Modular Systems Fabrication

Modular Fabrication Services Across Industries

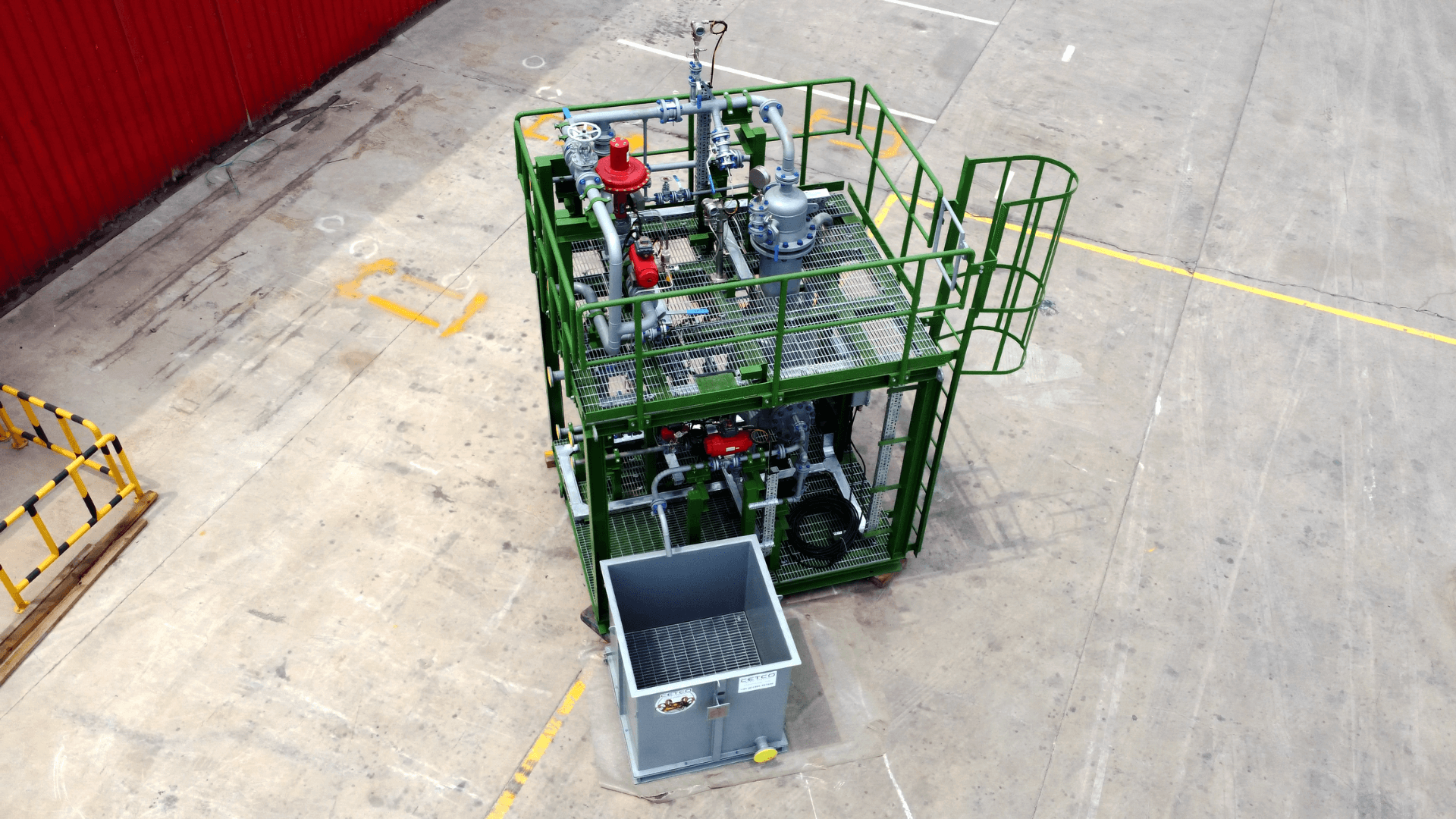

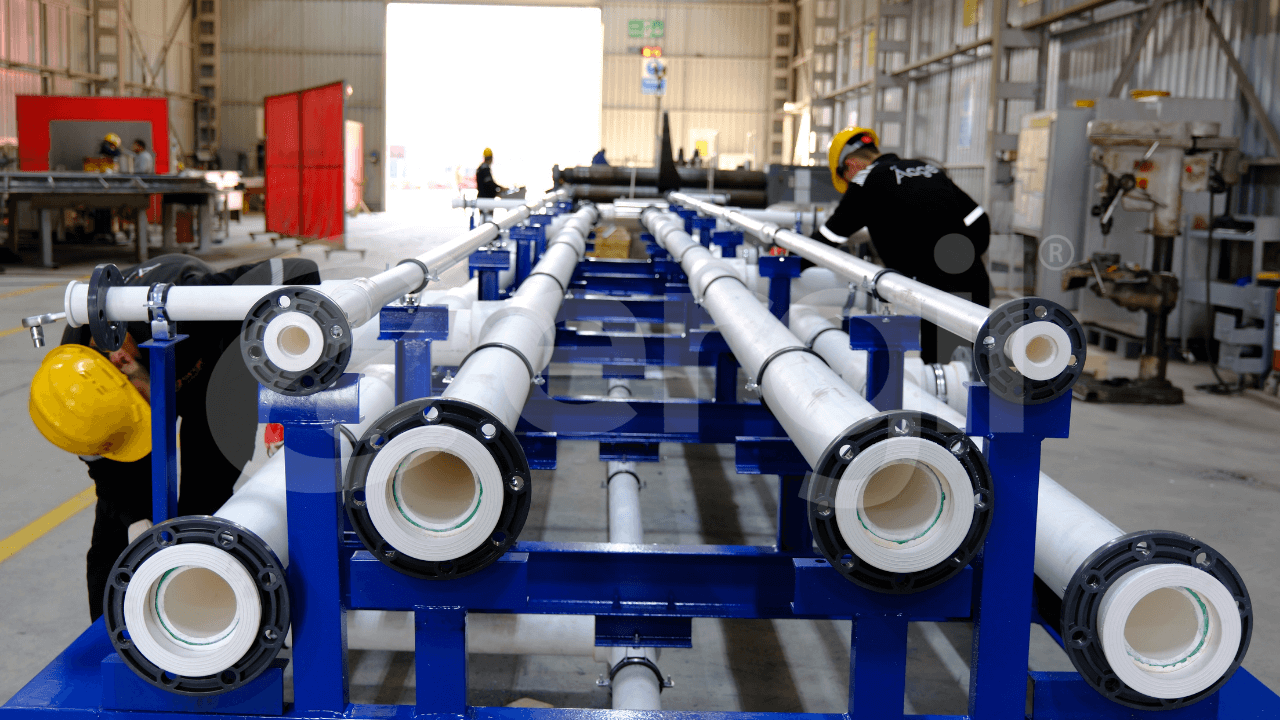

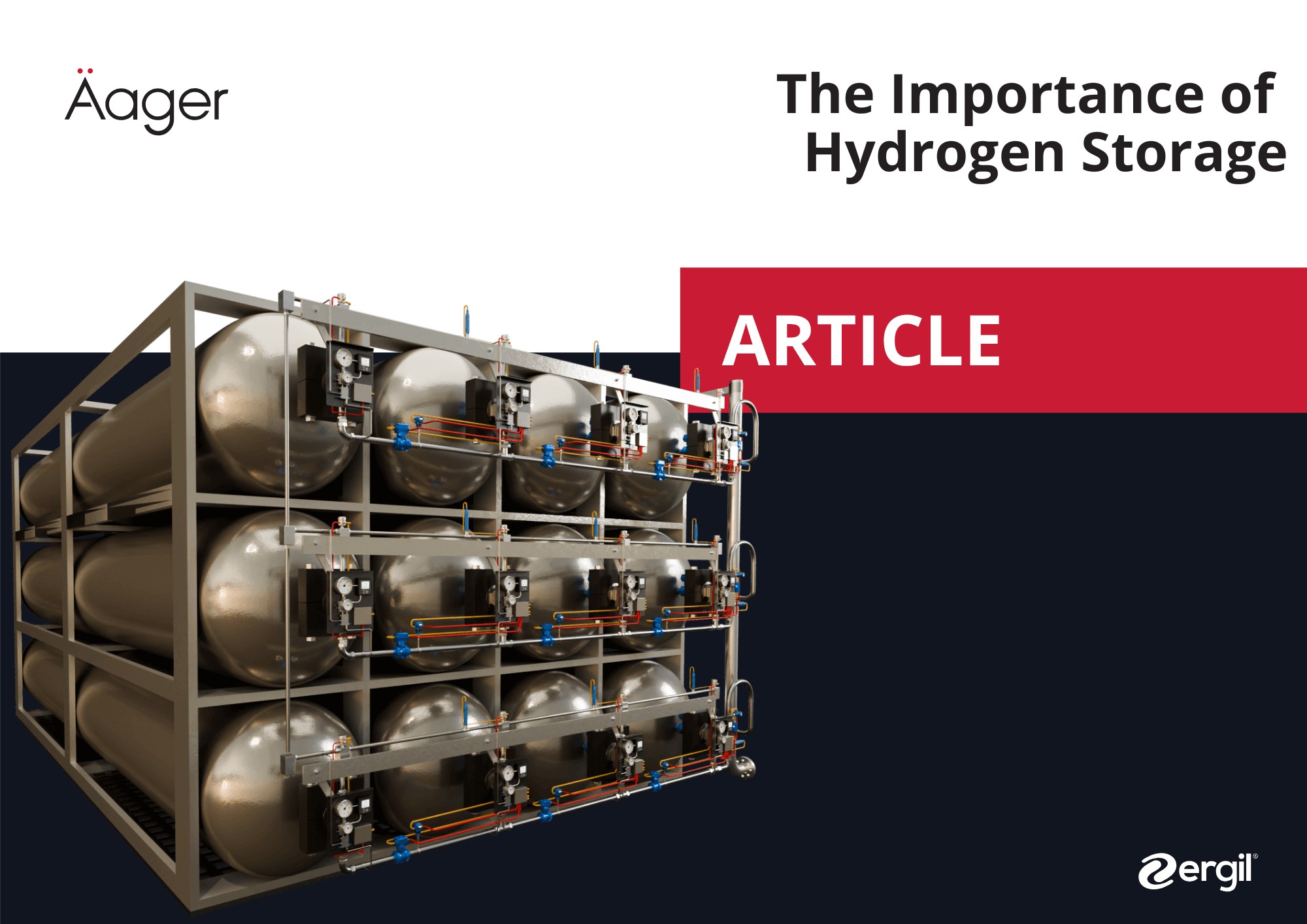

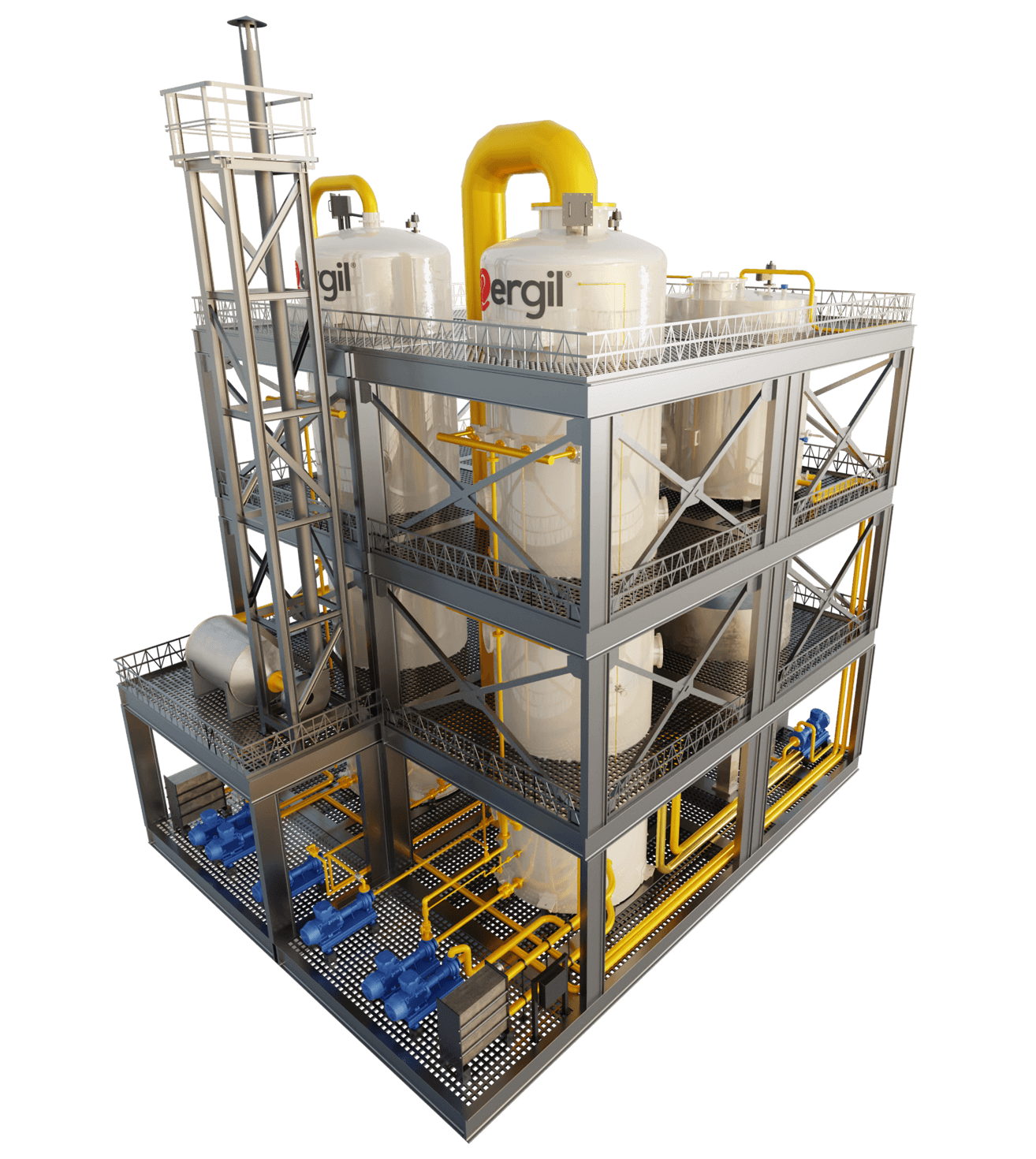

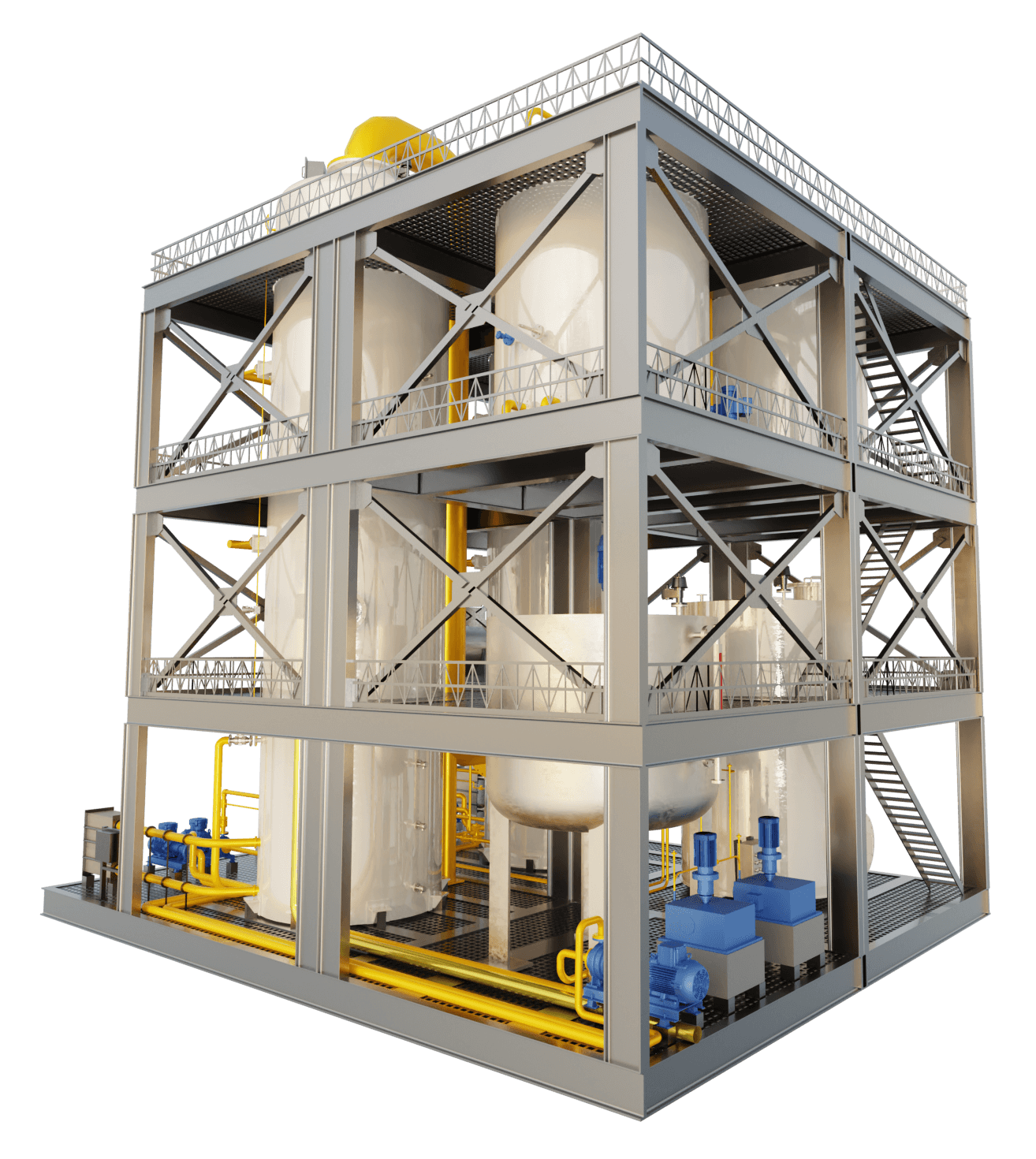

ERGIL provides modular fabrication solutions for OEMs, technology providers, and engineering contractors across a wide range of industries. We specialize in the manufacturing of fully assembled, skid-mounted, and containerized