The Importance of Hydrogen Storage

Hydrogen storage is a crucial technology for enabling the wider use of hydrogen and fuel cell systems across applications such as stationary power generation, portable energy devices, and transportation. Although hydrogen contains the highest energy per unit mass of any fuel, its low density at ambient conditions limits the energy available per unit volume. Therefore, developing advanced storage solutions with higher volumetric energy density is essential for practical and efficient hydrogen utilization.

Type I Cylinders and Bundle Systems

Hydrogen (H₂) is the lightest and most abundant element in the universe. With a high energy density of approximately 120 MJ/kg, hydrogen serves as an ideal energy carrier. When used in fuel cells, it produces only water vapor, delivering zero carbon emissions. Its applications are rapidly expanding across various sectors, from industrial production and energy to mobility solutions, as well as food and medical technologies.

Effective and safe hydrogen storage is critical for unlocking its full potential and enhancing energy efficiency. High-pressure gas storage, particularly using Type I cylinders and modular bundle systems, offers one of the most reliable and flexible solutions for both industrial and mobile applications.

Types of Hydrogen Storage Hydrogen Methods

- Pressurized Gas Storage: Hydrogen is stored in cylinders or tanks under high pressure in its gaseous form. This method enables rapid filling and discharge, is easily scalable to meet varying capacity needs, and offers excellent portability for both stationary and mobile applications.

- Cryogenic Liquid Storage: Hydrogen is liquefied at -253°C for storage. While this method provides very high energy density, it requires specialized low-temperature management and advanced insulation systems to maintain efficiency and safety.

- Solid or Chemical Storage: Hydrogen is stored within metal hydrides or chemical compounds. This approach offers safe, low-pressure storage, but the rates of filling and discharging are inherently limited compared to gaseous storage.

Today, pressurized gas storage is the preferred solution for industrial applications and hydrogen fueling stations due to its flexibility, fast filling capabilities, and modular design, making it ideal for scalable and reliable hydrogen supply systems.

Type I Steel Hydrogen Cylinders

Type I cylinders are manufactured entirely from high-strength steel, ensuring maximum safety and durability for high-pressure hydrogen storage. These cylinders:

- Withstand working pressures up to 200 bar

- Are highly durable and resistant to mechanical fatigue

- Enable easy integration with standard connection interfaces

Advantages:

