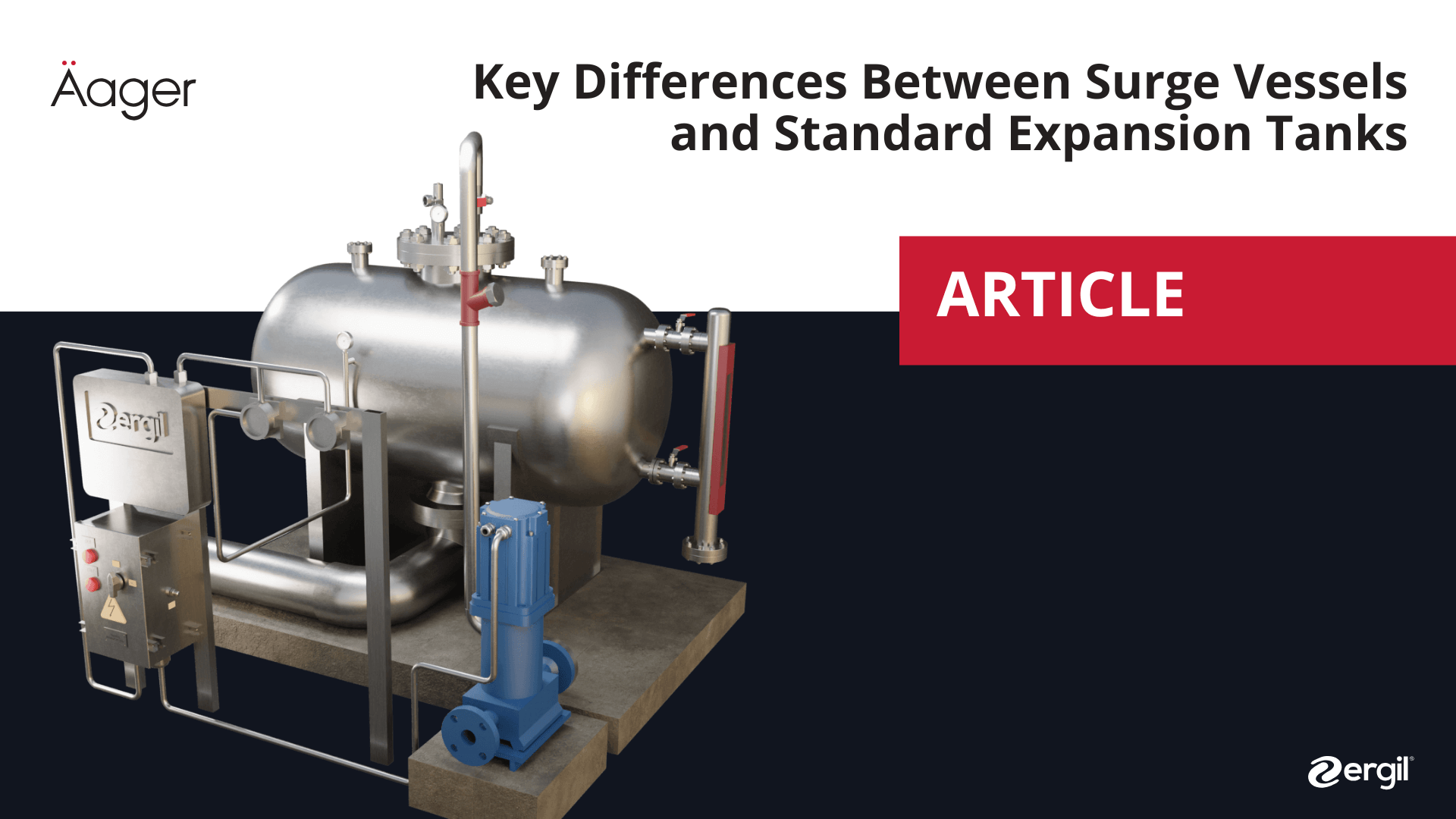

Key Differences Between Surge Vessels and Standard Expansion Tanks

When it comes to fluid systems, many customers often compare surge vessels to standard expansion tanks. While these two components may appear similar at first glance, they serve very different purposes and are designed to meet vastly different performance and safety standards. At ERGIL, we manufacture high-quality, high-standard surge vessels, which go far beyond what standard expansion tanks can offer. This article will highlight the critical differences to educate our customers and ensure they make informed decisions for their systems.

1. Purpose and Functionality

Surge Vessels:

Surge vessels are specifically designed to protect pipelines and pumping systems from water hammer, pressure surges, and transient events caused by sudden changes in fluid flow. They act as shock absorbers, mitigating dangerous pressure spikes that can result in significant damage to pipelines, valves, and other equipment. Surge vessels ensure system stability, minimize the risk of downtime, and prolong the life of the entire system.

Expansion Tanks:

In contrast, standard expansion tanks are primarily used to accommodate thermal expansion in closed-loop heating or cooling systems. As the temperature of the fluid increases, the liquid expands, and the expansion tank absorbs the additional volume to maintain system pressure within safe limits. They are not designed to handle sudden pressure spikes or dynamic surges.

Key Difference: Surge vessels manage rapid, dynamic pressure changes (water hammer) while expansion tanks address slow, thermal pressure changes.

