Challenges in Hydrogen Pipeline Pig Launchers & Receivers Design and Operations

As global energy industries shift toward cleaner, renewable energy sources, hydrogen is emerging as a key player in the future of energy storage and transportation. Hydrogen, whether blended with methane or transported in its pure form, presents numerous technical challenges, especially for existing pipeline infrastructures. Among the most significant hurdles are the design and operational safety of pig launchers and receivers, critical components in pipeline maintenance and integrity.

Hydrogen Properties and Risks

Hydrogen's unique physical and chemical properties make it a highly efficient energy carrier, but also introduce new complexities. Unlike methane, hydrogen has a much wider flammability range (4% to 75% when mixed with air). It also requires lower ignition energy. These properties make hydrogen far more prone to accidental combustion. Its small molecular size allows it to leak through materials that would otherwise contain other gases, and it can exacerbate the degradation of pipeline materials, such as steel, leading to an increased risk of corrosion and material failure.

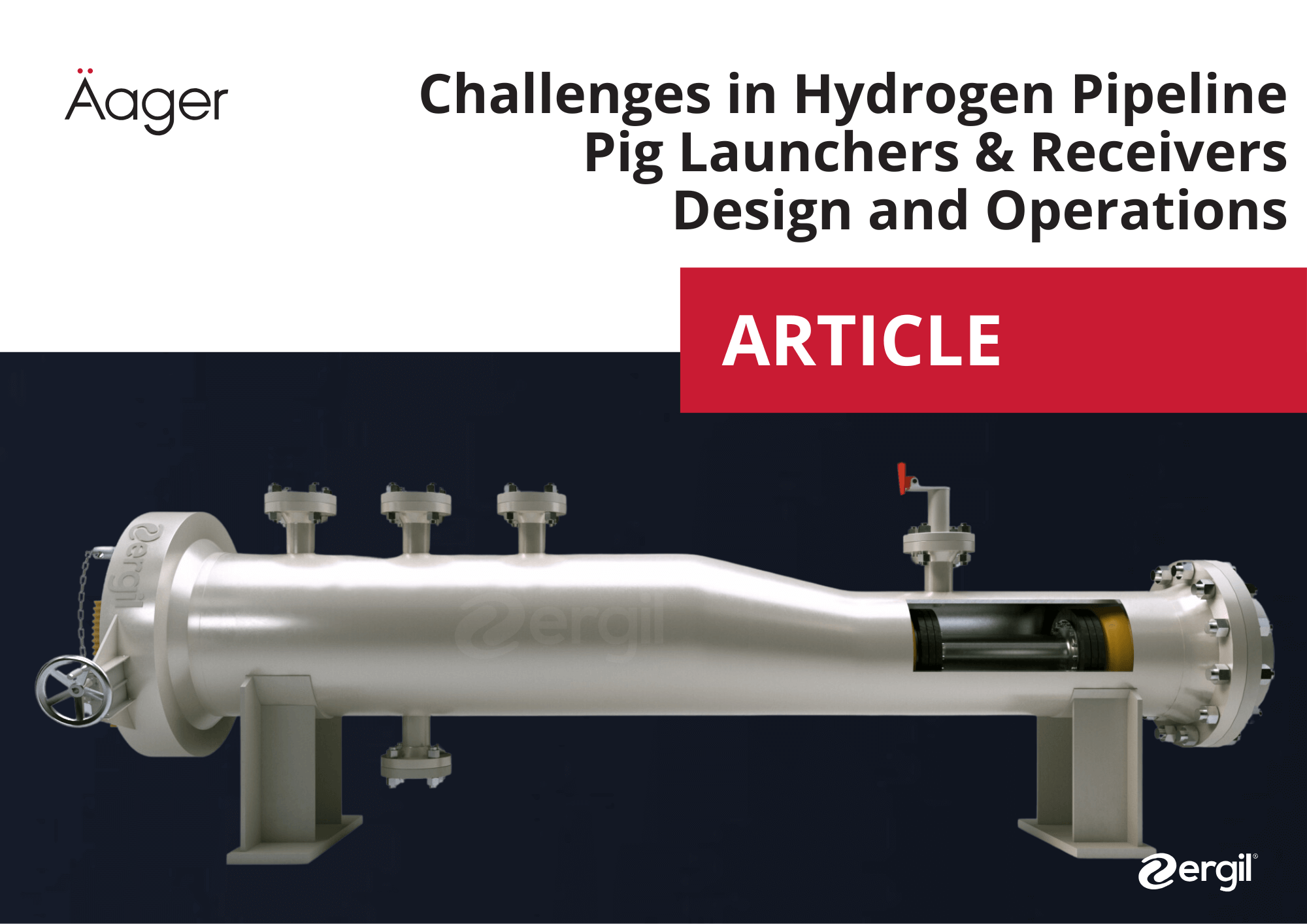

These factors complicate the operations of pig launchers and receivers. In traditional gas pipelines, pigs (devices inserted into the pipeline for cleaning and inspection) are essential for maintaining the integrity of the system. However, in pipelines carrying hydrogen, the act of launching and retrieving pigs becomes significantly more hazardous due to hydrogen's increased volatility and the potential for explosive atmospheres when containment is broken. Compounding these challenges are the fact that there are currently no well-established international standards specifically addressing hydrogen pipeline pigging, leaving operators to adapt from existing standards, which may not fully account for hydrogen's unique risks.

