Problem

Industrial CO₂ emissions are one of today’s biggest global challenges. Companies face strict regulations, rising carbon costs, and social pressure.

Current capture systems are costly, slow to deploy, and difficult to scale leaving industries without practical solutions.

Solution

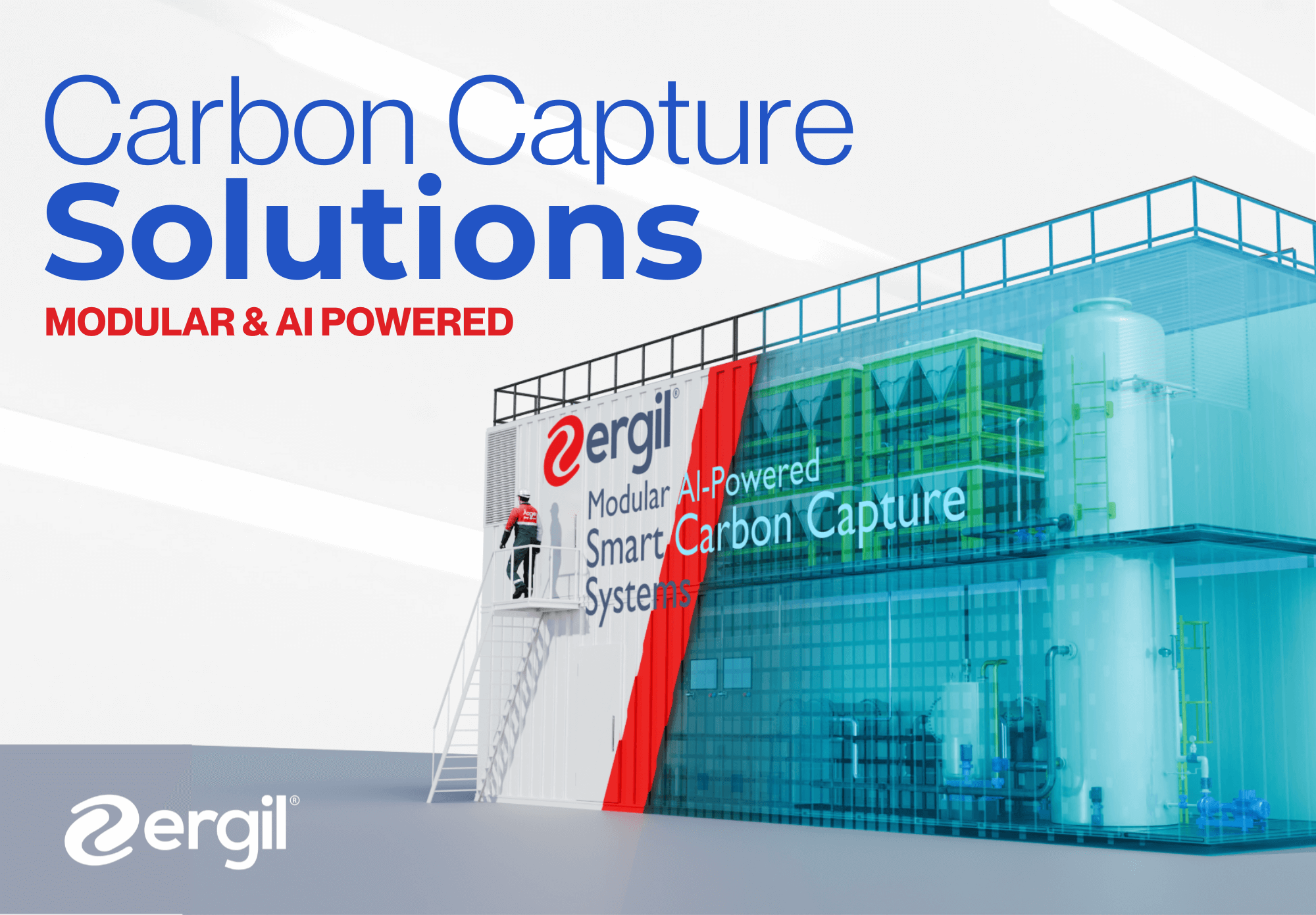

We deliver a Smart, Modular, AI-powered Carbon Capture System that directly addresses the inefficiencies of current technologies.