- Compact storage with high-pressure capacity

- Long-term safety and durability

- Portability and ease of use due to robust yet optimized steel construction

- Low cost, simple construction, well-established manufacturing techniques

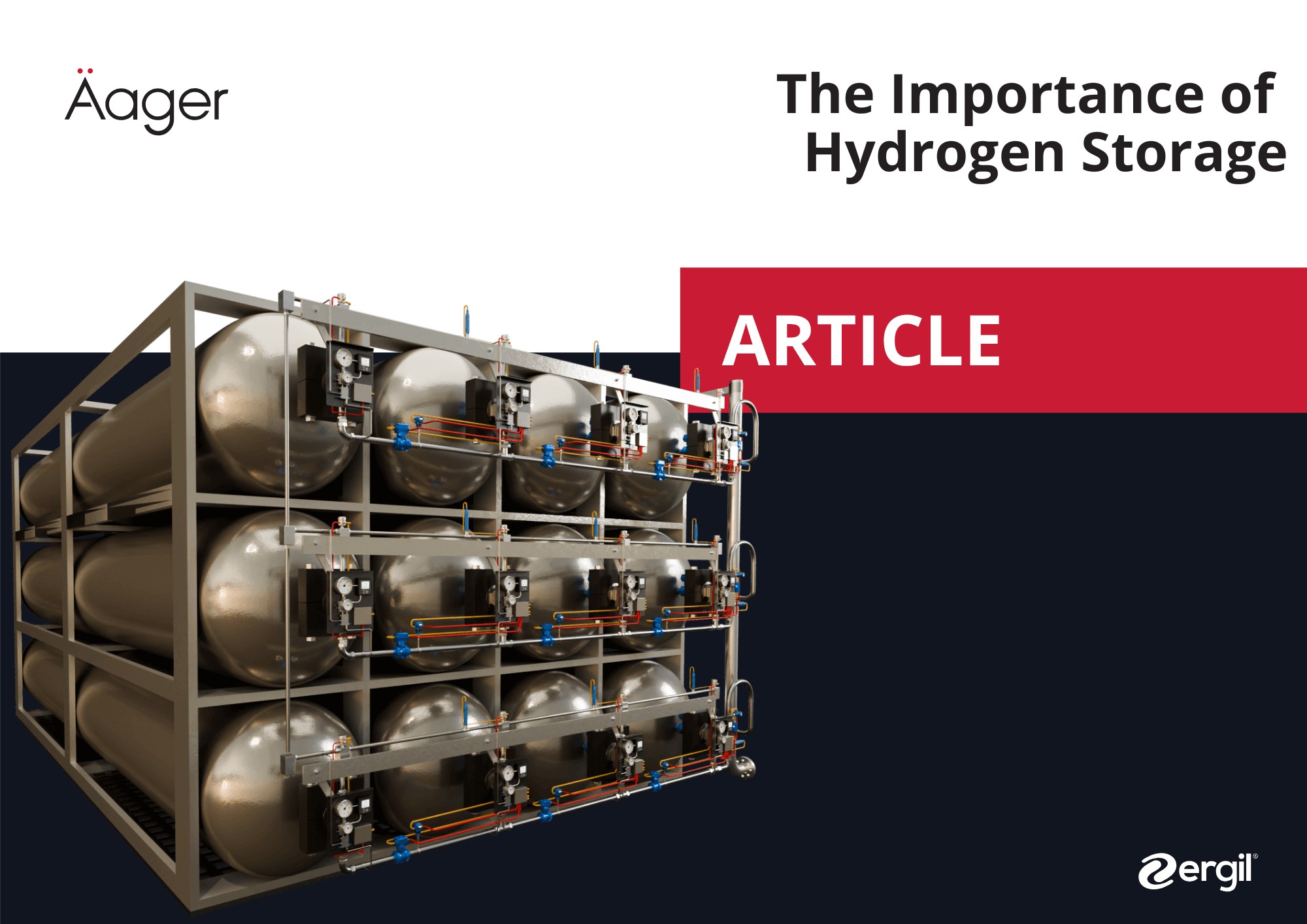

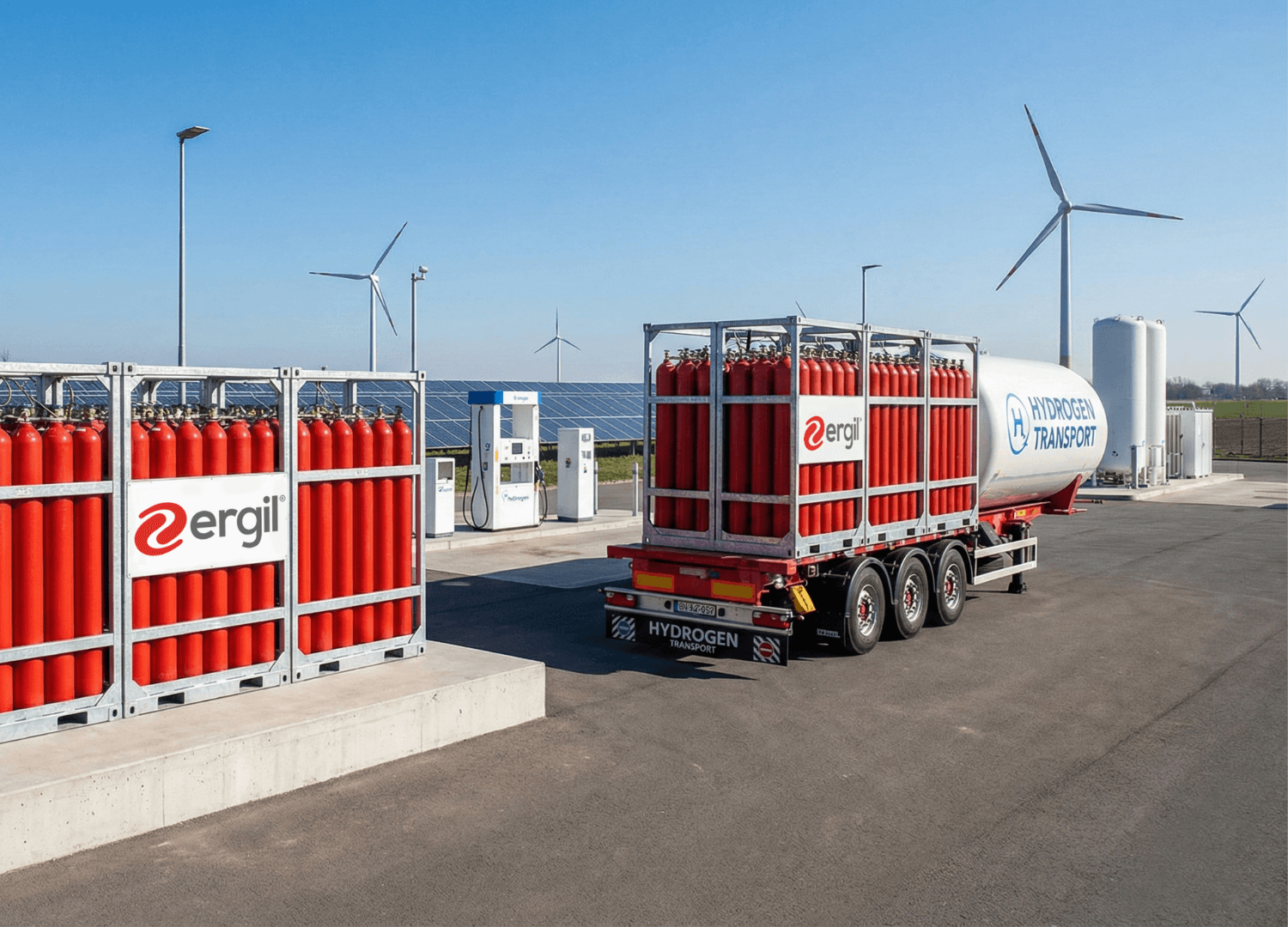

Bundle Systems

The bundle system is a modular storage solution in which multiple Type I cylinders are connected in parallel. These systems provide high-volume hydrogen storage capacity and offer the following advantages:

- Modular Design: Storage capacity can be easily increased or decreased as needed.

- Continuous Gas Supply: An integrated manifold system ensures equal pressure and consistent gas distribution from all cylinders.

- Compact and Efficient: Enables management of large-volume storage solutions in smaller spaces.

- Advanced Monitoring: Pressure, temperature, and safety parameters are continuously monitored, minimizing potential risks.

Application Areas

- Industrial Use: Hydrogen production and storage facilities, filling stations, research laboratories

- Energy Sector: Fuel cell power plants, renewable energy storage, microgrid solutions

- Mobility Solutions: Hydrogen-powered buses, trucks, and fleet vehicles

- Medical and Food Technologies: Controlled hydrogen use in the medical gas and food industries

Technical Specifications

