Pipeline Pigging System

Crucial Part of Your Pipeline Operation Integrity; Safe, Reliable and Sustainable

Pipeline pigging systems are the heart and soul of any pipeline. They are the crucial part for the operation. Pipeline pig stations are used for pipeline inspection, cleaning, maintenance and help flow of multiple products at the same time.

Due to the increasing safety, environmental and operational cost, pipeline operation is more expensive than before. Todays’ pipeline operators are looking for more reliable, safe and sustainable solutions.

Thanks to 40 years of experience, ERGIL provides unique solutions for pipeline pigging stations.

Pipeline Pigging Systems

Safe, Reliable and Sustainable

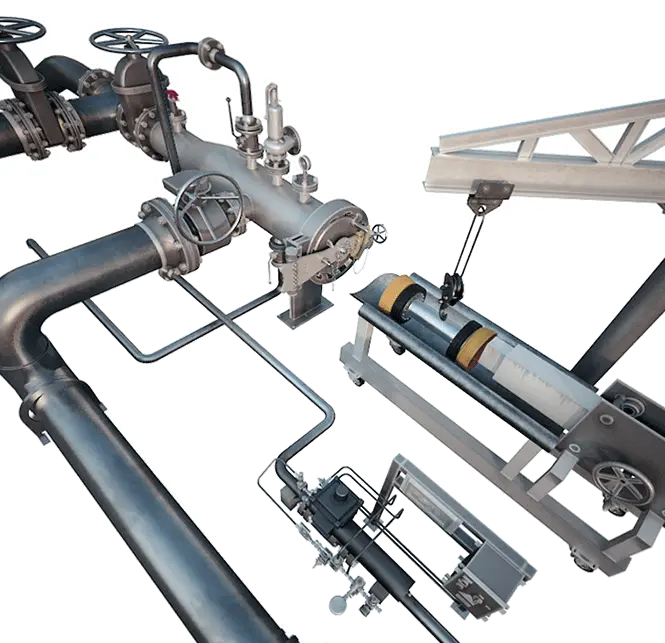

Pipeline pigging systems use specialized devices called pigs to clean, inspect, or separate different products within pipelines for efficient and safe operations.

