Introduction:

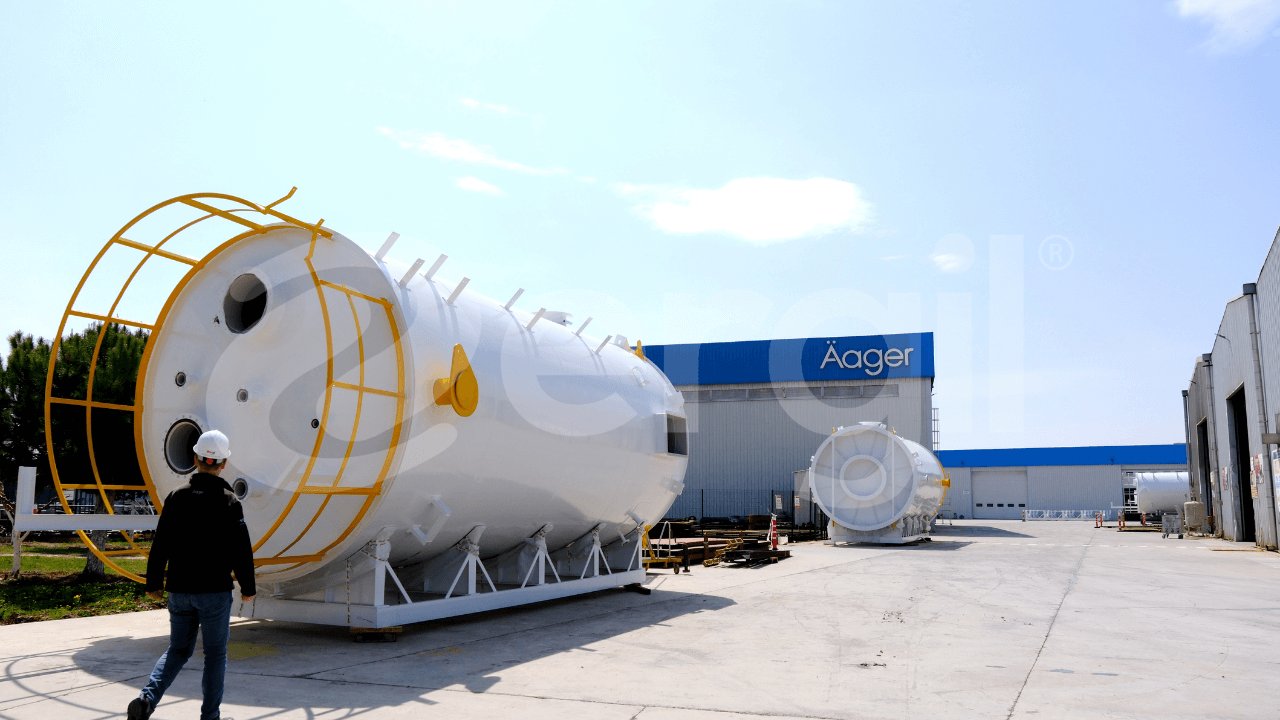

Pigging operations play a crucial role in the maintenance and optimization of pipeline systems within the oil and gas industry. Pig launcher and receiver (L&R) systems are essential components used for the deployment and retrieval of pipeline pigs, specialized devices employed for cleaning, inspecting, and maintaining pipelines. This article will delve into the crucial technical parameters for designing pig launcher and receiver systems, ensuring efficient and reliable pipeline operations.

Design code

Main body design

Since the pigging station and pig traps are pressure vessel it can be designed as pressure vessel according to international standard which is ASME Section VIII Div.However, subsequently, the pipelines connected to the pig traps are designed according to the pipeline design rules, various incompatibilities arise due to different material classes, design factors and MAWP, and mainly the thickness of the barrels will be calculated differently from the pipeline thickness. This is a common problem, and the main design requirement for the pig trap small barrel ID should be the same as the ID of the pipeline.

