Industrial Storage Tanks & Pressure Vessels

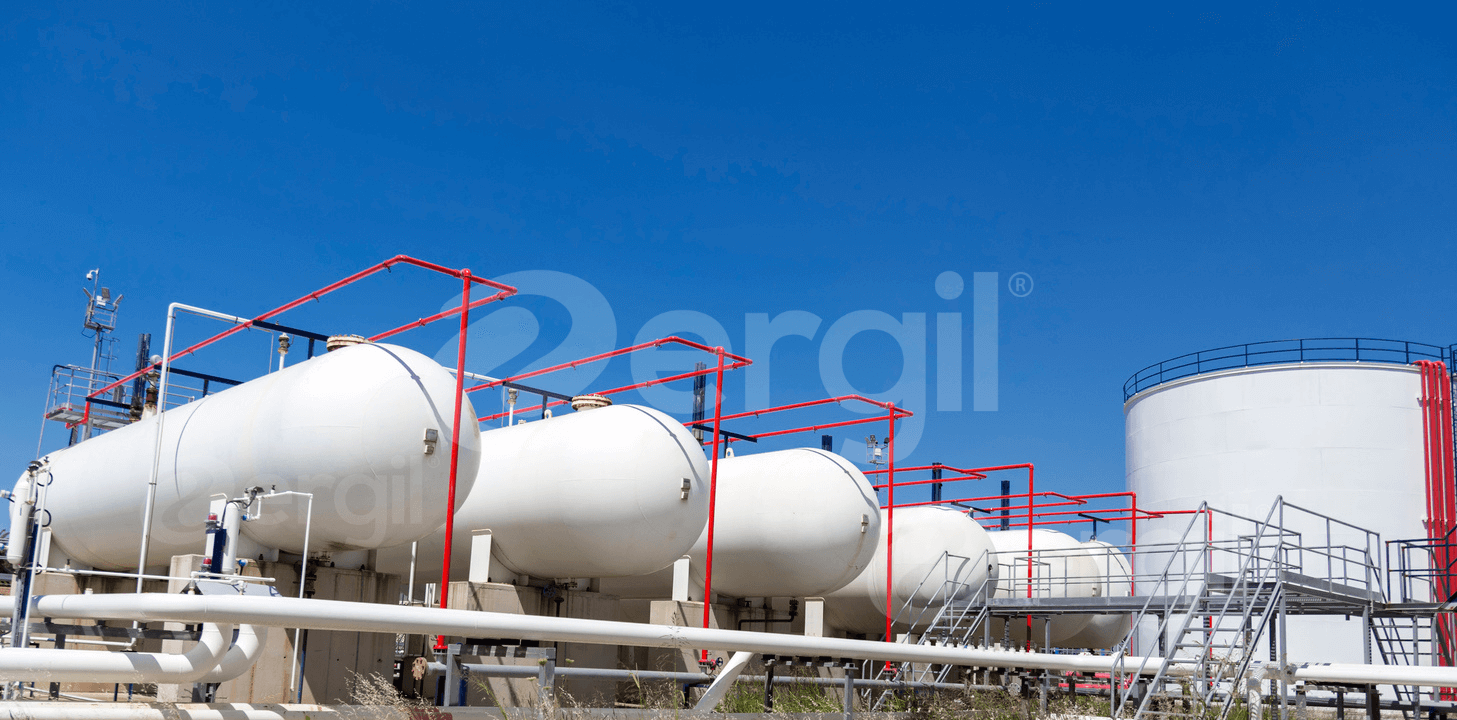

New Generation Storage Tank Terminals; Safe, Environmental and Sustainable

Increasing health, safety and environmental concerns lead to new regulations that in return increase the cost of designing, building, and operating storage facilities.

We at ERGIL are committed to provide most economical, environmentally friendly, and safe storage solutions.

Thanks to our 40 years of experience, we have witnessed almost all the challenges and found collective solutions for the pressurized and atmospheric storage tank industry.

From the conceptual design to commissioning, ERGIL provides unique solutions for storage tank terminals.

