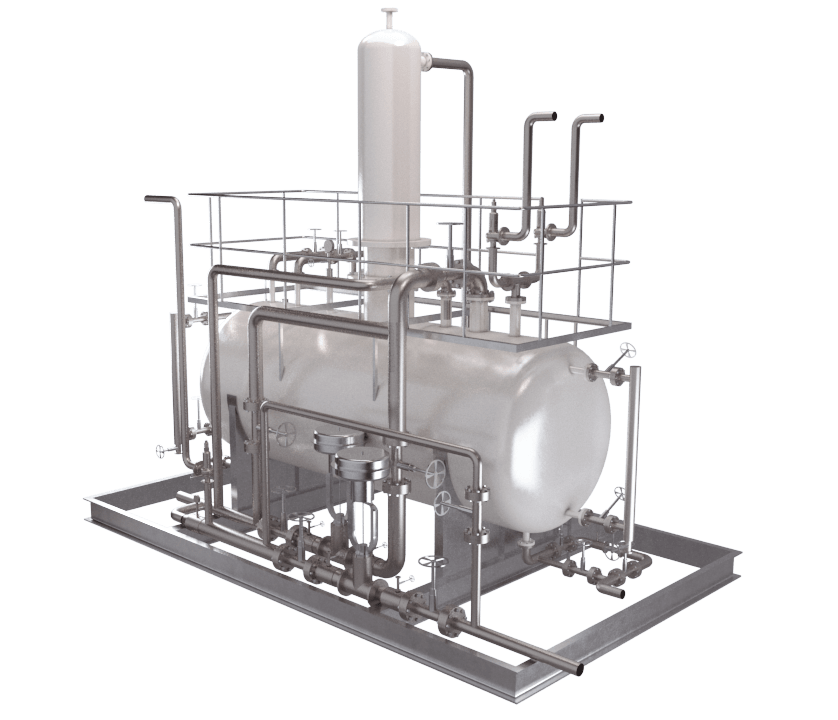

Feedwater Tank is designed in accordance with ASME Boiler and Pressure Vessel Code (BPVC) Section VIII Division 1, HEI Standards (Section 5.2), design conditions are given in the Data Sheet for Deaerator and Feed water Storage Tank and Site-Specific Conditions (i.e. ambient conditions, wind loads, seismology …etc) are given in General Project Requirements Specification. Both Deaerator and Feedwater Storage Tank shall have ASME Code Stamp.

Deaerator and Feedwater Storage Tank shall be designed for STG valves wide open (V.W.O) load corresponding to peak Combined Cycle Plant output and also capable of continuous and safe operation over the full range of steam and water temperatures and pressures.

Heater supports shall be suitable to withstand forces and moments imposed on heater nozzles by the Owner’s attached piping.

Deaerator and also Feedwater Storage Tank shells are designed for working pressures from full vacuum (FV) to the design pressure as per customer requirement.

Pipes and nozzles shall be designed to distribute condensate over trays for concurrent full internal vacuum and full exterior deaerator pressure to withstand pressure resulting from liquid flashing in a pipe before nozzles or spray holes, opening control valve that supplies condensate to empty spray pipe, or filling the empty system. Design trays safely withstand impact energy of condensate on trays resulting from the above-described pressure peaks.

Deaerator and Feedwater Storage Tank are designed to minimize noise and vibration at all flow rates up to and including maximum capacity, during rapid load changes, and for entering feedwater temperature ranging from steady state to the normal condenser hot well temperature.

All components having safe working stresses which are not exceeded during all conditions of operation (i.e. startup, steady state at any load from zero to full load, transient conditions) and forces caused by flashing of liquid in the storage tank. Trays, tray enclosure, and support members shall be designed to withstand maximum pressure differential across the trays and tray enclosure during any condition of operation. Transient conditions which occur upon sudden load rejection, assuming that all steam flow has stopped while condensate continues to enter the deaerator at the maximum flow rate for transient or condensate control valve failed wide open, resulting in pressure differential across the tray enclosure.