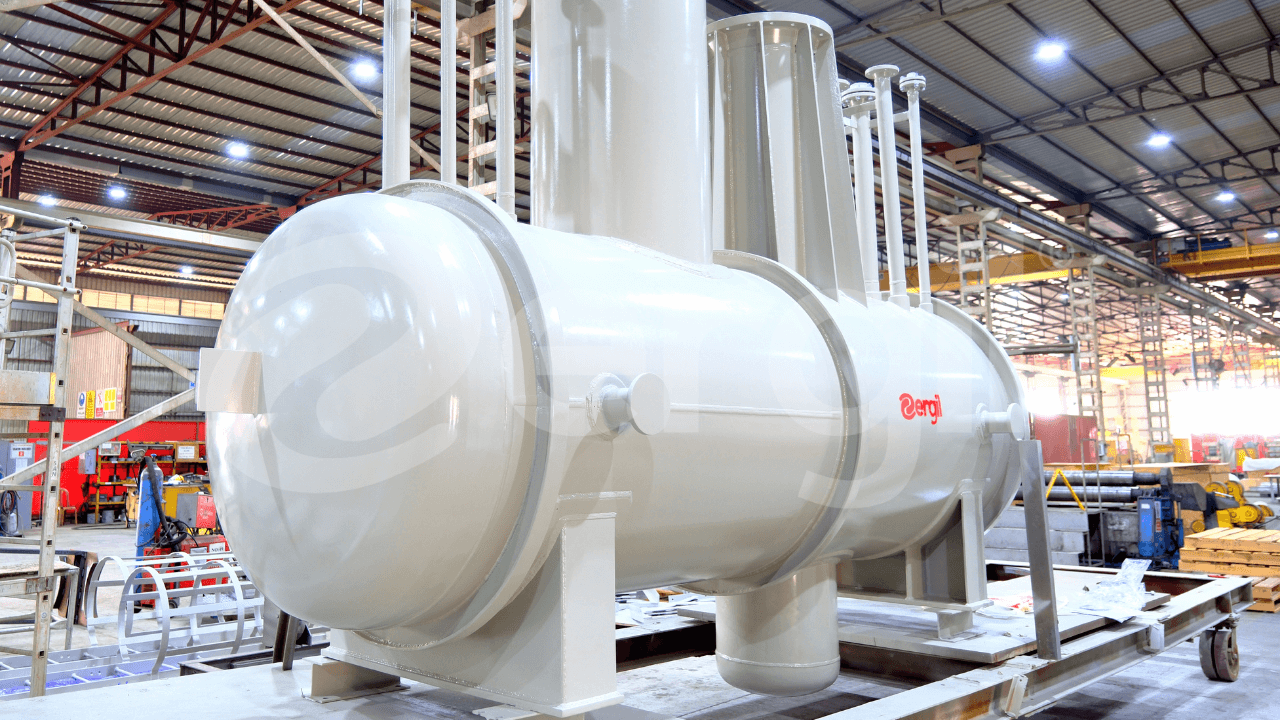

Closed Drain Drum for LUKOIL Uzbekistan – How It Adds Value to the Process

A Closed Drain Drum is more than a storage cylinder; it is the safety buffer between routine liquid drains and the rest of your facility. During start-ups, pigging, blow-downs or equipment isolation, liquids can flash, foam or carry H₂S. The drum receives this unpredictable flow, equalises pressure and temperature, and lets operators route the liquid to a flare or treatment system under full control.

Where It Fits in the Kandym Plant

- Collects liquids from pumps, compressors, separators and small-bore drains.

- Quenches flash vapour so gas can be sent to flare with low liquid carry-over.

- Allows safe sampling and truck-out when required, reducing environmental discharge.

Process Benefits

- Reduced vent loading – flash gas disengages inside the drum, keeping flare headers smaller.

- Cleaner maintenance windows – operators drain lines to a single, sealed location, cutting down spills.

- Long service life – duplex nozzles plus HIC-tested shell fend off sulphide stress cracking in sour service.

- Regulatory confidence – U-stamp and NACE compliance simplify authority approvals.

Why Ergil?

- Integrated scope – design, fabrication, inspection and FCA packing under one roof minimises interface risk.

- Field-proven – hundreds of drain drums in service across refineries and gas plants worldwide.

- After-sales support – spares, inspection guidance and retrofit options for evolving process needs.

For technical datasheets, drawings or a fast quotation, contact the Ergil Process Equipment team.

Ergil, delivering excellence in industrial solutions.

Details

A Closed Drain Drum is more than a storage cylinder; it is the safety buffer between routine liquid drains and the rest of your facility.