Keeping customers’ requirements in mind, we follow latest industry standards, regulations and cost effective solutions.

Storage Tanks

Safeguarding Resources and Streamlining Operations

Storage tanks play a crucial role in inventory management, supply chain operations, and ensuring a steady and controlled flow of materials in various industries.

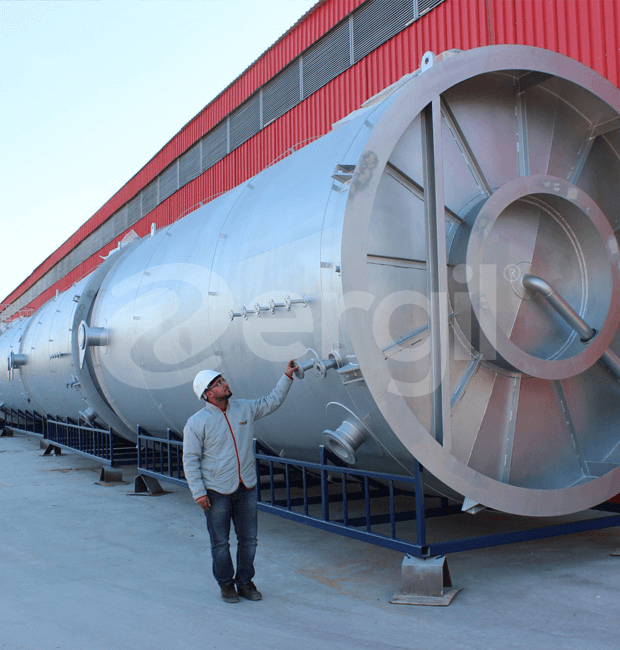

Advanced Pressure Vessel Manufacturing Solutions

Comprehensive Capabilities in Pressure Vessel Fabrication

ERGIL specializes in the design and manufacturing of pressure vessels, setting the standard for precision, reliability, and engineering excellence. Our fully equipped manufacturing facility, covering over 20,000 m² in the Mersin Tarsus Industrial Zone, is built to handle complex and high-performance projects. ERGIL delivers tailored solutions to meet the specific requirements of industries including oil and gas, petrochemical, energy, and beyond.

Design and Engineering Expertise

ERGIL designs pressure vessels in strict accordance with internationally recognized standards, including ASME, EN, and GOST. Our engineering team leverages advanced simulation tools and design methodologies to ensure precision, performance, and compliance with project specifications.

Certified Excellence Beyond Compliance

ERGIL is not only compliant with international standards but also a certified manufacturer for the following:

- DNV Marine

- AD200

- EN ISO 3834-2

- EN 1090

- ASME (including U Stamp, S, and R certifications)

- UL, ATEX, and GOST

These certifications reflect our commitment to quality and our ability to deliver products that meet the most stringent regulatory requirements.