2. Design and Engineering Standards

Surge Vessels:

Surge vessels are highly engineered products that must comply with stringent international standards such as ASME, PED, or API. They are custom-designed to match system specifications, including maximum operating pressure, flow rates, and transient analysis. Materials, welding processes, and coatings are carefully selected to ensure long-term durability and reliable performance under extreme pressure fluctuations.

ERGIL offers various types of surge vessels tailored for specific applications, including:

- Heavy-Duty Bladder Tanks: These include a pre-charged bladder that separates liquid and gas, effectively absorbing high-pressure surges.

- Dip Tube Type Surge Vessels: Designed for systems where direct fluid-to-gas interaction is managed through internal dip tubes to cushion pressure spikes.

- Compressor-Type Surge Vessels: These are integrated with a compressor system to maintain pressure stability in critical applications, particularly in large-scale pipelines.

- AWWA-Approved Internal Bladder Vessels for Drinking Water: ERGIL provides AWWA-approved surge vessels with internal bladders specifically designed for drinking water applications, ensuring safe, hygienic, and reliable performance.

Expansion Tanks:

Standard expansion tanks, on the other hand, are mass-produced and follow less demanding manufacturing standards. They are typically made for lower operating pressures and are not subjected to the same rigorous testing and quality assurance as surge vessels.

Key Difference: Surge vessels are custom-engineered for specific systems, whereas expansion tanks are off-the-shelf solutions with limited application flexibility.

3. Pressure and Volume Handling

Surge Vessels:

Surge vessels are designed to withstand high pressures and rapid pressure changes. They often include pre-charged nitrogen gas or an air cushion to absorb energy during pressure surges. The vessel’s size and pressure rating are carefully calculated based on detailed transient analysis to ensure adequate protection. ERGIL's surge vessels can range in size and capacity from a few hundred liters to thousands of liters, making them suitable for large-scale applications.

Expansion Tanks:

Expansion tanks operate at relatively lower pressures and are typically smaller in size. They are designed only to handle gradual volume increases caused by thermal expansion, not the sudden shockwaves created by surge events. Standard expansion tanks are generally limited to small systems, with capacities ranging from just a few liters to a couple of hundred liters.

Key Difference: Surge vessels can handle extreme pressures and large capacities, while expansion tanks are limited to low-pressure, small-volume thermal changes.

4. Applications

Surge Vessels:

- Water supply systems (municipal and industrial)

- Pumping stations

- Pipelines (long-distance water, oil, and gas systems)

- Fire protection systems

- Wastewater treatment facilities

- Drinking water systems (AWWA-approved internal bladder vessels)

Expansion Tanks:

- HVAC systems (heating, ventilation, and air conditioning)

- Boiler systems

- Domestic hot water systems

Key Difference: Surge vessels are critical for large-scale, dynamic systems that face high pressure transients, while expansion tanks are used for smaller, temperature-driven applications.

5. Cost and Value

Surge Vessels:

Due to their custom engineering, advanced materials, and rigorous testing, surge vessels come at a higher cost. However, this investment pays off by protecting critical systems from catastrophic failures, costly repairs, and unplanned downtime.

Expansion Tanks:

Expansion tanks are low-cost, commodity products intended for basic thermal expansion management. They are not suitable for protecting systems from high-pressure surges.

Key Difference: Surge vessels are a long-term investment in system safety and reliability, whereas expansion tanks offer a low-cost solution for simpler systems.

6. Graphical Comparison

Below is a graphical comparison between surge vessels and standard expansion tanks based on critical performance parameters such as pressure handling, volume capacity, design flexibility, cost, application range, durability, maintenance, and system protection.

| Parameter | Surge Vessels | Expansion Tanks |

|---|---|---|

| Pressure Handling | 9/10 | 4/10 |

| Volume Capacity | 9/10 | 3/10 |

| Design Flexibility | 9/10 | 5/10 |

| Cost | 5/10 | 9/10 |

| Application Range | 10/10 | 3/10 |

| Durability | 9/10 | 4/10 |

| Maintenance | 7/10 | 8/10 |

| System Protection | 10/10 | 4/10 |

Why High-Standard Surge Vessels Matter

At ERGIL, we design and manufacture surge vessels that meet the most demanding engineering and performance standards. Comparing surge vessels to standard expansion tanks is not just an oversimplification but a misunderstanding of their fundamentally different roles. Surge vessels are essential for safeguarding pipelines and pumping systems against destructive pressure surges, whereas expansion tanks handle thermal expansion in much simpler applications.

ERGIL's heavy-duty bladder tanks, dip tube type surge vessels, compressor-type surge vessels, and AWWA-approved internal bladder vessels for drinking water are built to handle extreme operating conditions with large capacities, providing unmatched performance and safety.

When it comes to protecting your system, investing in the right solution is crucial. High-standard surge vessels ensure safety, reliability, and operational efficiency, far beyond what a standard expansion tank can achieve.

If you have any questions or need further clarification on surge vessel applications, our team at ERGIL is here to assist you. Let us help you make the right choice for your system’s protection and performance.

Visit our product at: https://ergil.com/surge-vessels/