Hydrogen Storage Solutions

High-Pressure Type I Steel Cylinders & Modular Bundle Systems

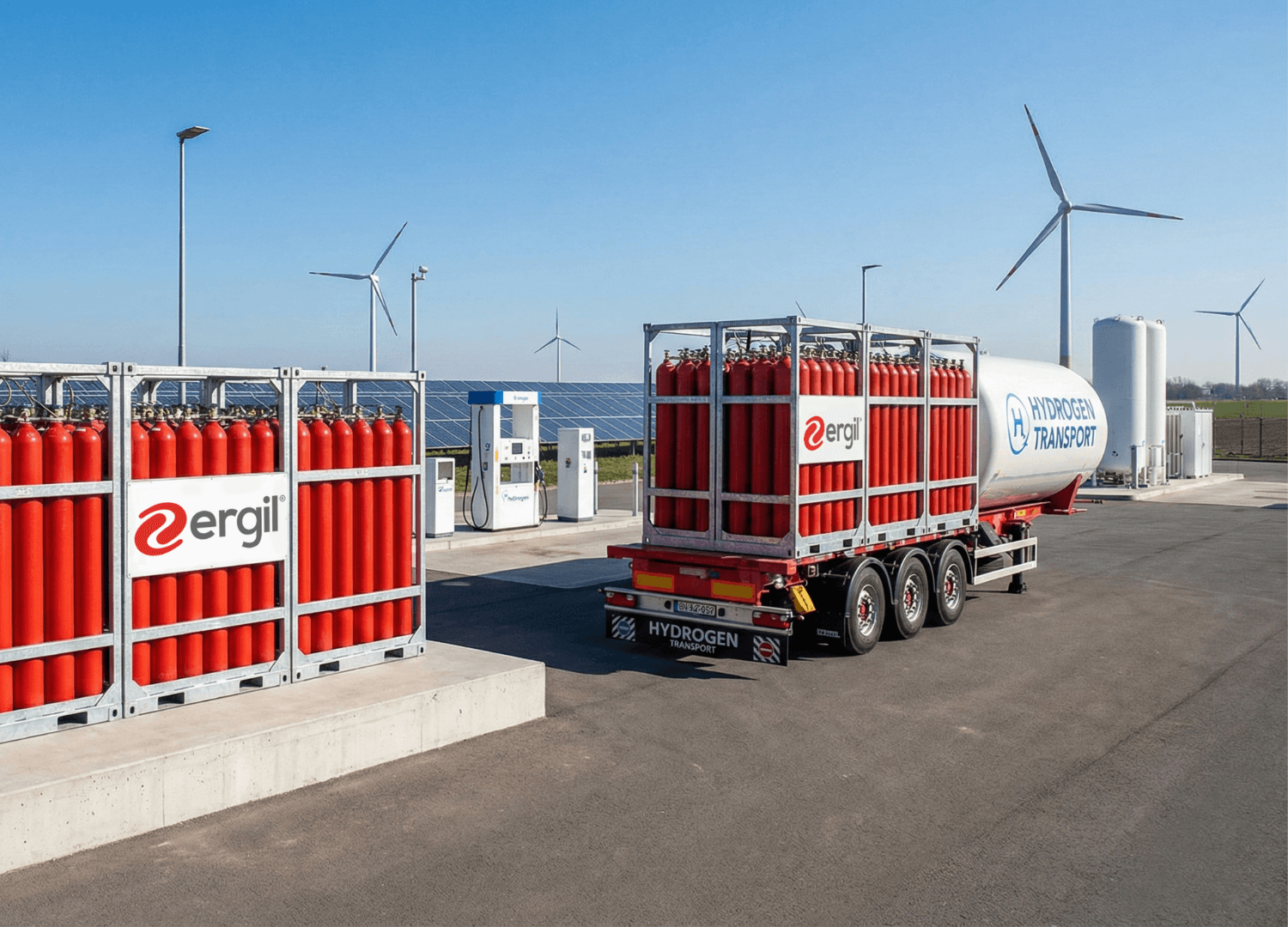

Hydrogen storage is a critical component in enabling fuel cell systems for stationary power generation, industrial applications, and transportation. Our systems are engineered for safety, structural integrity, and integration flexibility.

