Separator & Filter Vessels

ERGIL provides custom-made turn-key modular process skid systems for any project.

As a single source for plug and play systems, ERGIL can reduce your project cost and time drastically. ERGIL is a specialist designer and manufacturer with extensive experience providing technically advanced process equipment to industry sectors including oil & gas, petrochemical, chemical, pharmaceutical, agro, wastewater treatment, utilities and mining.

Process Guarantee Even for Complicated Applications

Thanks to our in-house process engineering capabilities and experienced team, we are ready for any challange. Our processed guaranteed design and engineering services will lower your costs and increase production. Industry is frustrated with non-performance equipment and waste millions of dollars during operations and modernization. We avoid such process related mistakes with our in-depth industry process knowledge and help our customers to work with high productivity.

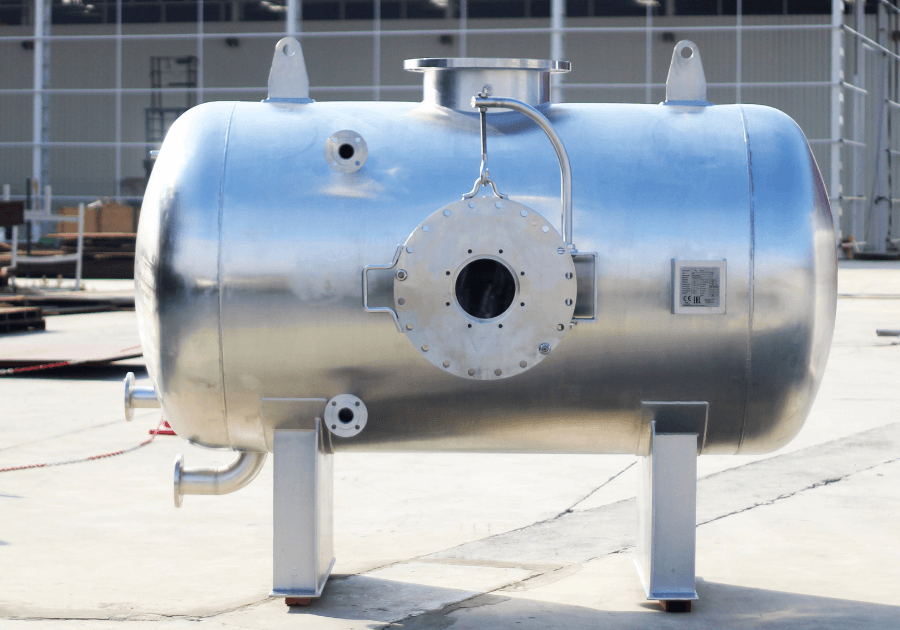

Separator & Filter Vessels

Separating Fluid Phases and Purifying Process Streams

Separator & Filter Vessels are essential equipment used in industries to separate different phases of fluids and remove impurities. These vessels effectively separate oil and water, gas and liquid, and other fluid mixtures.

Modular Process Skid Equipment

ERGIL provides custom-made turn-key modular process skid systems for any project. As a single source for plug and play systems, ERGIL can reduce your project cost and time drastically.

We can reduce your site activities and reduce your risk by supplying single or multiple units from our world-class manufacturing faclity.

With modular process skid equipment your workload will decrease and your efficiency at the site will increase.

Our equipment is designed to contribute your productivity and to ease your works. Its modular structure consists of all of your need to run your system effectively.

What is a modular process skid (MPS)?

A modular process skid is a combination of equipment that is connected to a frame.

It can be a small frame consisting of a pump or a complicated high rise system that has multiple mechanical components; such as pressure vessels, boilers, heat exchangers, storage tanks, pumps, compressors, steel structures and interconnecting pipelines as well as electrical.

What are the benefits of modular process skid equipment?

Manufacturing, and building a system on the site is very costly, slow and not safe compared to the well-managed fabrication shop. Investors and contractors are looking for ways to reduce the cost, risks and construction time, thus building industrial facilities with modular skids has become more and more popular.

Separator & Filter Vessels Models

Request A Quote

Do you need a quick quotation? Fill out the below form and expect our reply soon

Projects

Discover Our Global Success Stories: Join the Journey of Inspiration!

News, Events & Case Studies

Dive into a World of Knowledge and Insight: Explore Our News, Events, Articles, and Case Studies!

Separator & Filter Vessels FAQ's

Find Out More About Us

Our people are our biggest asset but the only way to unlock their potential is to invest in the right business systems that encourage innovation.

40+ Years in Business

40+ Years in Business More than 40 years of experience

Easily Reachable

Worldwide Offices and Representatives

Superior After Sales Support

Long-term business partnerships

Certifications ATEX, ASME, ISO, CE

High-end Production Facility

35,000 square meter manufacturing facility

Being leader in manufacturing better, safer, and economical products

Contribute positively to our communities and environments well as to ensure highest level of customer satisfaction through the highest standards of excellence in our products and services, and comprehensive environmental regulations. Working everyday for the creation of better products that protects environment, people and assets.

Our history begins in 1938 and goes on together with all our parties.

- 1983 - Founded

- 1987 - Added 100. product to its portfolio

- 1991 - Certified products and services

- 2005 - Opened its first international office

- 2010 - Became market leader in 11 countries

- 2010 - Invested heavily in new manufacturing facility

- 2015 - Build one of the biggest R&D in its-field

- 2018 - Became part of Äager