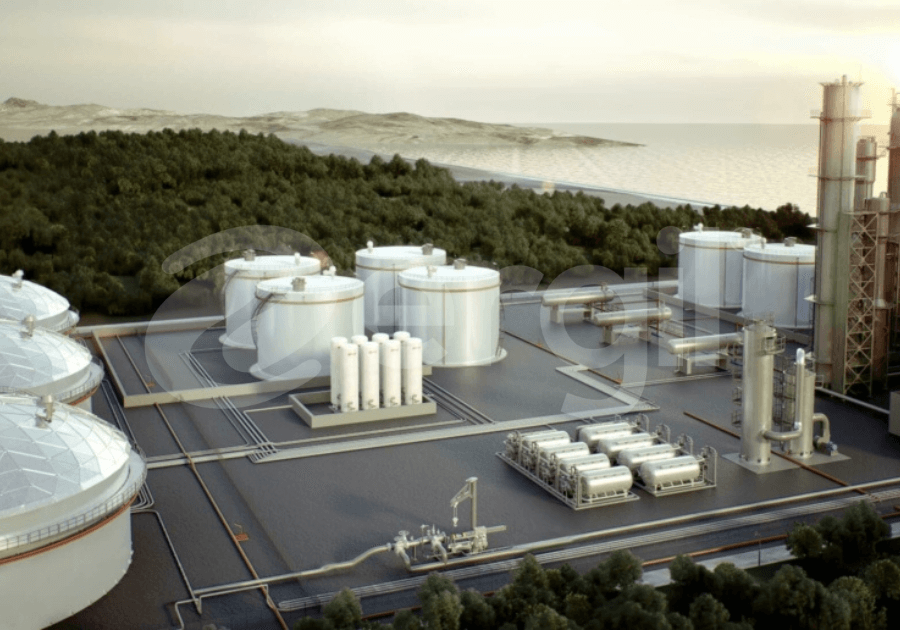

Turn-Key Storage Facility Solutions

At ERGIL, we specialize in delivering comprehensive turn-key solutions for storage facilities, encompassing engineering, procurement, fabrication, and construction.

Our expertise spans a wide range of applications, including atmospheric tank farms, LPG storage, LNG terminals, chemical storage tanks, and more, catering to various industries such as oil and gas, petrochemicals, water treatment, and energy.

Extreme Performance Capabilities

ERGIL is a leader in fabricating pressure vessels for high-stress applications:

- Pressure vessels capable of operating at 400 bars and above.

- Plate thicknesses exceeding 140 mm, designed for extreme conditions.

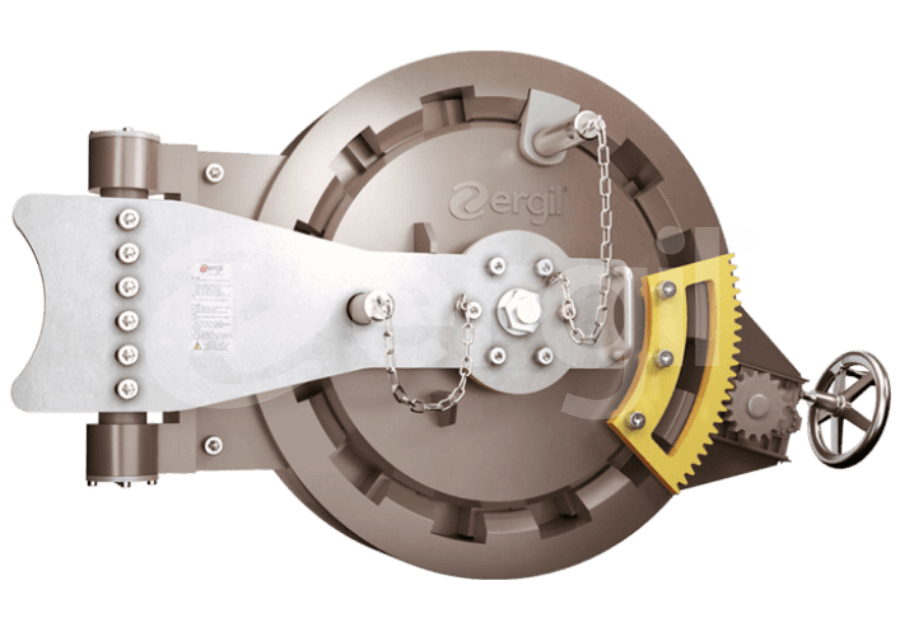

Specialized Quick-Opening Closures

Our RX1 and RX2 quick-opening closures are globally recognized for their efficiency and robust construction. These closures provide easy access solutions for high-pressure systems, streamlining operational workflows. Learn more about these innovations at RX Closure.

Material Expertise for All Applications

ERGIL has extensive experience in fabricating pressure vessels from a wide range of materials, including:

- Conventional Stainless Steels: SS304L, SS316L, SS316TI.

- High-Performance Alloys: Duplex, Super Duplex, LDX.

- Exotic Materials: Aluminum, Copper, Titanium, Inconel, Alloy31.

- Carbon Steels: Structural and pressure vessel grades conforming to ASME, EN, and GOST standards.

We maintain a comprehensive archive of Welding Procedure Specifications (WPS) and Procedure Qualification Records (PQR), enabling seamless adaptation to both standard and novel material applications.