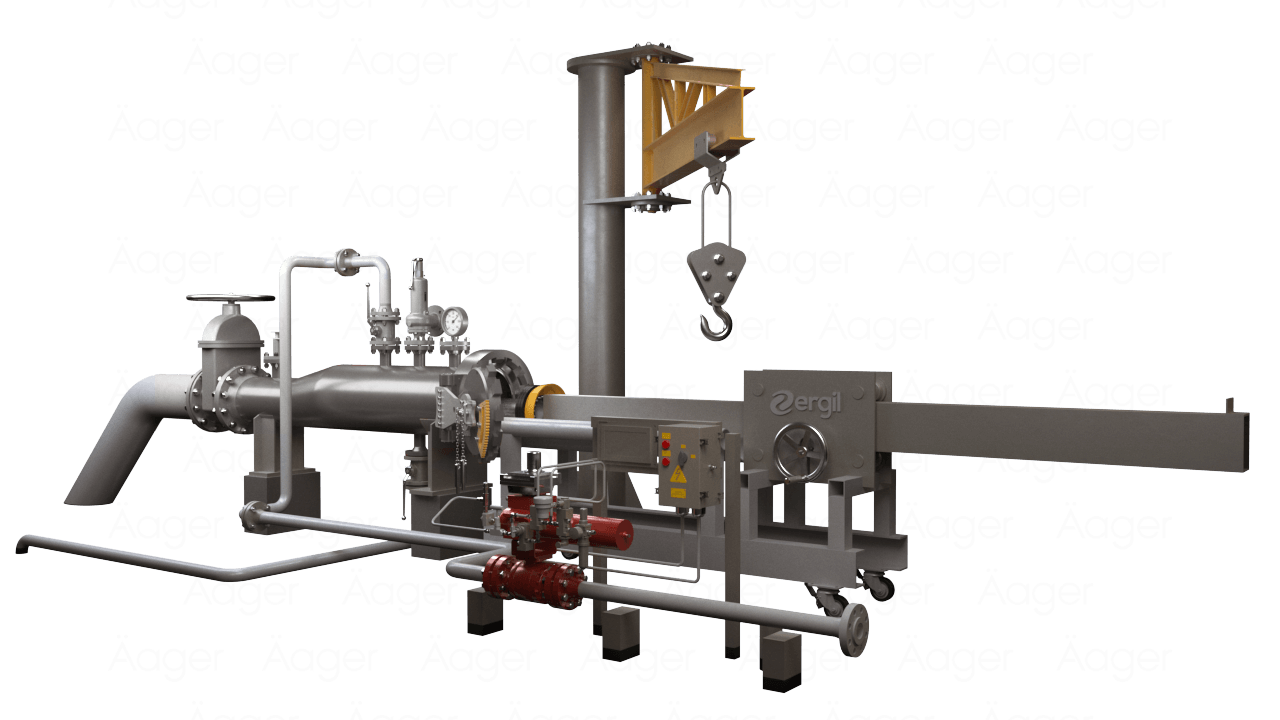

Custom-made Modular Skid Systems

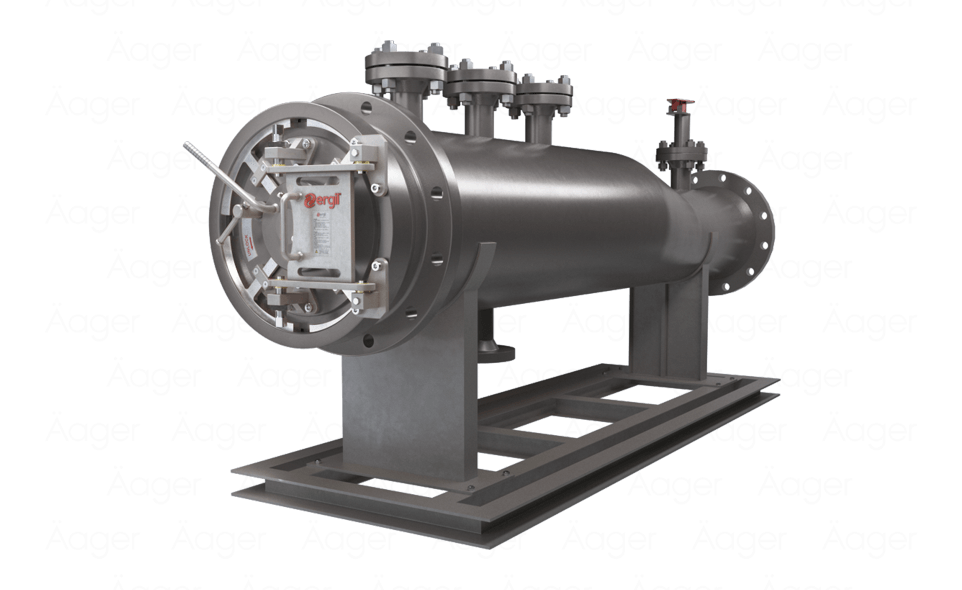

Certified High Pressure Pig Launcher & Receiver

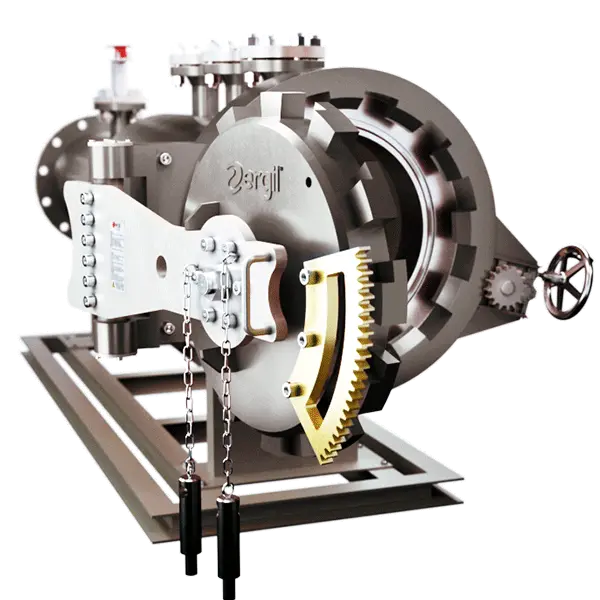

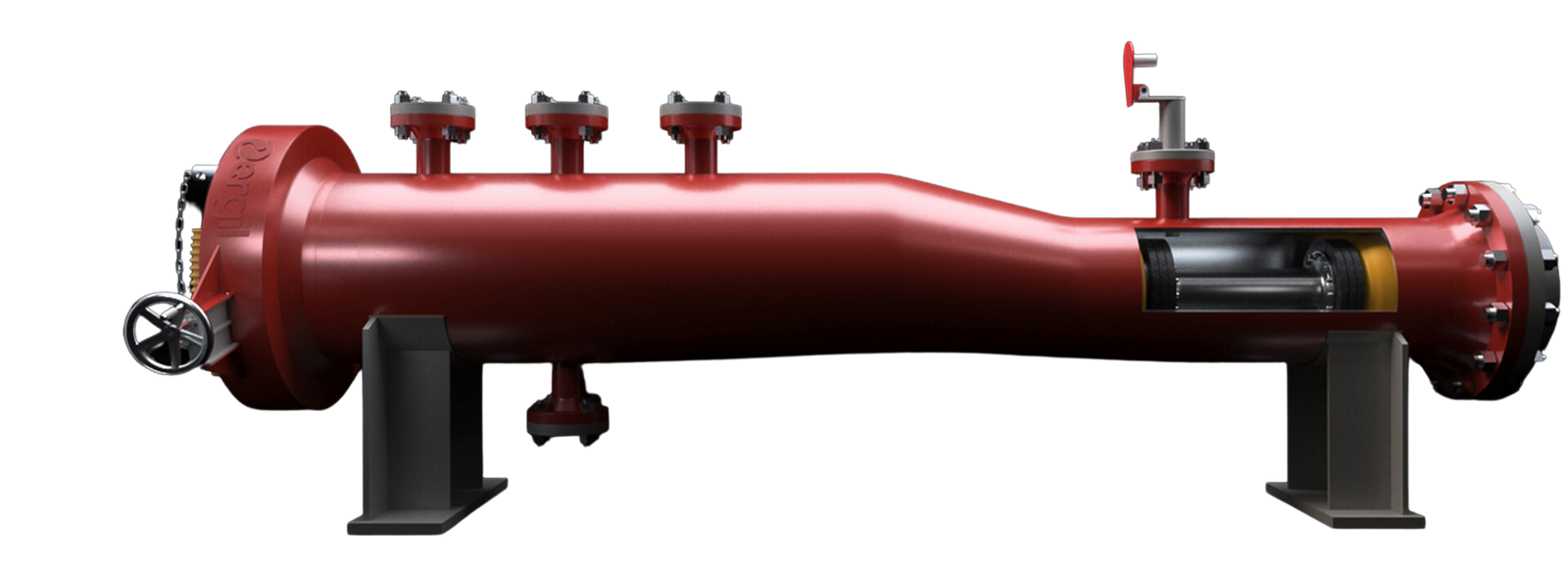

Since 1982, ERGIL has been dedicated to the design and fabrication of high-pressure vessels tailored to meet specific requirements. Among these vessels, the pig launcher & receiver holds paramount importance as a vital component of the pigging system.

Designing and manufacturing high pressure pig launchers & pig receivers requires certain specialization that has to be accredited by industrial authorities.

ERGIL designs and manufactures pressure vessels up to 690 bar with maximum thickness 150 mm.