systems that integrate mechanical, piping, structural, and instrumentation components.

Modular Piping & Process Structures

Pre-engineered systems for integrated fluid handling and plant-wide connectivity

Capabilities

Application Areas

Serving industries such as oil & gas, chemical, energy, circular economy, industrial manufacturing, water treatment, and environmental technology.

ERGIL supports modular system fabrication across a wide range of process applications, including but not limited to:

Our Modular Project Execution Model

Request A Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon

Why Modularization with ERGIL?

ERGIL’s modular fabrication services are designed to streamline project execution and improve quality. Compared to conventional stick-built construction, our modular approach offers:

- Accelerated project timelines through parallel fabrication and site preparation

- Reduced total installed cost by minimizing field labor and rework

- Improved quality control under factory conditions

- Lower site risk and disruption, ideal for complex or remote locations

- Repeatability and scalability for clients operating across multiple regions

Our team works closely with EPCs and technology providers to ensure modules are fully integrated, tested, and delivered according to the project’s timeline and technical requirements.

Our Modular Project Execution Model

- Scope Alignment & Proposal – Review of process requirements, deliverables, and boundaries

- Design Interface & Procurement – Coordination with client engineering, procurement of materials

- Fabrication & Assembly – Modular construction including mechanical, piping, and electrical work

- Testing & FAT – Hydro/pneumatic testing, functional testing, and documentation

- Installation & Commissioning Support – Supervision, startup, and on-site verification services

This structured approach ensures predictable delivery, cost control, and consistent quality.

Projects

Discover Our Global Success Stories: Join the Journey of Inspiration!