200 bar

Max Working Pressure

46 kg

Max Bundle Capacity

100%

Recyclable Materials

Hydrogen Storage Solutions

High-Pressure Type I Steel Cylinders

& Modular Bundle Systems

Hydrogen storage is a critical component in enabling fuel cell systems for stationary power generation, industrial applications, and transportation. Our systems are engineered for safety, structural integrity, and integration flexibility.

Type I Steel Hydrogen Cylinders

Design & Construction

Manufactured entirely from high-strength steel, Type I cylinders are designed to ensure maximum durability under high-pressure conditions. Unlike composite alternatives, the all-steel construction provides superior mechanical durability and resistance to deformation.

- Material Integrity: Constructed using high-quality alloy steels (including SS-316 or Carbon Steel) specifically selected to minimize the risk of Hydrogen Induced Cracking (HIC) and surface embrittlement.

- Thermal & Fire Resistance: The steel structure maintains integrity under elevated temperatures and offers higher fire resistance compared to composite cylinders.

- Lifecycle Management: Cylinders can be periodically tested, inspected (via standard NDT methods), and recertified in accordance with international standards, ensuring a long service life.

- Sustainability: The units are 100% recyclable, supporting circular economy strategies.

Modular Bundle & Cascade Systems

System Architecture

For applications requiring higher volume capacities, Ergil offers Bundle Systems—a modular solution where multiple Type I cylinders are connected in parallel11. These systems are designed for ease of scalability and efficient space management.

- Integrated Manifold: Ensures homogeneous gas distribution and equal pressure across all cylinders, providing a continuous gas supply

- Configuration: Bundles typically range from 12 to 36 cylinders, offering a hydrogen storage capacity of up to ~46 kg per bundle.

- Fixed Cascade Systems: Ideal for stationary applications such as hospitals, laboratories, and industrial facilities. These systems connect cylinders in a series or staged layout to ensure uninterrupted flow for critical operations

- Safety Monitoring: Systems are equipped with pressure relief valves, leak detection, and continuous monitoring of pressure and temperature parameters.

Technical Specifications

General Data & Performance Parameters

- Cylinder Type: Type I (Seamless Steel)

- Standard Materials: C-Mn and Cr-Mo low-alloy steel; SS-316 options available

- Manufacturing Standards: ISO 9809-1 / ISO 11120

- Compliance: ASME Section VIII Division 1, PED 2014/68/EU, TPED

- Safety Factor: Burst pressure ≥ 3× working pressure

| Parameter | Specification |

|---|---|

| Max Working Pressure | Standard 200 bar (Customizable: 35-200 bar) |

| Volume per Cylinder | 10 - 200 Liters (Standard: 80L) |

| Bundle Capacity (12 Cyl) | ~15 kg Hydrogen Gas |

| Bundle Capacity (36 Cyl) | ~46 kg Hydrogen Gas |

| Orientation | Vertical (Fixed/Stationary) or Horizontal (Mobile/Transport) |

| Surface Treatment | Galvanized or Powder-Coated |

Applications

Ergil Hydrogen Storage Systems are engineered for diverse sectors requiring stable and safe energy carriers:

- Industrial: Hydrogen production facilities, buffer tanks, and pilot systems.

- Energy: Stationary fuel cell power plants, renewable energy storage, and microgrid solutions.

- Mobility Infrastructure: Filling stations and fleet refueling for buses/trucks.

- Process Industries: Welding, cutting, chemical processing, and medical gas supply.

Engineering & Safety Features

- Hydrogen Embrittlement Resistance: Materials are selected per ISO 11114-4 standards to withstand cyclic loading.

- Internal Surface Quality: Precision-machined interiors prevent micro-crack initiation.

- Emergency Controls: Equipped with emergency shut-off valves for immediate isolation in hazardous scenarios.

- Static Grounding: Integrated grounding systems to minimize ignition risks during gas dispersion.