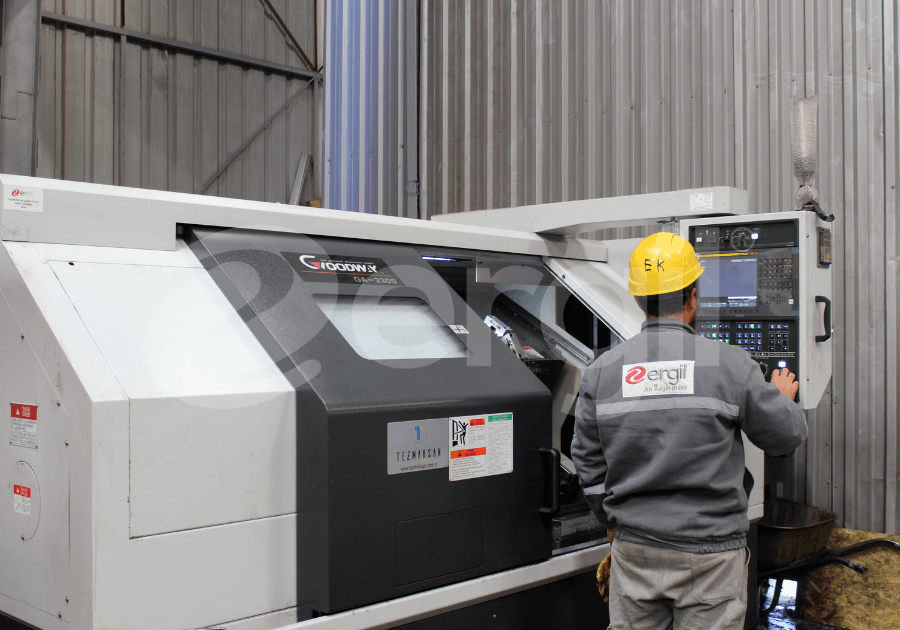

State-of-the-Art Manufacturing Processes

ERGIL employs cutting-edge technologies to ensure precision and efficiency across all manufacturing stages:

- Welding Systems: Advanced robotic and plasma welding (MIG, TIG, orbital, and column boom welding systems).

- Machining Workshop: Equipped with CNC machining centers for diameters up to 2,000 mm, semi-CNC vertical lathes (up to 1,600 mm), and universal horizontal lathes for versatile machining requirements.

- Automated Cutting and Forming: CNC cutting benches and high-precision bending machines ensure consistent quality in forming processes.

Our facility integrates these advanced systems with stringent quality control, ensuring repeatable and reliable results.

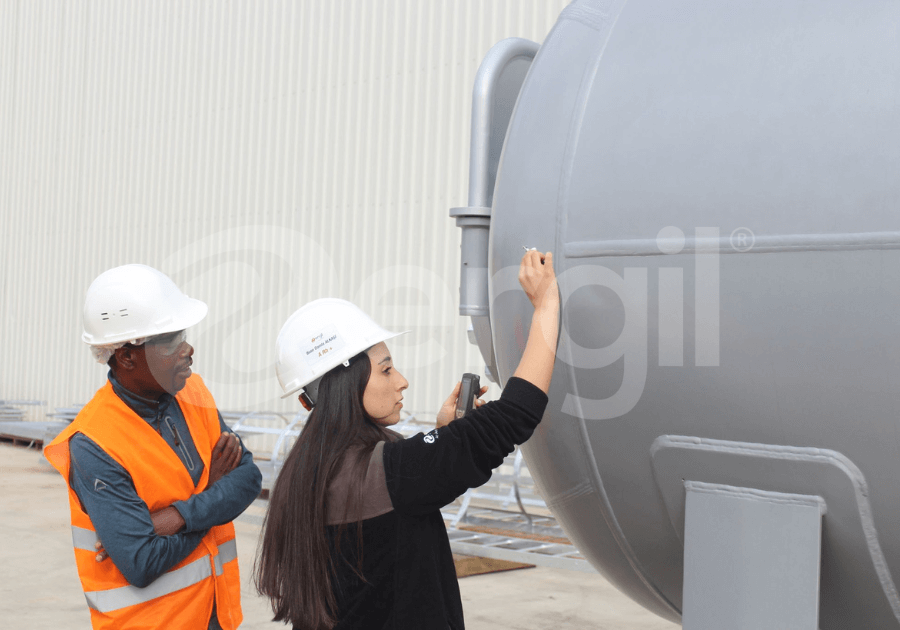

Quality Control and Traceability

Quality assurance at ERGIL is embedded in every step of the manufacturing process:

