Surge Vessels

Crucial Part of Your Pipeline Operation Integrity; Safe, Reliable and Sustainable

ERGIL Surge Protection & Water Hammer System is a powerful and user-friendly control system that protects your pipeline against water hammer & pressure transients for potable water, sea water and wastewater applications.

Water industry is being challenged with water scarcity, increasing construction, break-down, and maintanance costs, therefore continued operation has become more important than ever.

ERGIL Surge Protection & Water Hammer System protects not only humans’ life, but also your pipeline, pump stations, hydrants, valves, and other related equipment.

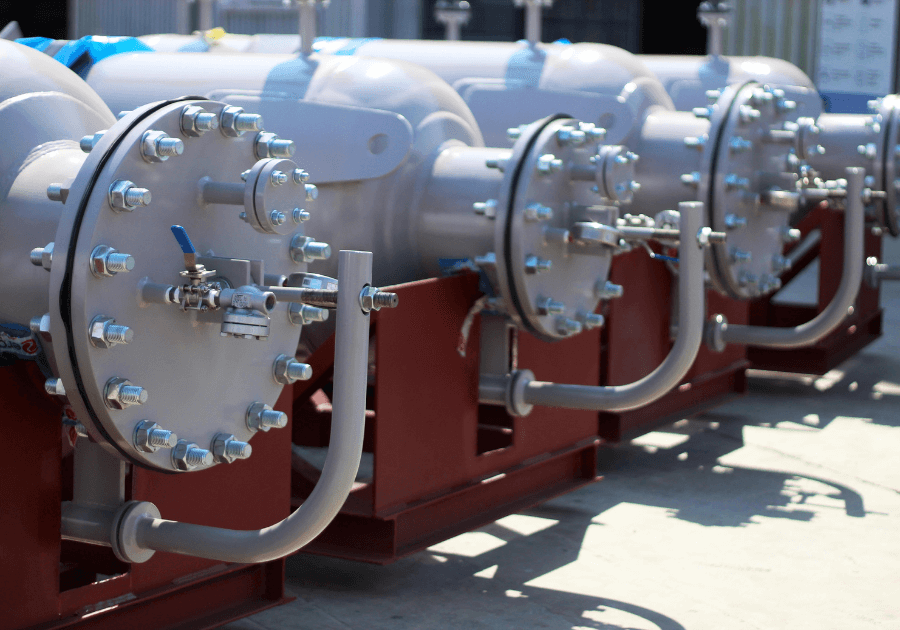

ERGIL designs and manufactures both bladder type and compressor type surge vessel systems.

Surge Vessels

Certified Pressure Vessel Manufacturer

ERGIL has been designing and fabricating engineered to order high pressure vessels since 1982. Surge vessel is the most important part of the water hammer system.

Designing and manufacturing high surge vessels requires certain specialization that has to be accredited by industrial authorities.

With more than 40 years of engineering experience and the trust of numerous successfully completed projects, we are always at your side.