Our solution is cost-effective, energy-efficient, and scalable, enabling industries to cut emissions while improving ROI and compliance.

Smart Carbon Capture, Powered by Experience & AI

ERGIL combines 40+ years of scrubber expertise with next-generation AI-powered carbon capture technologies.

Proven Emission Control

Our scrubber systems have long been trusted to control H₂S, NH₃, SOₓ, NOₓ, VOCs, and particulate emissions across multiple industries.

Next-Gen CCS Technology

AI-driven algorithms instantly adapt to flue gas variables—composition, temperature, pressure, pH, and energy—ensuring stable CO₂ capture and reduced energy use.

Efficiency & Sustainability

Modified amine-based solvents with AI-optimized regeneration deliver high selectivity, lower OPEX, and extended solvent life. ERGIL CCS achieves higher capture rates with less energy.

Towards Net-Zero

When powered by renewables, our systems can even deliver negative emissions, eliminating the carbon footprint.

Comprehensive Solutions

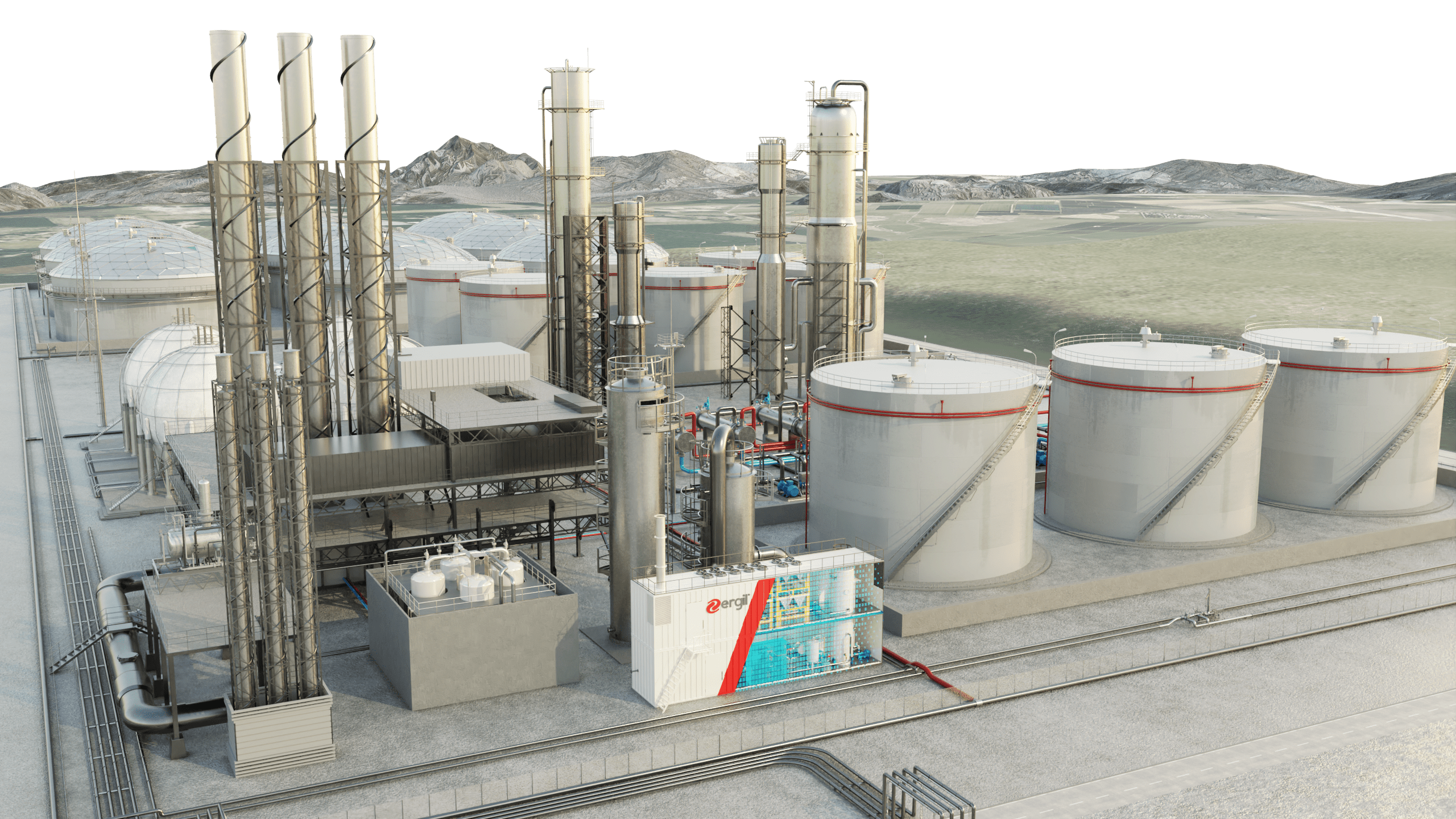

By integrating scrubber and CCS technologies, ERGIL provides turnkey solutions for air pollution control and greenhouse gas reduction in cement, steel, power, and chemical industries.