The most appropriate code for the pig traps is usually the same design code as the pipeline:

- ASME B31.3 (code) (USA): regulates the design of process piping

- ASME B31.4 (code) (USA): governs the design of liquid pipelines

- ASME B31.8 (code) (USA): regulates the design of gas pipelines

- ISO 13623:2009 (standard): regulates Petroleum and natural gas industries – Pipeline transport systems

- BS EN 14161:2011(standard) (Europe): regulates Petroleum and natural gas industries – Pipeline transport systems (MODED version of ISO 13623:2009)

- ISO 13703:2000 (standard): regulates Petroleum and natural gas industries – design and installation of piping systems on offshore production platforms

Also other pipeline design codes not listed above

– Quick opening closure design

The quick opening closure should be design according ASME Section VIII Div. 1 Or 2 and ASME UG-35 must be completely followed for safety operations.

Design Pressure and Temperature:

The design pressure and temperature parameters are critical in determining the structural integrity and safety of pig launcher and receiver system. Scientific studies have shown that pipeline systems are subjected to various pressures and temperatures. These parameters should be carefully chosen based on the pipeline’s maximum operating pressure (MOP) and temperature, taking into account safety margins and regulatory requirements. Proper selection of design pressure and temperature helps ensure that the L&R system can withstand the pipeline’s operating conditions without risking system failure or compromising safety.

Pig trap components to be considered on the design

- Connection to the pipe line: Either it can be specified as welded or flanged ( main connection flange )

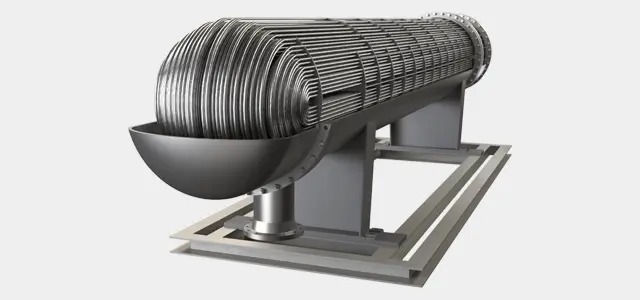

- Main Barrel: Consist of minor barrel, reducer and major barrel

- Quick opening closure: Located on end of major barrel for removing the pig Into / Out to the Pig Traps

- Branch connection ( connection nozzles ): Kicker, Bypass, Balance, Purge, PSV connections, vents and drains, Pig signaller, pressure& temperature gauging connections

- Saddles and supports

1. Connection to the pipe line:

Two types of connections can be designed;

- Welded, the main design consideration is ID of minor barrel shall have same ID of pipe line as explained

- Flange connections, connection flange rating and Norms must be same with considering equal ID of flanges

2. Main Barrel

Consist of minor barrel, reducer and major barrel.

Consist of minor barrel, reducer and major barrel.

The pipeline diameter and wall thickness are crucial factors in determining the appropriate size and configuration of the pig launcher and receiver system. These parameters affect the pig’s size, which, in turn, impacts its ability to traverse the pipeline and perform its intended tasks effectively. The L&R system should be designed to accommodate pigs with sufficient clearance to avoid jamming or damage to the pipeline or pigging equipment.

The minor barrel size should be equal to connection pipe line ID to prevent damage of pig tool during launching and receiving.

For the major barrel sizing common engineering practices specify for pipe lines smaller than 20 inch the major barrel oversized 2 inches and for pipe liens over 20” the major barrel shall be 4 inches oversized. This practice not release the designer to consider and calculate special process conditions as calculation of expected sludge volume will be collected from pipe line and removed by the pigging operation and follow and operation& process conditions more ever for pie line size with different actual size as 12” ( the actual size is 12,75 inch )

The pig trap length also to be designed considering the process & operation parameters, the most impertinent to be considered by designer the maximum pig tool length will be used in general we can consider.