- All materials undergo thorough inspection, with traceability ensured through an ERP-integrated system.

- Compliance is backed by our certifications in DNV Marine, AD200, EN ISO 3834-2, EN 1090, ASME (U Stamp, S, R), UL, ATEX, and GOST.

- Detailed quality control records, including material test certificates and heat numbers, are meticulously documented and provided to clients upon request.

This robust quality management system ensures every vessel meets the highest standards of performance and durability.

Applications Across Diverse Industries

ERGIL pressure vessels are engineered for a wide range of industrial applications, including:

- Chemical Processing

- Water and Wastewater Treatment

- Power Generation and Nuclear Energy

- Marine and Offshore Applications

- Pharmaceutical Manufacturing

- Semiconductor and Chip Production

- Food and Beverage Processing

Our ability to customize designs and materials ensures suitability for specific operational conditions, including extreme temperatures, corrosive environments, and high-pressure systems.

Storage Tanks Models

Request A Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon

Engineering Excellence for Critical Applications

ERGIL’s extensive experience, advanced manufacturing capabilities, and industry-leading certifications make us a trusted partner for pressure vessel solutions. With a focus on precision engineering and adherence to the highest standards, we provide durable and efficient systems that meet the most demanding requirements.

Specialized Applications in Pressure Vessel Manufacturing

FRP and GRP Linings for Chemical Resistance

For applications requiring lightweight and highly corrosion-resistant materials, ERGIL provides FRP (Fiberglass Reinforced Plastic) and GRP (Glass Reinforced Plastic) linings. These materials are ideal for environments with aggressive chemicals or saline water exposure, such as in chemical processing, marine, and water treatment industries. FRP and GRP offer high mechanical strength and exceptional resistance to environmental degradation.

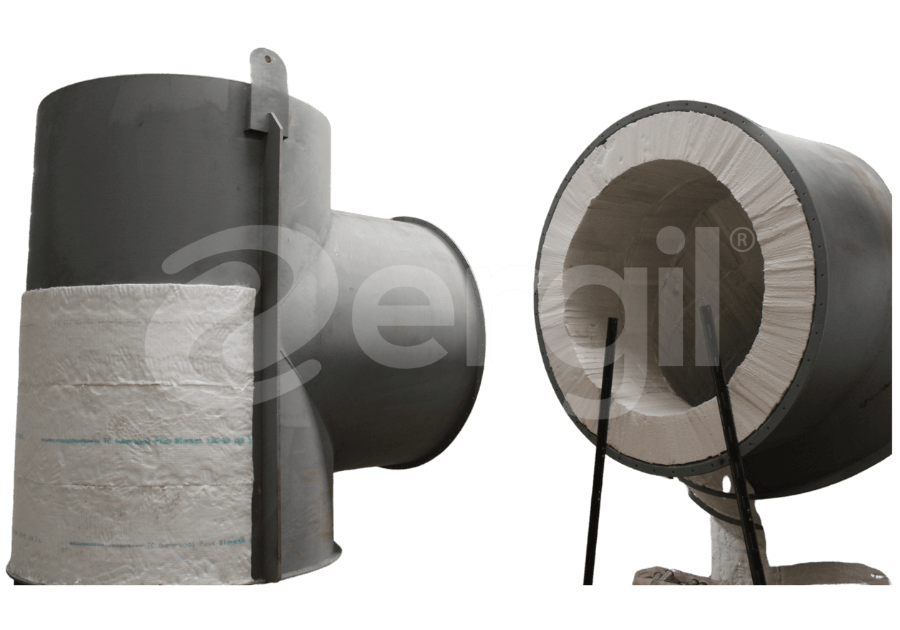

Special Insulation & Refractory Linings for Extreme Temperatures

ERGIL provides advanced insulation solutions for high-temperature applications. For instance, we engineered insulation systems for a Combustion Chamber and Air Quench using 300 mm thick ceramic fiber for internal insulation and 25 mm thick mineral wool for outer insulation.

