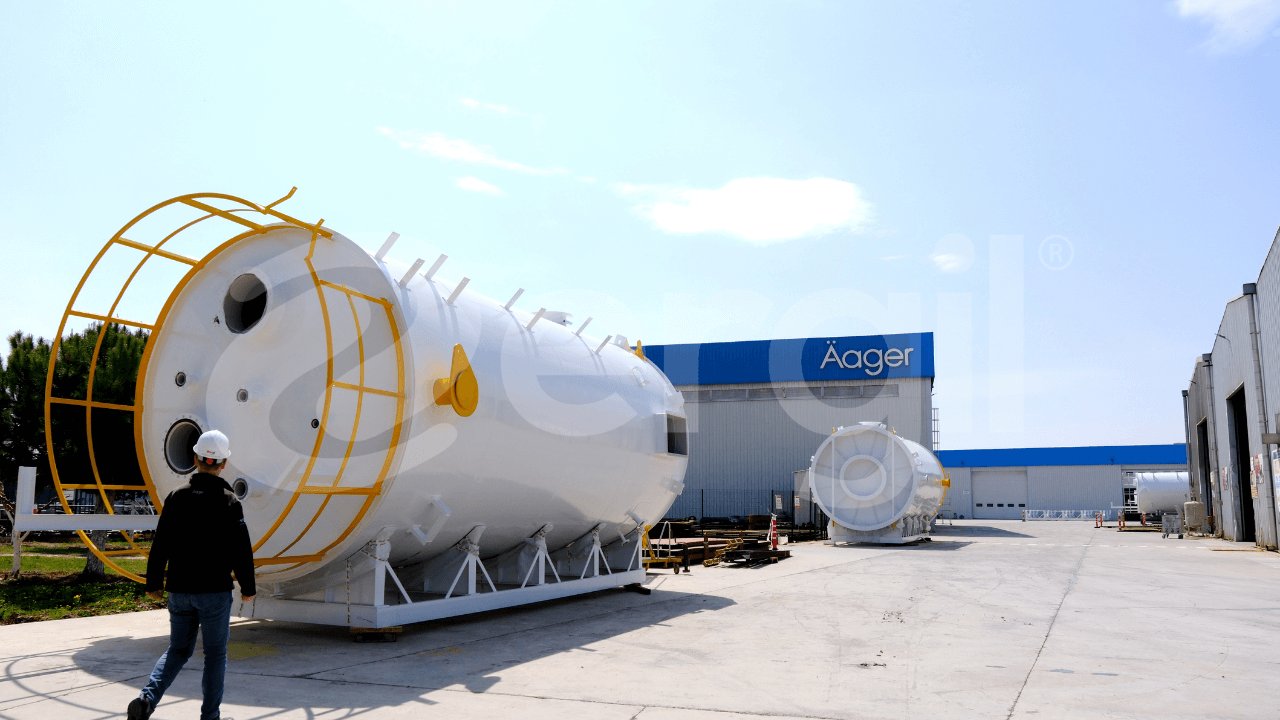

Esta Construction The Midia Gas Development Project (MGD Project)

Project Overview and Challenge:

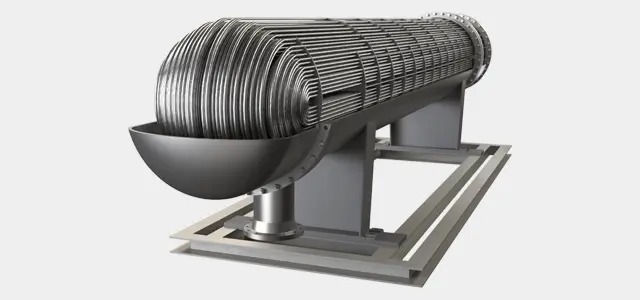

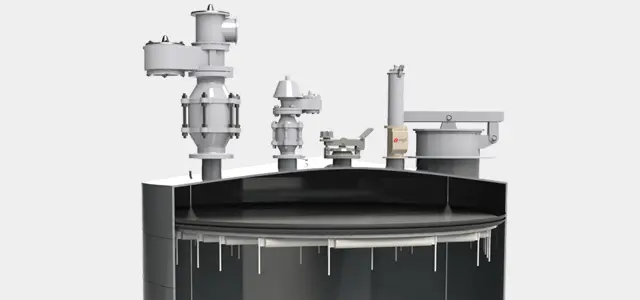

The Midia Gas Development Project basically covers the extraction of the gas from the depth of the sea, transferring it to the land (on-shore) and processing it. As an Äager Brand ERGIL, we took place at the stages of processing, mechanical design and fabrication for the erection of the various storage tanks, pressure vessels and domestic equipment for the Gas Treatment Plant (Early gas production facility). This plant is used to treating the extracted gas and converting it into utilizable material.

In terms of reservoirs, the Midia Gas Development project (MGD project) consists of the Ana and Doina gas fields (roughly 300 Bcf P50 reserves) which were discovered in 2007 and 1995 respectively. Both are of latest Miocene to Dacian age, shallow, marine sandstone (delta-tops), biogenic gas reservoirs, some 120 km offshore Romania, in the XV Midia Shallow area where the water depths are of 70 meters.