-For launcher

The minor barrel length to be equal to ½ maximum pig tool lengths

The major barrel Length to to be equal to maximum pig tool length

-For Receiver

The minor barrel length to be equal to ½ maximum pig tool length

The major barrel Length to to be equal to maximum pig tool length

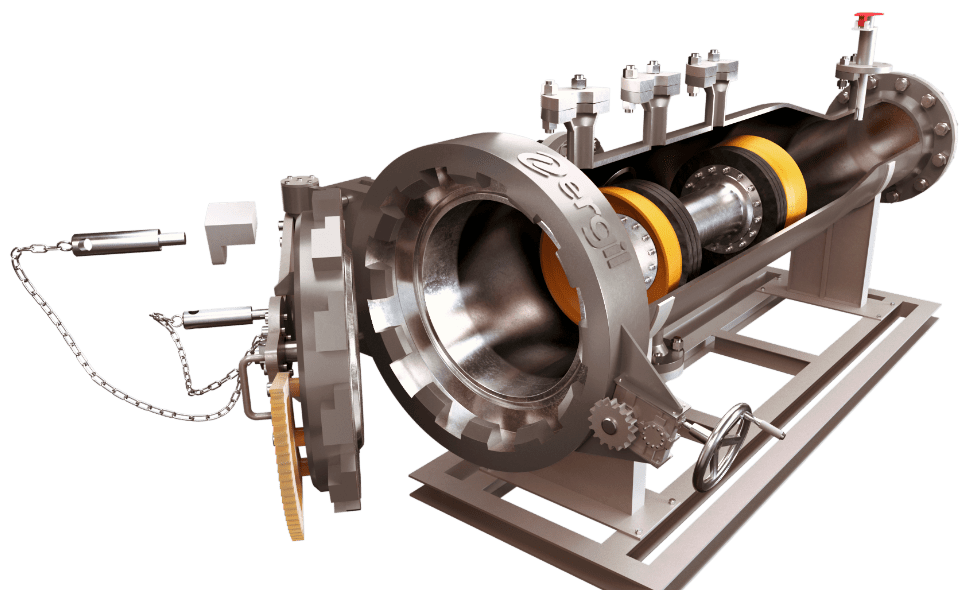

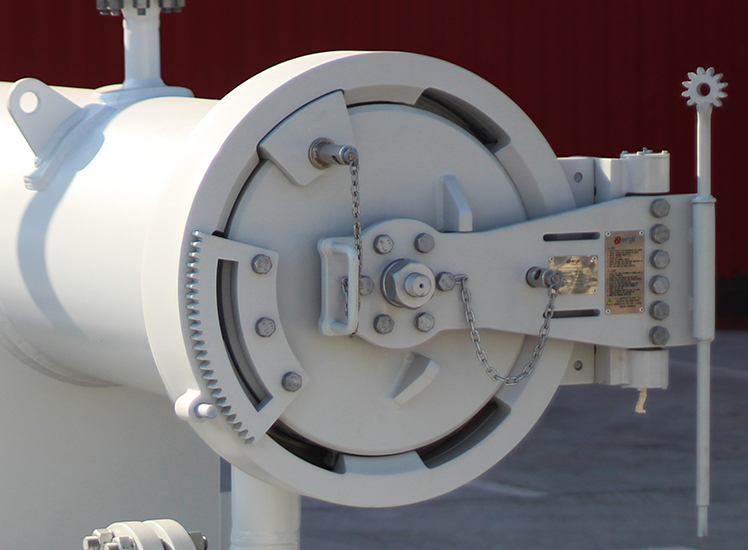

3. Quick opening closure

The pig launcher and receiver system’s closure type is a critical design consideration, as it affects the ease of operation, safety and maintenance. Common closure types include quick-opening closures, threaded closures and bolted flange closures. The chosen closure type should provide a reliable seal, be user-friendly and meet the necessary safety and operational requirements.

The pig launcher and receiver system’s closure type is a critical design consideration, as it affects the ease of operation, safety and maintenance. Common closure types include quick-opening closures, threaded closures and bolted flange closures. The chosen closure type should provide a reliable seal, be user-friendly and meet the necessary safety and operational requirements.