Single Type I Cylinder:

- Material: High-strength steel or aluminum

- Maximum working pressure: 35-40-50-70-100-150-200 bar (Customizable for customers)

- Volume/weight optimization

Bundle System:

- Modular assembly of multiple Type I cylinders

- Maximum working pressure: 100-150-200 bar (Customizable for customers) Homogeneous gas distribution with integrated manifold

- Compact design and high volume efficiency

- Continuous monitoring with pressure, temperature, and safety sensor.

Safety Features

- Pressure Relief Valves & Gauges: Prevent overpressure and allow continuous monitoring.

- Hydrogen Leak Detection: Immediate alert in case of gas leaks.

- Static Grounding & Ventilation: Minimize ignition risk and ensure safe gas dispersion.

- Protective Enclosures: Shield cylinders from mechanical damage.

- Emergency Shut-Off Valves: Quick isolation in case of any hazard.

Why Work with Us?

Our advanced Type I cylinders and bundle systems set the industry standard for safety, durability, and operational efficiency.

- High engineering and manufacturing quality

- Solutions tailored for industrial, energy, and mobility sectors

- Installation, maintenance, and safety compliance support

- Continuous gas supply and operational continuity

Get ready for the future with our solutions that harness hydrogen's clean energy potential in the safest and most efficient way.