Carbon Capture

Process Chain

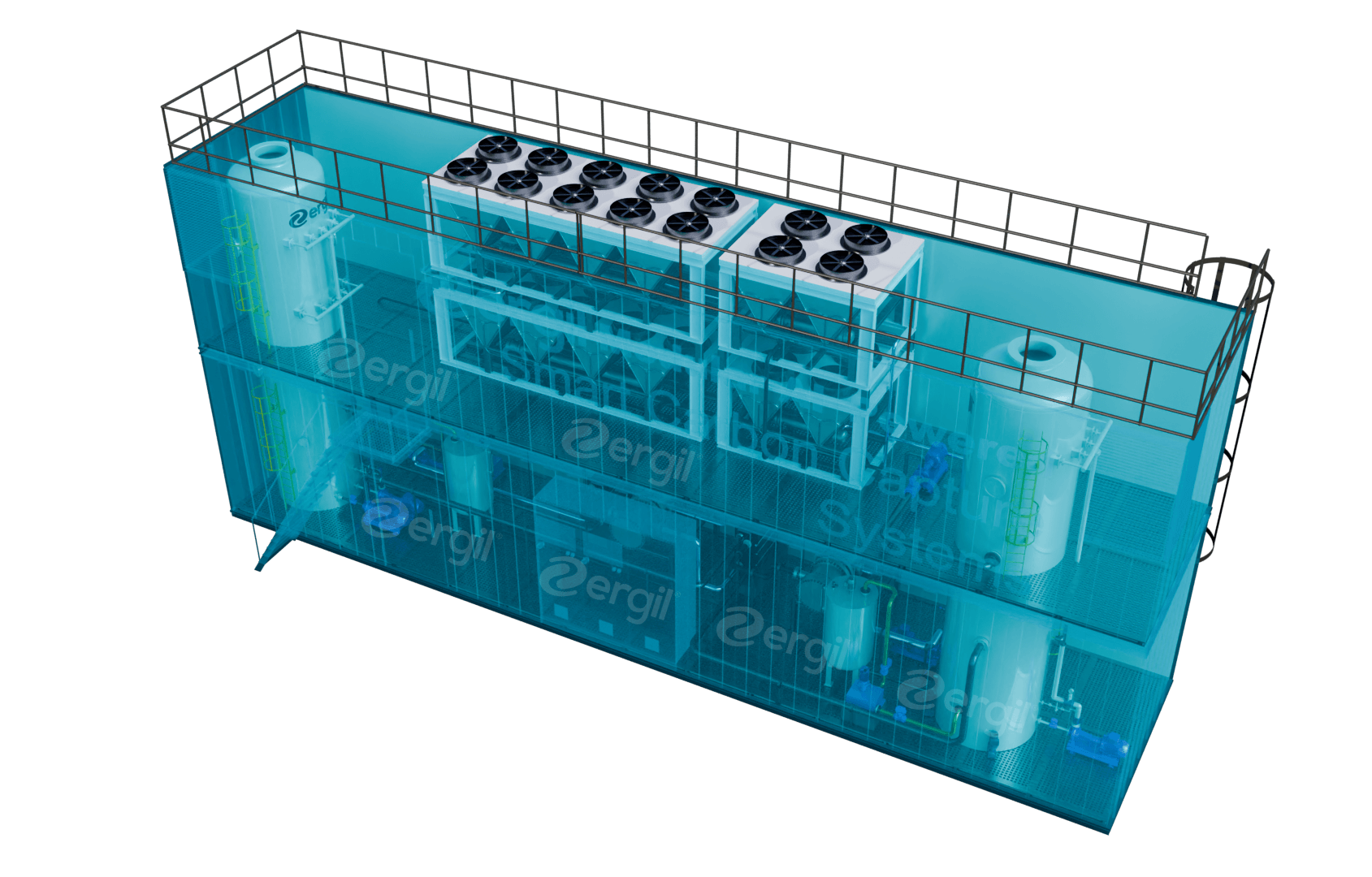

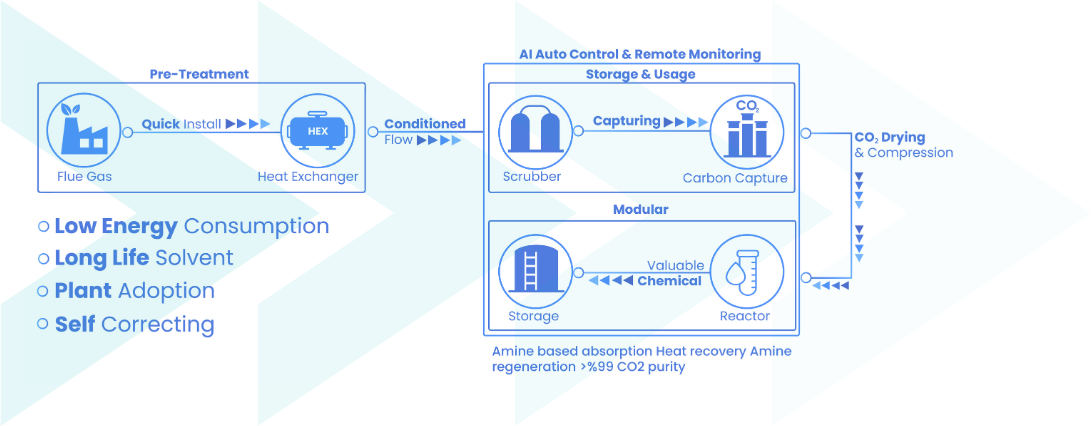

ERGIL delivers the full carbon capture process chain with in-house design and manufacturing. From pre-treatment and cooling to absorption and finally regeneration & compression, every stage is built by ERGIL for maximum efficiency, reliability, and cost savings.

Smart Design. Real Efficiency.

How We Achieve It?

ERGIL combines proven scrubber technology with advanced AI control to deliver reliable, modular carbon capture systems. Each stage — from gas pre-treatment to CO₂ regeneration — is engineered and built in-house for seamless integration and maximum performance. Smart heat recovery, optimized solvent management, and real-time monitoring extend amine life, lower OPEX, and ensure >99% capture efficiency.