Located on end of major barrel for removing the pig Into / Out to the Pig traps. Main requirements of design codes and safety operation requirements like below;

- The closure must be equipped with two main mechanical interlocking system to prevent opening the closure while its under pressure

- Quick acting closure ( closing , opening

- Operated by single operator

- Full bore on opening position

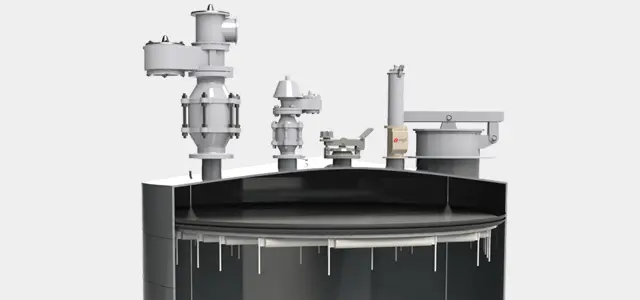

4. Branch connections ( connection nozzles )

Kicker, Bypass, Balance, Purge, PSV connections , vents and drains , pressure& temperature gauging connections

A well-designed branch connections and nozzles essential for the safe and efficient operation of the pig launcher and receiver. The system should allow controlled venting of pressure and fluid to ensure safe pig insertion and retrieval. The bypass system should also facilitate smooth flow diversion, minimizing pressure surges and potential damage to the pipeline or pigging equipment.

The size and location of the branch connections should be designed considering the process and operation for pigging station with P&ID.

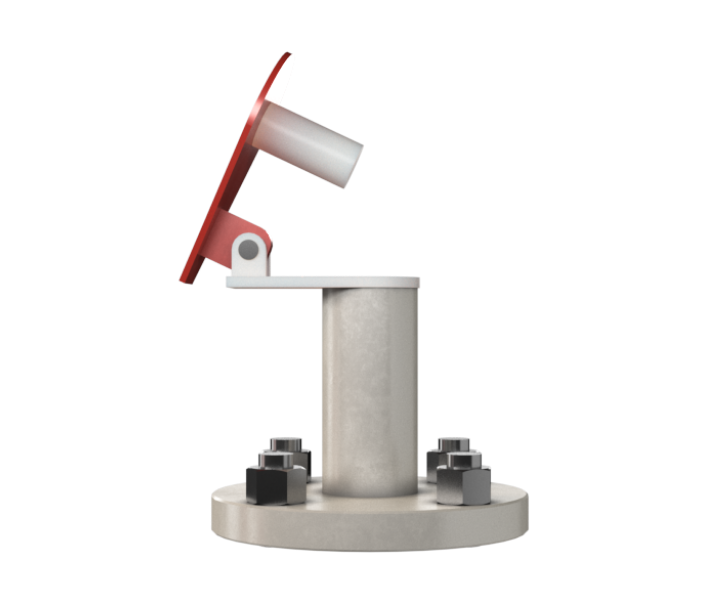

5. Pig signaller

Advice used for indicating the pig passing throw the located points for pig launcher shall be located on end of minor barrel ( connection point to pipe line , for receiver connection point to reducer )

Advice used for indicating the pig passing throw the located points for pig launcher shall be located on end of minor barrel ( connection point to pipe line , for receiver connection point to reducer )

Pig Type and Function:

The pig’s specific type and function must be considered when designing a pig launcher and receiver system. There are various types of pigs, including utility pigs (for cleaning and debris removal), inline inspection (ILI) pigs (for assessing pipeline integrity), and specialty pigs (for specific tasks such as sealing or batching). The L&R system should be designed to accommodate the particular pig type and its function to ensure optimal performance and efficiency.

The main pig tools categorized according the their function:

- inspection

- maintenance and repair

- renovationhehabilitation

- Decommissioning

Safety Features:

Scientific studies have highlighted the importance of incorporating comprehensive safety features into pig launcher and receiver systems. Safety features, such as pressure relief devices, interlocks, and emergency shutdown systems, should be incorporated into the pig launcher and receiver design. These features help protect operators and equipment from potential hazards associated with pigging operations, such as overpressure, pig jamming, or accidental release of pipeline contents.

Conclusion:

Designing a pig launcher and receiver system requires careful consideration of various parameters to ensure efficient, reliable, and safe pipeline operations. By taking into account factors such as design pressure and temperature, pipeline diameter, pig type and function, barrel length, closure type, bypass and venting system, and safety features, engineers can develop a robust and effective pig L&R system tailored to specific pipeline requirements.