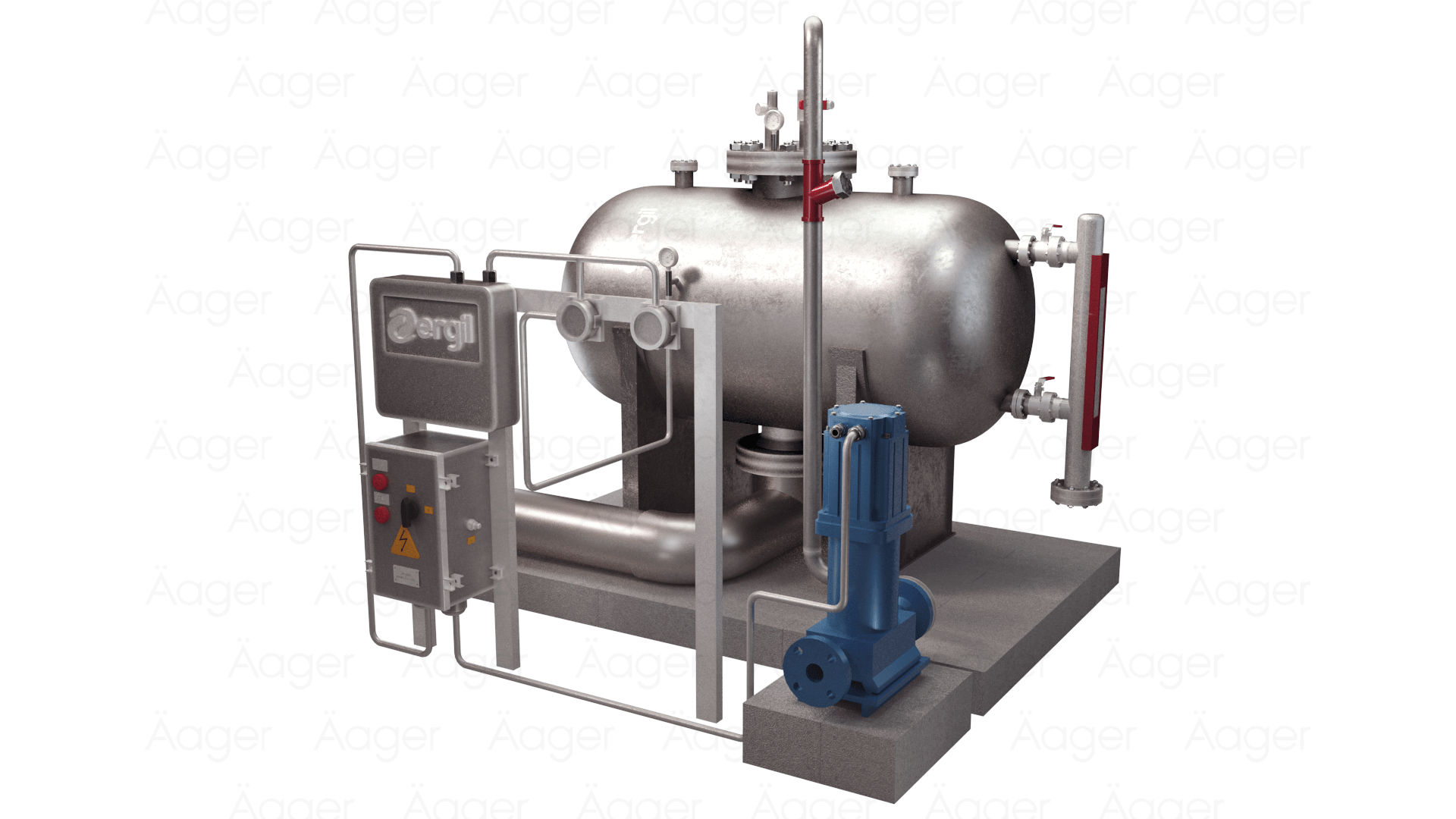

Custom-made Modular Skid Systems

Surge Vessel Body (as per ASME, EN or GOST)

Bladder (material is carefully chosen as per the requirements)

Internals; such as vortex breakers, supports, grills

Compressors & Pumps

Level Indicator

Relief Valves

Gauges

Instrumentation

Drain Valves

Control Panel

Skid Mobile or Fixed Frame & Components

Piping

Ladder & Platform

Legs

Lightning & Earthing

Best Internal Bladders

Bladders are the most critical part of any air-in & water-in surge vessels. ERGIL’s years of experience, search and development projects help to understand how and what kind of bladder vessel to use. Choosing the right bladder plays an important role for the integrity of the system. Bladders are fragile items in nature and have to be designed with extra protection. Since, it is in direct contact with the water, it effects human life; therefore we offer certified bladders for potable water (drinking water) applications.

ERGIL manufactures;

Butyl Rubber (BR),

Polyurethane (PU),

Polyvinyl Chloride (PVC) type bladders.

Upon request, we also provide WRAS (UK Water Regulations Advisory Scheme) & Non-Toxic Certificate.