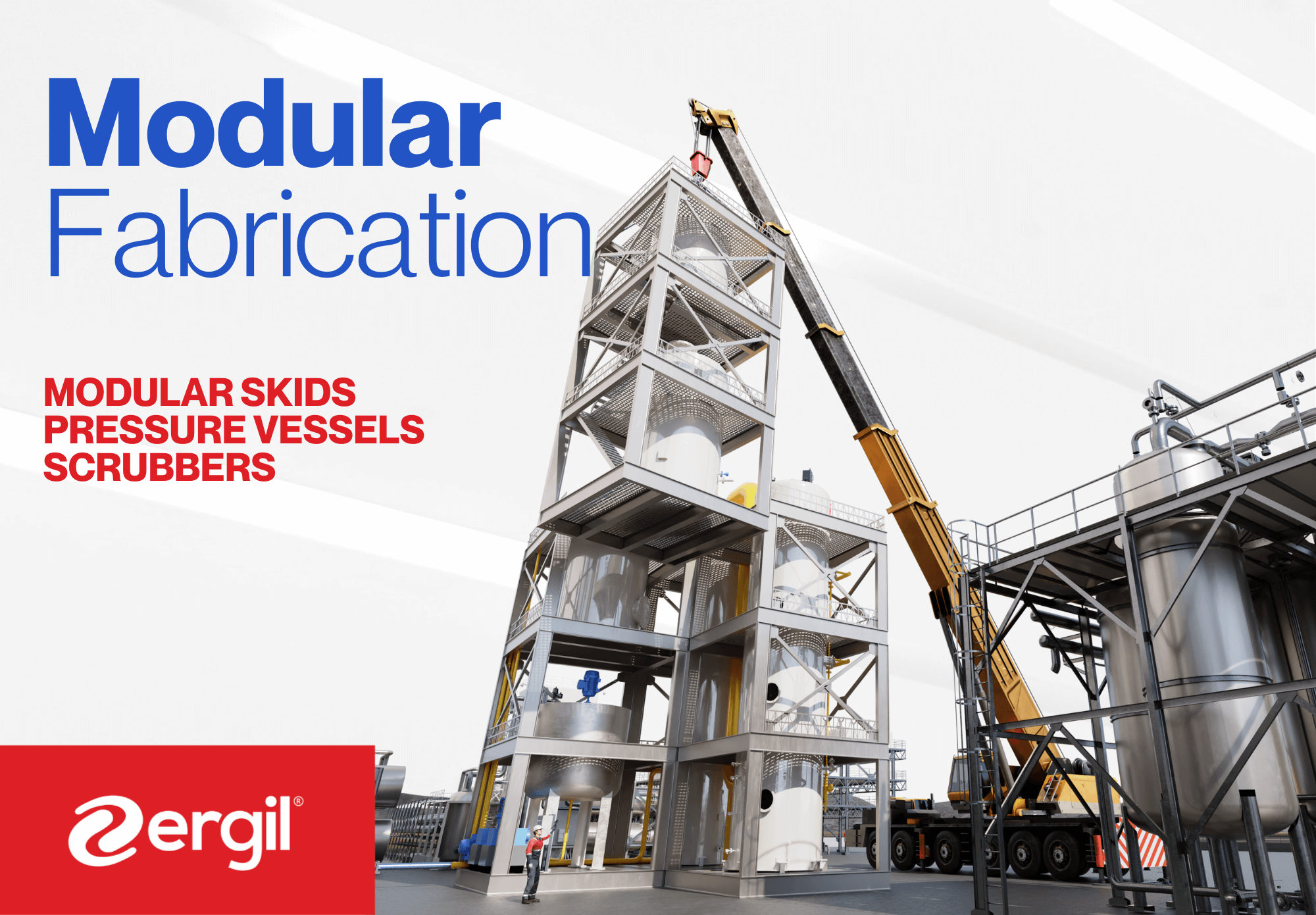

Ergil, delivering excellence in industrial solutions.

Ergil engineers and manufactures process & environmental equipment and modular skids at our 35,000 m² facility in Mersin, Türkiye. For 40+ years, we have delivered scrubbers, separators, pigging systems, and tank-safety equipment (flame arresters, PVVs) for oil & gas, chemicals, power, and carbon-capture projects.

We combine in-house design, machining, welding, blasting/painting, and testing with rigorous QA/QC and full material traceability.

All equipment is built to international codes (ASME/EN/API) and verified through client-witnessed FAT/SAT. Our multi-disciplinary team supports the full lifecycle—from sizing/simulation to commissioning and remote monitoring.

|

|

|

|

| Challenge | 2,700 m³/h process gas with HCl 680 ppm and SO₂ 500 ppm. | Chemical and odor emissions on a common header. | Atmospheric acid gases and loss of valuable process streams. |

|---|---|---|---|

| Solution | Two 2-stage wet packed scrubbers with a single optimized reagent program; 24/7 operation with cyclic chemical tank. | Two-stage wet packed scrubber in a single unit using dual-purpose chemistry to minimize chemicals/water; 24/7 operation. | Two x 2-stage scrubbers + chemical reactor to neutralize emissions and reclaim by-products back into the process. |

| Impact | ≥99% removal, stable for 2+ years, lower OPEX and compact footprint. Ovens/reactor lines integrated. | ≥99% abatement, 3+ years consistent performance; OPEX and space savings. | ≥99% chemical emission removal, 2+ years stable operation; recovery adds value with no extra major CAPEX. |

| Capture Link | Acid gas removal protects downstream CO₂ capture (amines/membranes) and improves solvent life. | Clean pre-treatment reduces solvent degradation and odor carry-over in CO₂ capture trains. | Lower acid-gas load extends CO₂ capture unit stability and uptime. |