Design Challenges for Pig Launchers and Receivers

One of the primary challenges in hydrogen pipeline pigging operations is designing launchers and receivers that can handle the specific risks posed by hydrogen. Key considerations include:

- Material Selection: Traditional materials used in pigging equipment may not be compatible with hydrogen, which can cause embrittlement or degradation of seals, brushes, and other components. At ERGIL, we ensure that our pigging systems are made with materials specifically tested for hydrogen service, offering enhanced resistance to hydrogen permeation and wear.

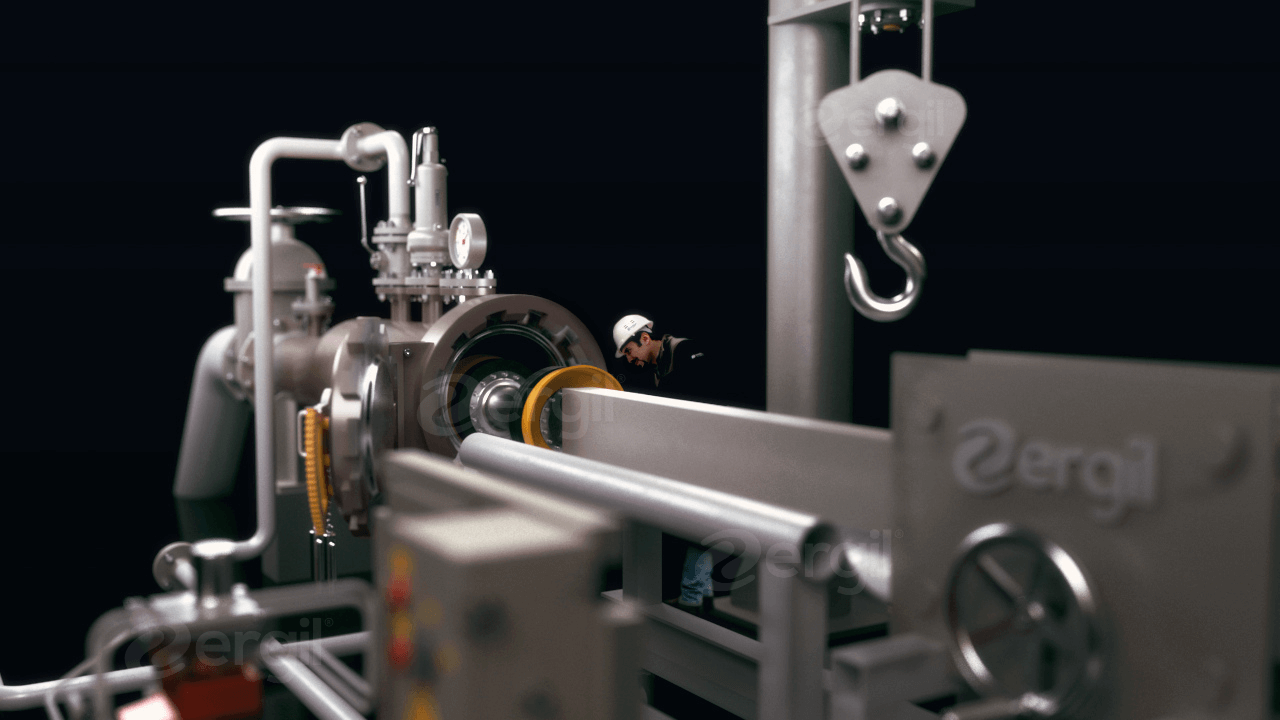

- Safety in Operations: Due to the high flammability and leak potential of hydrogen, pigging operations require meticulous safety procedures. This includes careful venting of the pipeline to remove hydrogen before launching or receiving a pig, inerting with nitrogen, and using explosion-proof equipment in hazardous environments. At ERGIL, our pigging systems are designed with safety features, such as pressure control systems, to ensure that pigs are launched and retrieved in a controlled manner, minimizing the risk of accidents.

- Control of Pig Velocity: Hydrogen's low density and compressibility make it difficult to control pig velocity, which is critical for both cleaning and Data Acquisition in In-line Inspection (ILI) operations. A pig moving too quickly can miss areas of corrosion or fail to remove debris effectively. Our advanced pigging systems at ERGIL incorporate precise velocity control mechanisms, ensuring that pigs travel at a consistent speed, even in challenging hydrogen environments.