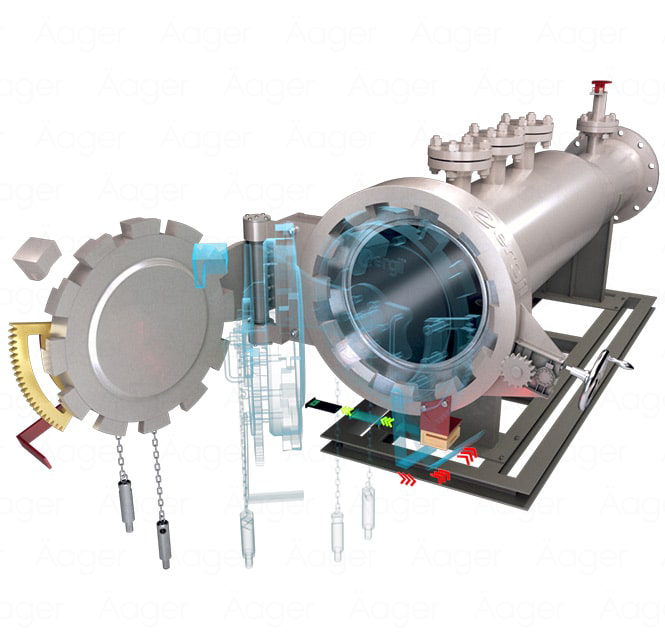

Modular Skid Pig Launcher & Receiver Systems

Our fabrication facility and personnel are certified with ASME U, S, R, NBR, GOST, AD 2000/ISO 3834, EN 1090-1, EN ISO 3834-2, & DNV GL + ABS Marine Welding Class Program and capable of designing and manufacturing as per ASME, EN, GOST & as per end user requirements; such Shell DEP.

ERGIL’s modular pigging stations provide all you need on a single skid. ERGIL designs mobile or permanent frames with adjustable height mechanisms, so moving from one place to another and using it for multiple pipelines is possible.

Support & Delivery

They are easy to transport from one location to another. Modules can be designed as per the shipping method (sea, road and even air) and the system can be customizable as per working environment to protect against rush weather effects or robbery.

Traditional pigging system contraction is costly, takes time, and safety concerns are high, however ERGIL’s mobile modular skid pig launcher & receiver plug and play systems can reduce your project cost and time drastically in addition to eliminating site accidents. Contractors do not need to deal with site installation of such complicated systems.

Pipeline Pigging System Models

Request A Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon

Projects

Discover Our Global Success Stories: Join the Journey of Inspiration!

News, Events & Case Studies

Dive into a World of Knowledge and Insight: Explore Our News, Events, Articles, and Case Studies!

Pipeline Pigging System FAQ's

Find Out More About Us

Our people are our biggest asset but the only way to unlock their potential is to invest in the right business systems that encourage innovation.

More than 40 years of experience

Easily Reachable

Worldwide Offices and Representatives

Superior After Sales Support

Long-term business partnerships

Certifications ATEX, ASME, ISO, CE

High-end Production Facility

35,000 square meter manufacturing facility

Being leader in manufacturing better, safer, and economical products

Contribute positively to our communities and environments well as to ensure highest level of customer satisfaction through the highest standards of excellence in our products and services, and comprehensive environmental regulations. Working everyday for the creation of better products that protects environment, people and assets.

Our history begins in 1938 and goes on together with all our parties.

- 1983 – Founded

- 1987 – Added 100. product to its portfolio

- 1991 – Certified products and services

- 2005 – Opened its first international office

- 2010 – Became market leader in 11 countries

- 2010 – Invested heavily in new manufacturing facility

- 2015 – Build one of the biggest R&D in its-field

- 2018 – Became part of Äager

Pipeline Pigging Systems refer to the process and equipment used for the cleaning and maintenance of pipelines using a device called a pig.

Pipeline Pigging Systems refer to the process and equipment used for the cleaning and maintenance of pipelines using a device called a pig.