News, Events & Case Studies

Dive into a World of Knowledge and Insight: Explore Our News, Events, Articles, and Case Studies!

System FAQ's

Find Out More About Us

Our people are our biggest asset but the only way to unlock their potential is to invest in the right business systems that encourage innovation.

More than 40 years of experience

Easily Reachable

Worldwide Offices and Representatives

Superior After Sales Support

Long-term business partnerships

Certifications ATEX, ASME, ISO, CE

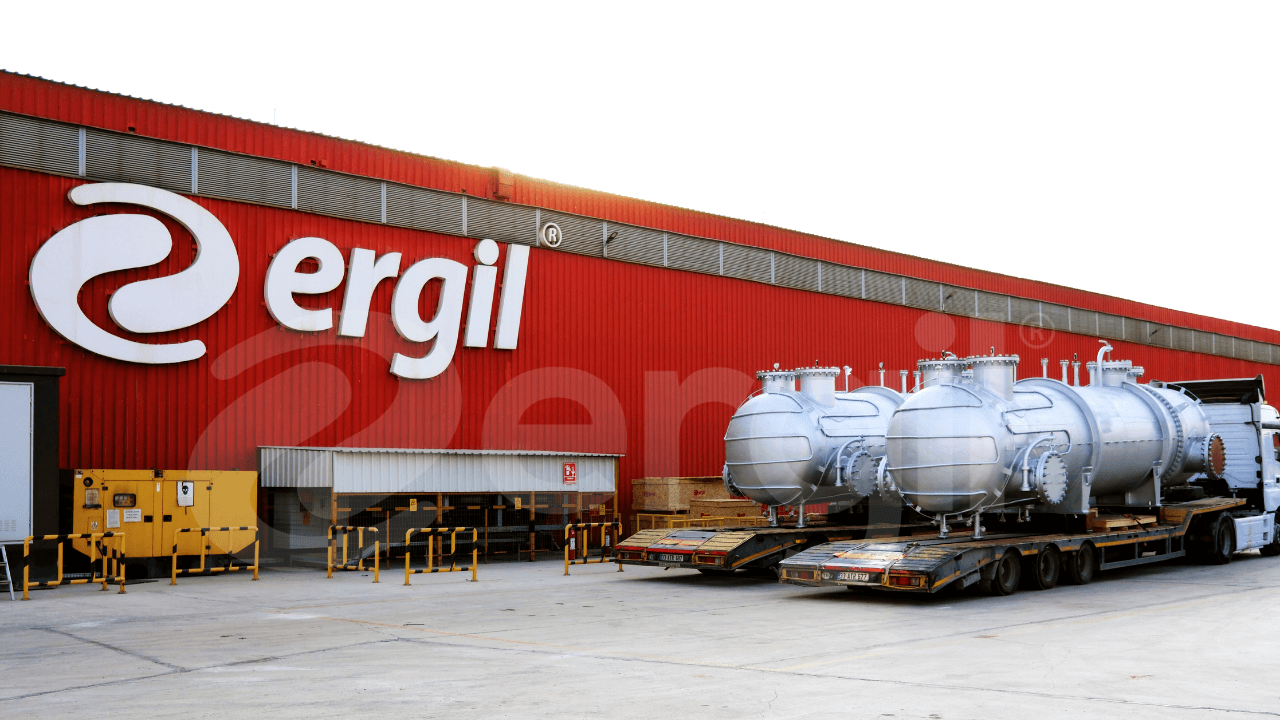

High-end Production Facility

35,000 square meter manufacturing facility

Being leader in manufacturing better, safer, and economical products

Contribute positively to our communities and environments well as to ensure highest level of customer satisfaction through the highest standards of excellence in our products and services, and comprehensive environmental regulations. Working everyday for the creation of better products that protects environment, people and assets.

Our history begins in 1938 and goes on together with all our parties.

- 1983 – Founded

- 1987 – Added 100. product to its portfolio

- 1991 – Certified products and services

- 2005 – Opened its first international office

- 2010 – Became market leader in 11 countries

- 2010 – Invested heavily in new manufacturing facility

- 2015 – Build one of the biggest R&D in its-field

- 2018 – Became part of Äager