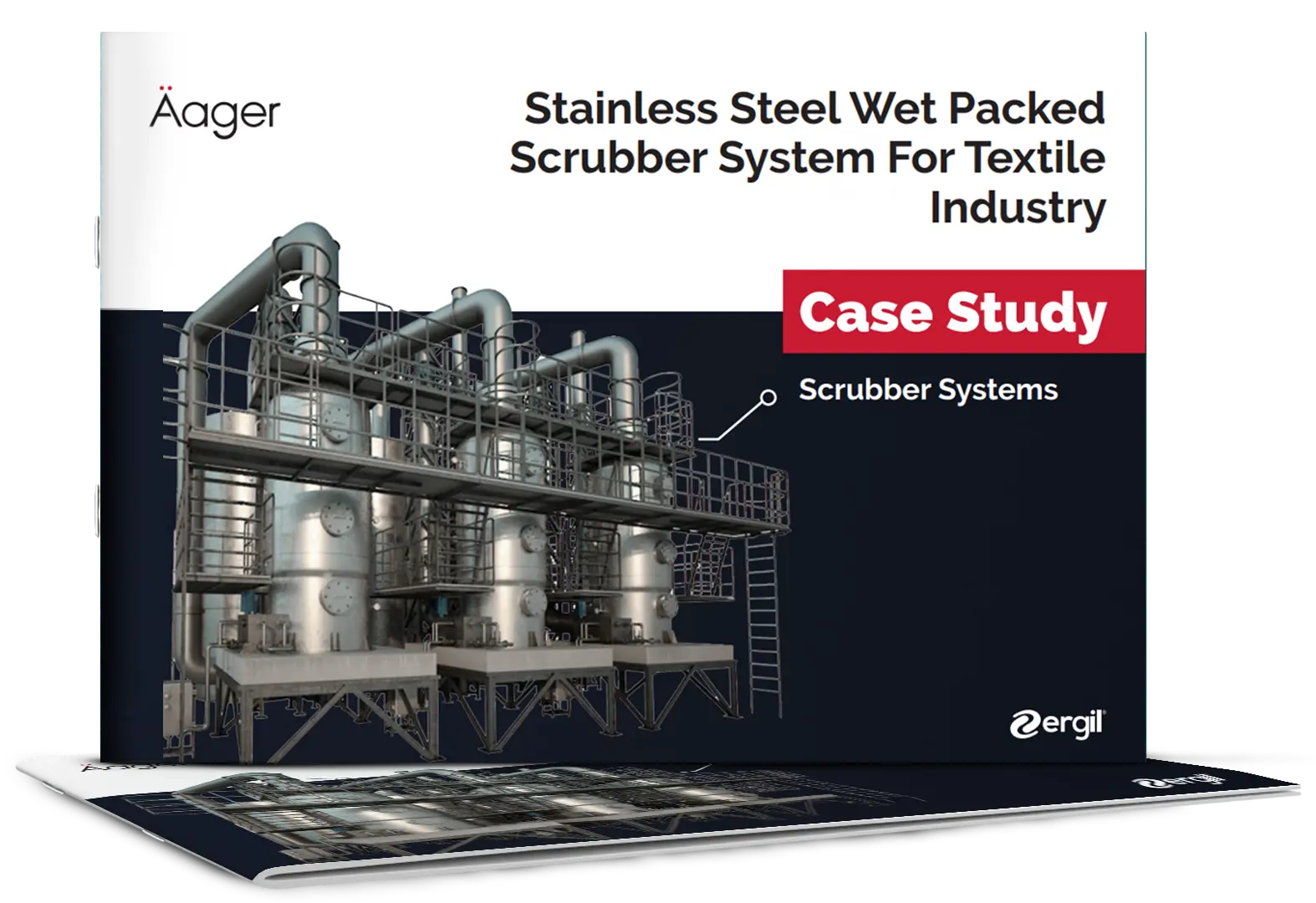

Stainless Steel Wet Packed Scrubber System For Textile Industry

Chemicals with high corrosion risk provide cleaning up to 99%

Project Overview and Challenge

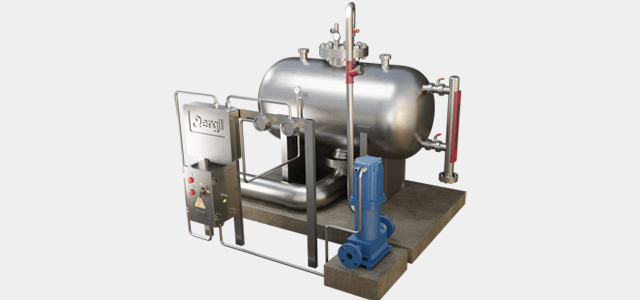

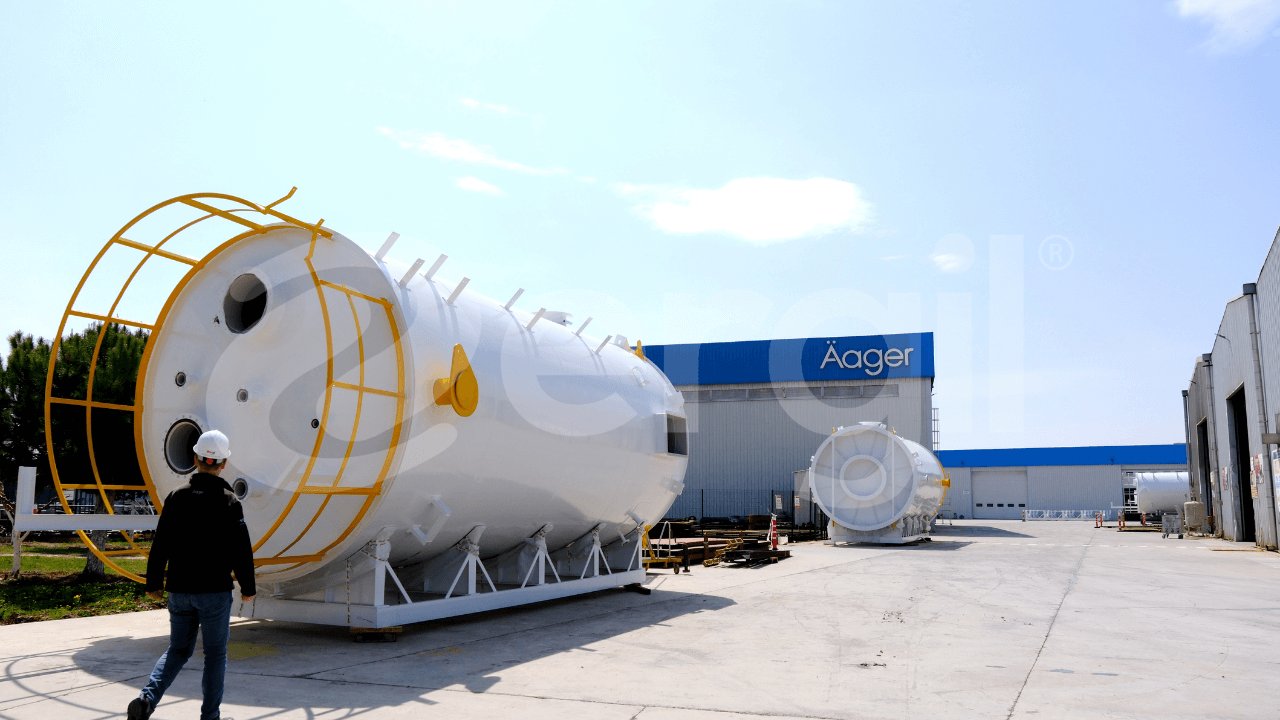

The most important factor in preventing environmental pollution is minimizing the environmental damage caused by industrial activities. For this purpose, Ergil, an Aager brand, has successfully designed, engineered and manufactured a wet-filled gas scrubbing system, one of the emission control

devices.