Compact Design

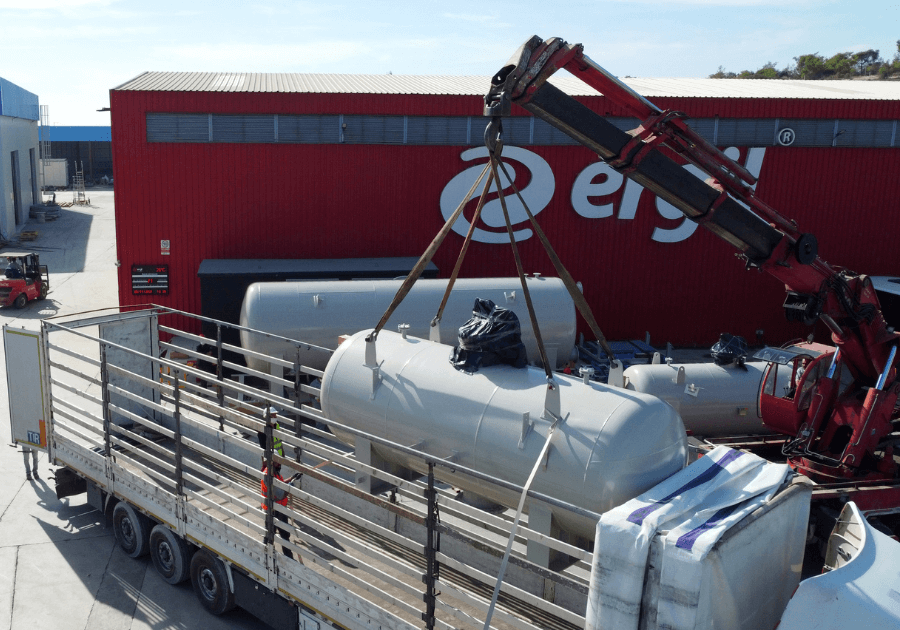

ERGIL’s compact skid bladder & compressor type vessels provide all you need on a single skid. ERGIL designs mobile or permanent frames, so moving from one place to another and using it for multiple pipelines is possible.

They are easy to transport from one location to another. Modules can be designed as per the shipping method (sea, road and even air) and the system can be customizable as per working environment to protect against rush weather effects or robbery.

Traditional surge vessel system contraction is costly, takes time, and safety concerns are high, however ERGIL’s mobile modular surge plug and play systems can reduce your project cost and time drastically in addition to eliminating site accidents. Contractors do not need to deal with site installation of such complicated.

Features

- Renowned company understanding of surge system design

- Ensures compliance with Product Equipment Directive & ASME regulations

- Reduces water leakage

- Pipeline fatigue and bursts analyze

- Minimizes risk of contamination in potable water pipes caused by negative pressures

- Accommodates variable pumping regimes without dumping compressed air

- Improves your company’s environmental social responsibility and public image

- Vertical or horizontal types are available

- The bladder is designed so it can expand to the full size of the vessel. This allows for greater drawdown volumes and less stress on the bladder.

- The air is trapped in the space between the outside of the bladder and the wall of the vessel. Therefore the liquid is not in contact with the steel walls of the vessel.

- Depending on the level of cubage in the tank it is possible to design by using minimum 3, maximum 4 legs as optional

- Design code: ASME and others

Request A Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon

Projects

Discover Our Global Success Stories: Join the Journey of Inspiration!

News, Events & Case Studies

Dive into a World of Knowledge and Insight: Explore Our News, Events, Articles, and Case Studies!

Surge Vessels FAQ's

Find Out More About Us

Our people are our biggest asset but the only way to unlock their potential is to invest in the right business systems that encourage innovation.

40+ Years in Business

40+ Years in Business More than 40 years of experience

Easily Reachable

Worldwide Offices and Representatives

Superior After Sales Support

Long-term business partnerships

Certifications ATEX, ASME, ISO, CE

High-end Production Facility

35,000 square meter manufacturing facility

Being leader in manufacturing better, safer, and economical products

Contribute positively to our communities and environments well as to ensure highest level of customer satisfaction through the highest standards of excellence in our products and services, and comprehensive environmental regulations. Working everyday for the creation of better products that protects environment, people and assets.

Our history begins in 1938 and goes on together with all our parties.

- 1983 - Founded

- 1987 - Added 100. product to its portfolio

- 1991 - Certified products and services

- 2005 - Opened its first international office

- 2010 - Became market leader in 11 countries

- 2010 - Invested heavily in new manufacturing facility

- 2015 - Build one of the biggest R&D in its-field

- 2018 - Became part of Äager