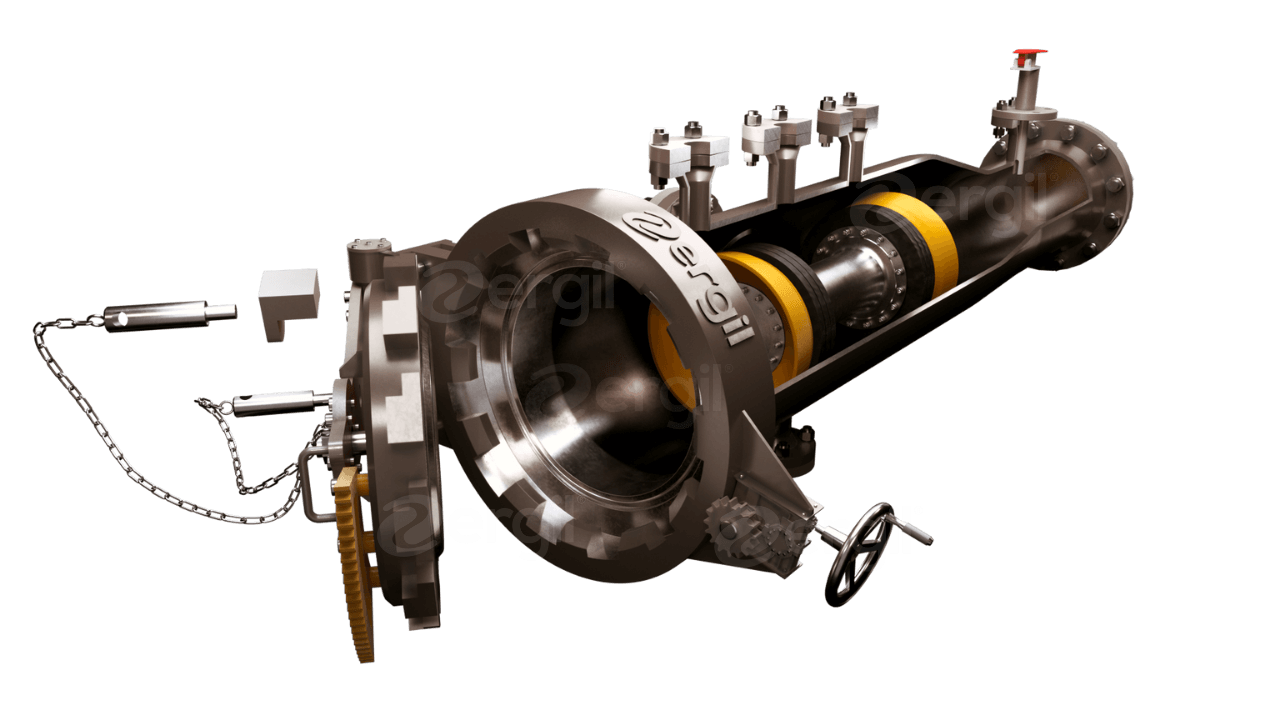

- Mechanical Components: The proper functioning of mechanical moving parts is vital in ensuring safe and efficient pigging operations. This includes pig handling systems like jib cranes and trolleys, which facilitate the safe loading and unloading of pigs; quick-opening closures that provide secure and fast access to launchers and receivers while preventing hydrogen leaks; pig signals that accurately track pig movements; and valves and interlocking systems that ensure the correct sequence of operations, preventing hazardous pressure build-up or gas leaks. At ERGIL, we design these components to withstand the specific demands of hydrogen service, ensuring optimal safety and performance.

Operational Challenges

Beyond the technical aspects of equipment design, operational challenges in hydrogen pigging are significant. These include:

- Training and Personnel Safety: With hydrogen pipelines, operational personnel must undergo specialized training to handle the unique hazards posed by hydrogen. Procedures for breaking containment, venting, and inerting must be rigorously followed. At ERGIL, we offer comprehensive support and training programs to ensure that teams can operate our pigging equipment safely and effectively.

- Maintenance and Integrity Monitoring: Hydrogen pipelines require more frequent maintenance due to the potential for increased corrosion. In-line Inspection tools (ILI) must be regularly deployed to detect and mitigate any threats to pipeline integrity. ERGIL's pigging systems are compatible with a range of ILI tools, ensuring that operators can monitor pipeline conditions and take action before failures occur.

The Future of Hydrogen Pipeline Pigging

As the energy industry moves towards net-zero carbon emissions, hydrogen pipelines will play an increasingly important role. However, the challenges in safely operating and maintaining these pipelines cannot be underestimated. The lack of standardized protocols for hydrogen pipeline pigging further complicates the situation, requiring industry leaders to adopt best practices that ensure safety and reliability. The design and operation of pig launchers and receivers must evolve to meet the specific demands of hydrogen, incorporating advanced materials, enhanced safety features, and precise operational controls.

At ERGIL, we are committed to leading the way in hydrogen pipeline pigging technology. Our comprehensive range of pigging equipment is designed to meet the highest safety and performance standards, ensuring the safe and efficient operation of hydrogen pipelines around the world. By addressing the unique challenges posed by hydrogen, we help our clients achieve their energy goals while protecting both assets and personnel.

For more information on our pigging solutions, visit https://ergil.com/pipeline-pigging-systems/.