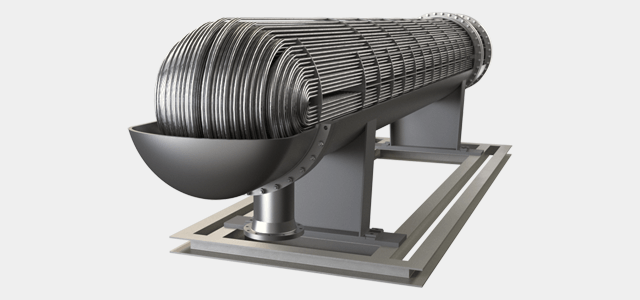

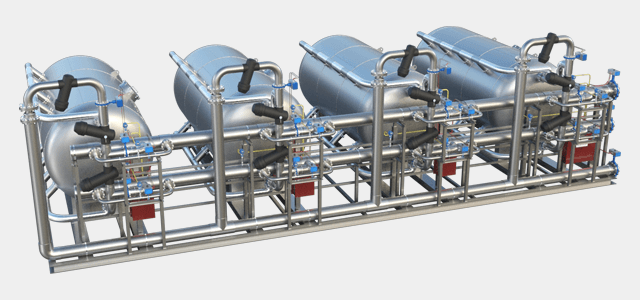

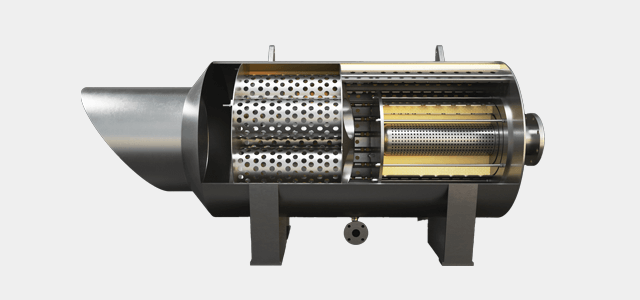

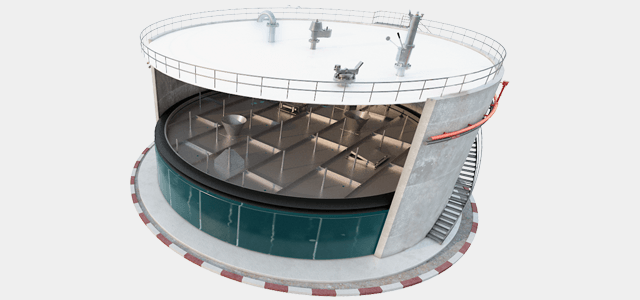

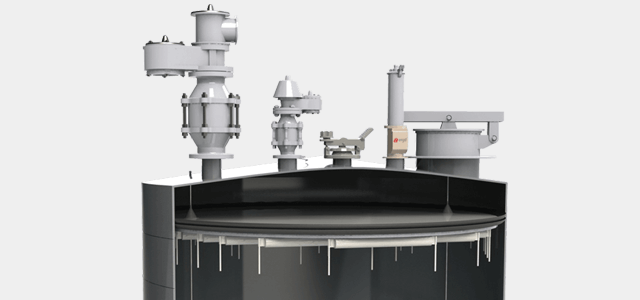

Wet-filled gas scrubbing systems are one of the effective emission control devices used to remove soot, dust, chemical vapor, odor and aerosol pollutants formed as a result of the activities of industrial facilities. The system consists of a cylindrical tower filled with fillers to provide time and contact area for the incoming pollutant gas and cleaning solution to chemically react. The cleaning solution sprayed from the nozzles placed at the top of the tower wets the pollutant gas entering the tower from under the filling materials, eliminating the toxic and corrosive properties of the gas. The main components of the system; It consists of circulation pump, filling materials, drip trap and spray nozzles.

In this case, the pollution rate of SO2 gas originating from the starch processing process at 500 ppm, 50°C and 2300 m3/h flow rate; It is requested

to reduce the emission values to the atmosphere determined by the legal regulations requested by the customer.