This robust insulation design ensures excellent thermal resistance, enabling the equipment to operate reliably under extreme conditions while maintaining efficiency and safety. ERGIL offers refractory lining solutions designed to withstand extreme temperatures in high-heat environments such as combustion chambers and thermal reactors.

These linings provide excellent resistance to thermal shock, abrasion, and chemical attack, ensuring the durability and efficiency of pressure vessels under the most demanding operating conditions.

Special Lining for Potable Water Applications

ERGIL offers custom lining solutions for potable water storage and transport systems. Using certified food-grade coatings and linings, we ensure compliance with stringent health and safety regulations.

Our solutions provide a durable, corrosion-resistant internal lining, maintaining water purity and extending the lifespan of pressure vessels used in potable water applications.

Rubber Lining and Coating for Corrosion Protection

For environments prone to severe chemical exposure, ERGIL utilizes rubber lining and coating technologies. These linings offer exceptional resistance to acids, alkalis, and other corrosive substances, making them ideal for chemical processing and wastewater treatment industries.

Our precision application techniques ensure a uniform and reliable barrier against corrosion, enhancing the durability of the pressure vessels. ERGIL also specializes in ebonite (hard rubber) coatings, which are highly resistant to abrasion, chemical exposure, and corrosion.

These coatings are particularly well-suited for industries handling caustic substances or abrasive slurries. With precise application methods, ERGIL ensures long-lasting protection and reduced maintenance for pressure vessels in harsh operating environments.

Stainless Steel Overlay Welding for Corrosive Environments

To further enhance resistance to corrosion, ERGIL provides stainless steel overlay welding solutions. This technique involves applying a corrosion-resistant stainless steel layer over carbon steel substrates, offering the structural benefits of carbon steel with the superior corrosion resistance of stainless steel. Our overlay welding is performed with precision, ensuring a seamless and defect-free surface for demanding applications.

Post Weld Heat Treatment (PWHT) for Structural Integrity

ERGIL incorporates post weld heat treatment (PWHT) to relieve residual stresses and enhance the mechanical properties of pressure vessels after welding. PWHT is essential for applications involving high pressures and temperatures, ensuring long-term structural integrity and minimizing the risk of material fatigue or failure.

Our advanced heat treatment processes are precisely controlled to meet industry-specific requirements.

Projects

Discover Our Global Success Stories: Join the Journey of Inspiration!

News, Events & Case Studies

Dive into a World of Knowledge and Insight: Explore Our News, Events, Articles, and Case Studies!

Storage Tanks FAQ's

Find Out More About Us

Our people are our biggest asset but the only way to unlock their potential is to invest in the right business systems that encourage innovation.

40+ Years in Business

40+ Years in Business More than 40 years of experience

Easily Reachable

Worldwide Offices and Representatives

Superior After Sales Support

Long-term business partnerships

Certifications ATEX, ASME, ISO, CE

High-end Production Facility

35,000 square meter manufacturing facility

Being leader in manufacturing better, safer, and economical products

Contribute positively to our communities and environments well as to ensure highest level of customer satisfaction through the highest standards of excellence in our products and services, and comprehensive environmental regulations. Working everyday for the creation of better products that protects environment, people and assets.

Our history begins in 1938 and goes on together with all our parties.

- 1983 - Founded

- 1987 - Added 100. product to its portfolio

- 1991 - Certified products and services

- 2005 - Opened its first international office

- 2010 - Became market leader in 11 countries

- 2010 - Invested heavily in new manufacturing facility

- 2015 - Build one of the biggest R&D in its-field

- 2018 - Became part of Äager