systems are designed and certified for use in hazardous areas, ensuring compliance with international safety standards such as ATEX and IECEx. This includes the use of explosion-proof equipment, intrinsically safe devices, and proper grounding and bonding to prevent ignition sources.

Material Selection:

Materials used in skid systems are carefully selected for their chemical compatibility, mechanical strength, and resistance to corrosion, ensuring long-term reliability and safety. This includes the use of stainless steel, high-alloy materials, and corrosion-resistant coatings to withstand harsh operating conditions.

Advantages of Skid Systems

Cost Savings:

Pre-fabrication and testing in a controlled environment reduce field labor costs and minimize onsite construction time. This results in significant cost savings and improved project timelines. Pre-fabrication also allows for better quality control and reduces the risk of rework and delays due to onsite issues.

Quality Control:

Manufacturing in a controlled environment ensures high quality and reliability of system components. ERGIL’s stringent quality control procedures guarantee that each skid system meets the highest standards. This includes non-destructive testing (NDT), hydrostatic testing, and material certification to ensure the integrity and performance of all components.

Flexibility and Scalability:

Skid systems can be customized to meet specific process requirements and easily scaled by adding more skids. This flexibility allows for future expansion and adaptation to changing process needs. Skid systems can be designed for modular integration, allowing for easy addition or removal of units to accommodate changes in production capacity or process requirements.

Reduced Downtime:

Since skid systems are pre-tested, they typically require less time to get up and running once delivered to the site. This reduces downtime and ensures a smooth startup. Pre-testing also allows for the identification and resolution of any issues before the system is installed, further reducing the risk of delays and operational disruptions.

Mobility:

Skid systems can be relocated if necessary, providing flexibility for temporary installations or future plant modifications. This mobility is particularly advantageous for remote and offshore installations. Skid systems can be easily disassembled, transported, and reassembled at a new location, providing flexibility and adaptability for changing operational needs.

ERGIL’s Skid System Manufacturing Capabilities

ERGIL’s state-of-the-art manufacturing facility spans 40,000 square meters and is equipped with advanced fabrication and testing equipment. Our capabilities include:

Welding and Fabrication:

Our facility features automated welding systems, CNC machining, and advanced fabrication tools, ensuring precision and consistency in every project. We use advanced welding techniques such as TIG, MIG, and orbital welding to ensure high-quality welds that meet stringent industry standards.

Quality Assurance:

ERGIL is ISO 9001, 14001, OHSAS 18001, and ASME U Stamp certified. Our rigorous quality assurance processes include non-destructive testing (NDT), hydrostatic testing, and material certification. We employ advanced testing methods such as radiographic testing, ultrasonic testing, and dye penetrant testing to ensure the integrity and performance of all components.

Engineering Excellence:

Our team of experienced engineers utilizes the latest design software and methodologies to create innovative and efficient skid systems. We collaborate closely with clients to ensure that our designs meet their specific needs and regulatory requirements. Our engineering capabilities include computational fluid dynamics (CFD) analysis, finite element analysis (FEA), and 3D modeling to optimize the design and performance of our skid systems.

Sustainability:

ERGIL is committed to sustainability and environmental protection. Our skid systems are designed to minimize environmental impact, with features such as energy-efficient components and low-emission operation. We use environmentally friendly materials and manufacturing processes, and our systems are designed to reduce waste and emissions, contributing to a cleaner and more sustainable environment.

Customer Support:

We provide comprehensive support throughout the project lifecycle, from initial consultation and design through to installation, commissioning, and maintenance. Our global network ensures that we can support clients wherever they are located. We offer training programs, technical support, and after-sales services to ensure that our clients receive the best possible support and achieve optimal performance from their skid systems.

ERGIL’s expertise in process piping and skid systems offers unmatched solutions for a wide range of industrial applications. Our commitment to quality, safety, and innovation ensures that our clients receive the best possible products and services. Whether you are looking for a turnkey solution or a custom-engineered skid system, ERGIL has the experience and capability to meet your needs. Contact us today to learn more about how we can support your projects and help you achieve operational excellence.